- Introduction

- Controllers

- Feedback

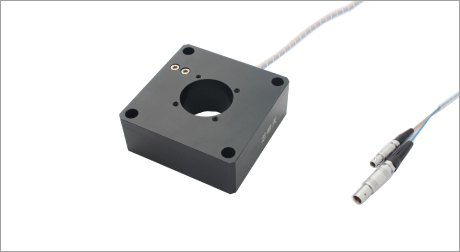

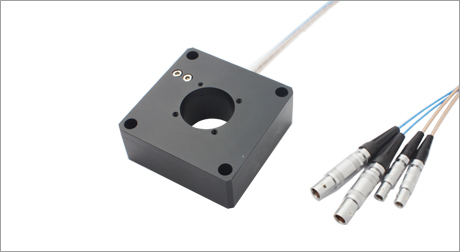

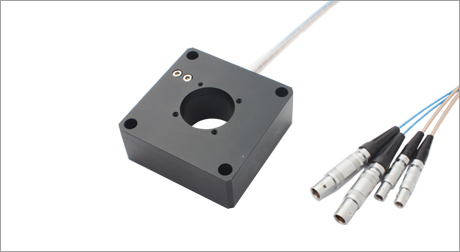

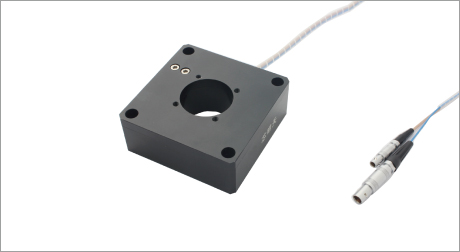

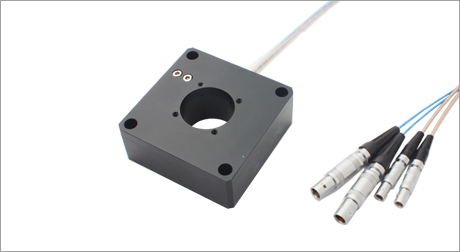

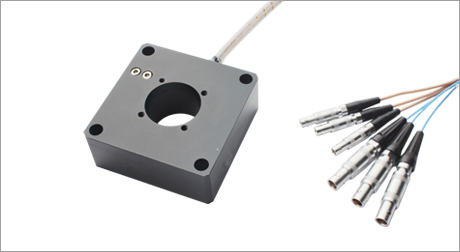

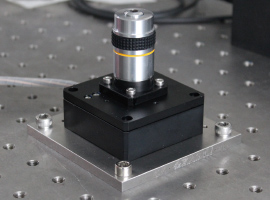

P12.XYZ-D3 is XYZ-axes motion piezoelectric scanner, with compact structure, external dimensions of 70×70×24mm, and a stroke of up to 100μm. Piezoelectric drive, frictionless, flexible hinge guide system enables this series of products to achieve nano-level resolution, millisecond response time, and the aperture is Φ35mm, which is suitable for sample positioning in microscopy and scanning.

Features

|

|

|

|

|

|

|

|

|

|

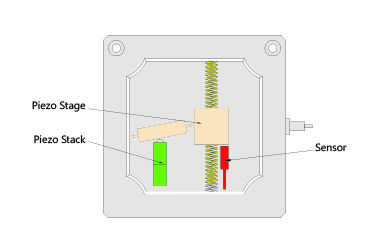

Moving part

|

Amplified-driving

|

Open/closed Loop Curve

|

|

Small Size Large Displacement

P12 adopts amplified mechanism, ultra-small volume shape, and could achieve scanning range up to 100μm, aperture could be selected 25mm(35mm is optional). |

Application case-Inverted Piezo Scanner

|

Applications

|

|

|

|

|

|

|

|

|

P12 series

Aperture: φ25mm version:

|

|

Aperture: φ25mm version:

|

|

|

|||

|

|

| Technical data | ||||

|

Models |

End with S:Closed loop |

P12.XYZ100S-D |

P12.XYZ100K-D |

Units |

|

End with K: Open loop |

||||

|

Active axes |

X、Y、Z |

X、Y、Z |

|

|

|

Motion and Positioning |

||||

|

Travel range(0~120V) |

80 |

80 |

µm±20% |

|

|

Max.travel range(0~150V) |

100 |

100 |

µm±20% |

|

|

Integrated sensor |

SGS |

- |

|

|

|

Aperture |

Ø25/Ø35 |

Ø25/Ø35 |

mm |

|

|

Resolution |

7 |

4 |

nm,typ. |

|

|

Closed-loop linearity |

0.15 |

- |

%F.S. |

|

|

Repeatability |

0.1 |

- |

%F.S. |

|

|

Pitch/Yaw/Roll |

<15 |

<15 |

µrad |

|

|

Mechanical properties |

||||

|

Push/pull force capacity in motion direction |

20/4 |

20/4 |

N |

|

|

Stiffness in motion direction |

0.2 |

0.2 |

N/µm±20% |

|

|

Unloaded resonant frequency |

0.15 |

0.15 |

kHz±20% |

|

|

Unloaded step time |

30 |

0.8 |

ms±20% |

|

|

Unloaded operating frequency* |

10% travel |

50 |

>50 |

Hz±20% |

|

100% travel |

5 |

>5 |

||

|

Load capacity |

Horizontal |

0.6 |

0.6 |

Kg |

|

Vertical |

0.03 | 0.03 | ||

|

Inverted |

0.03 | 0.03 | ||

|

Drive properties |

||||

|

Electrical capacitance |

1.8 |

1.8 |

μF/axis±20% |

|

|

Miscellaneous |

||||

|

Operating temperature range** |

-20~80 |

-20~80 |

°C |

|

|

Material |

Steel, Aluminum |

Steel, Aluminum |

|

|

|

Dimensions(L×W×H) |

70×70×24 |

70×70×24 |

mm |

|

|

Mass |

300 |

300 |

g±5% |

|

|

Cable length |

1.5 |

1.5 |

m±10mm |

|

|

Sensor/voltage connection*** |

LEMO |

LEMO |

||

*If this operating frequency is very close to or exceeds the resonant frequency, it is recommended to use it much less than the resonant frequency. If it is necessary to work at this frequency, the input voltage must be small enough, and it must be gradually debugged from the minimum signal.

**Custom ultralow temperature and ultrahigh vacuum versions are available.

***Custom connector is available.

Note: The parallelism of the moving platform is about 20 μm, and the roughness is about 1.6 to 3.2. Please contact the sales engineer for confirmation before purchase.

Note: Max driving voltage could be -20V~150V, Recommended voltage 0~120V for long-term operation to extend lifetime. Technical data are measured by CoreMorrow E00/E01 series piezo controller.

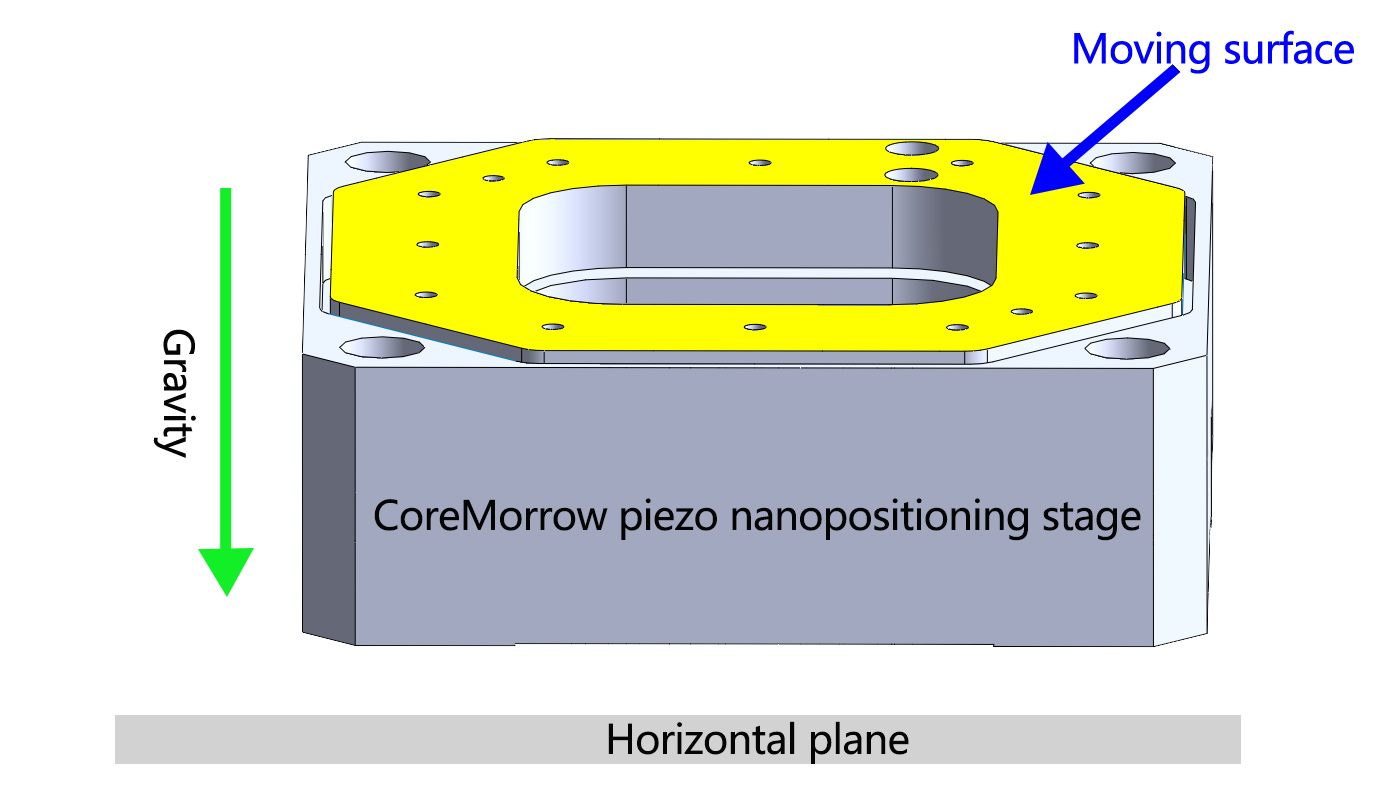

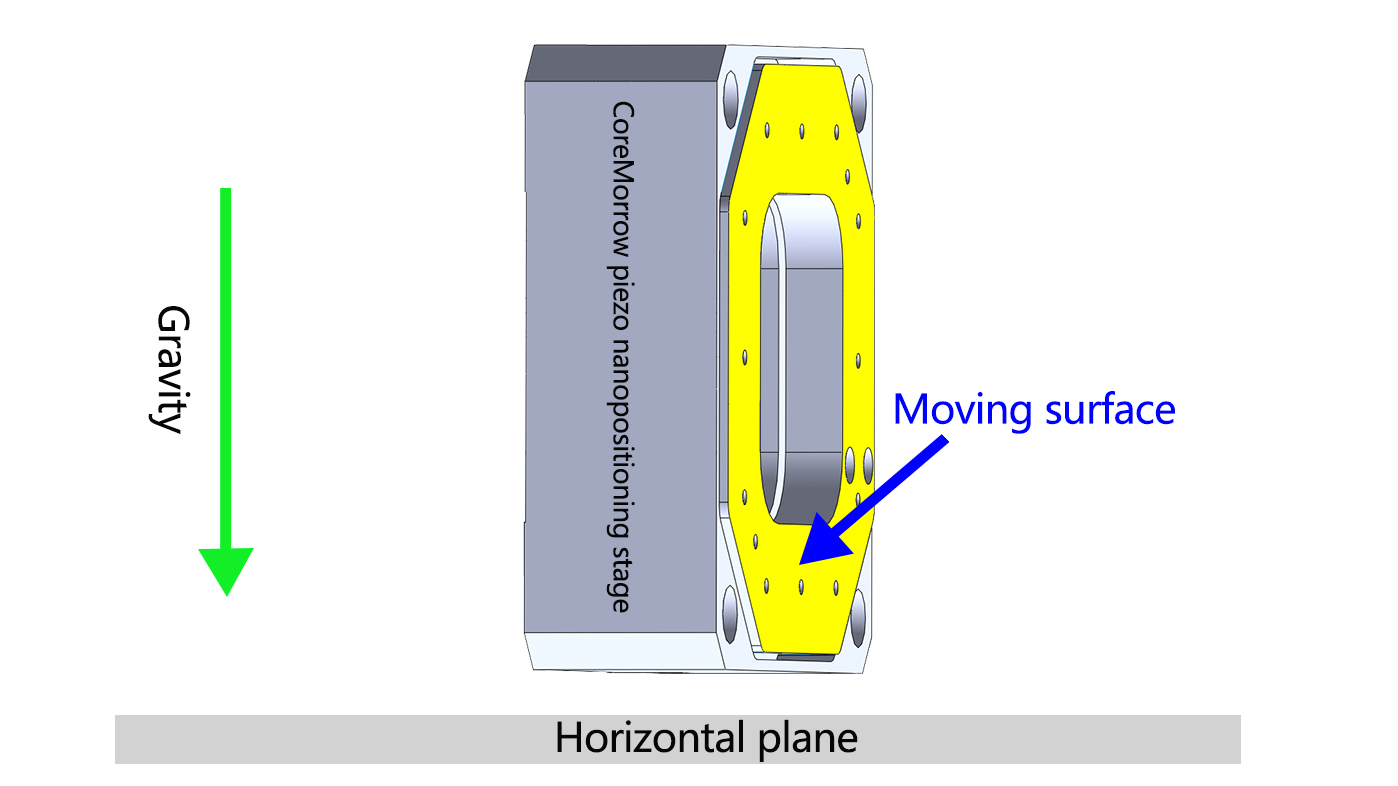

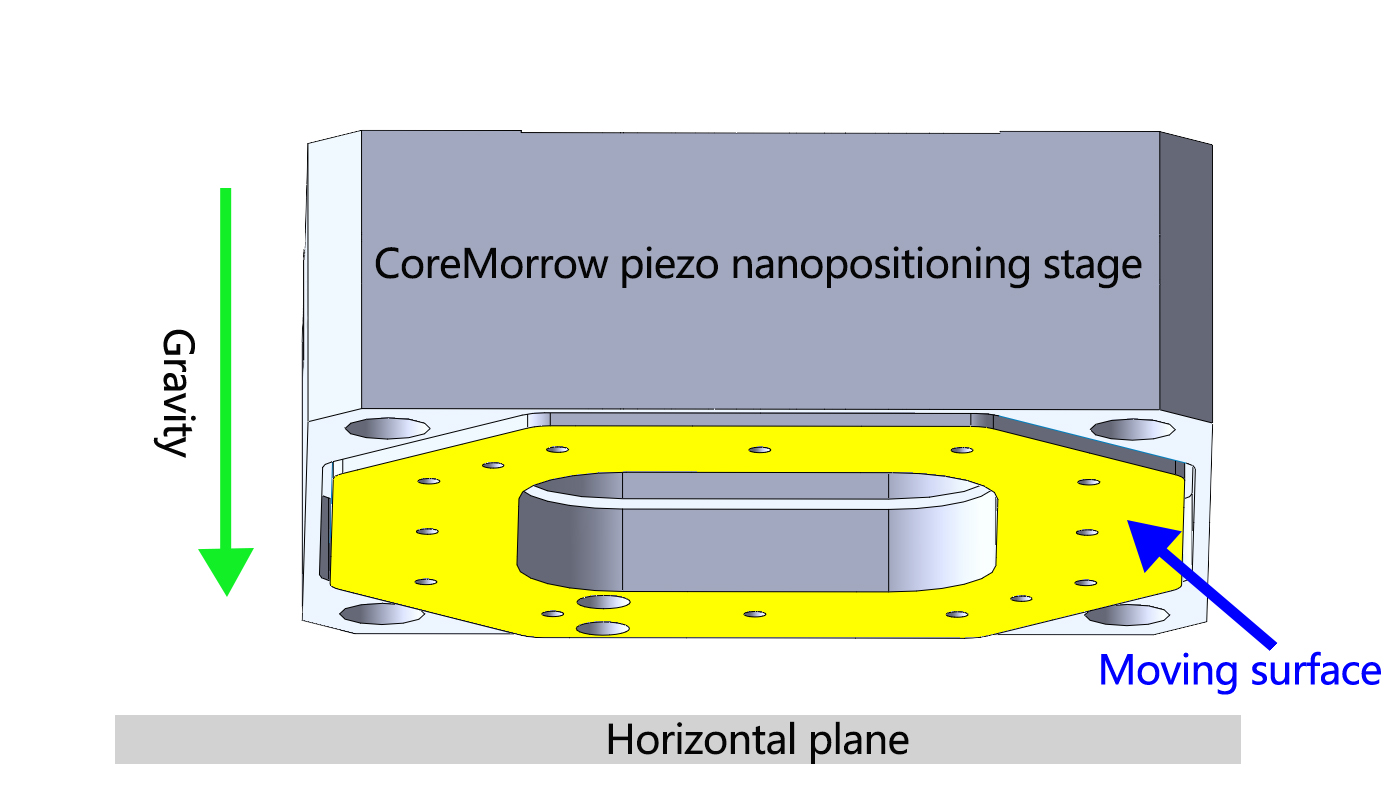

| Mounting Method |

Horizontal Mounting |

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

|

|

||||||||||||

|

|