- Introduction

- Controllers

- Feedback

P93 could realize max stroke to 81μm. It could be equipped with LVDT sensor or CAP sensor. The sensor outputs 0-10V voltage signal corresponding to the 0μm to full stroke of the stage.

Characteristics

|

|

|

|

|

|

|

|

|

|

|

Dust and Droplet Proof On Request

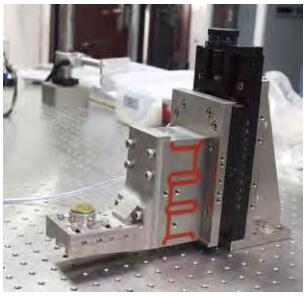

Fast tool stage is dust- and drip-resistant, allowing it to work in humid environments. The stage body material is made of stainless steel to ensure the stability during processing, the structure is stable and reliable, and the machining accuracy is not affected by the vibration. |

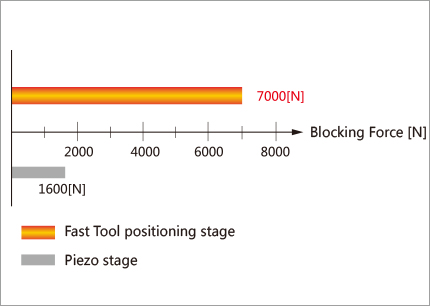

Large Blocking Force Blocking force of piezo actuator in fast tool positioning stage is several times of other piezo actuator in piezo stage.

|

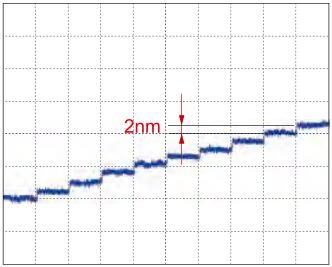

Closed loop Resolution Unlike vibration machining, the tool position could be feedback controlled by sensor for nanometer resolution.

|

|

Customized Macro Micro Stage

|

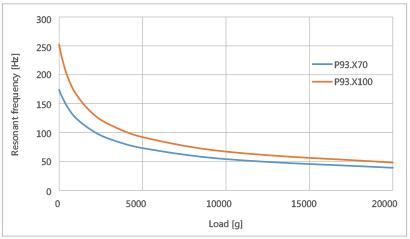

Freqency VS Load Curve

|

Applications

|

|

|

|

|

| Technical data | |||||

|

Models |

C/L-Closed loop |

P93.X70C |

P93.X70L |

P93.X70K |

Units |

|

K-Open loop |

|||||

|

Active axes |

X |

X |

X |

|

|

|

Drive control |

1 driving channel 1 sensing channel |

1 driving channel 1 sensing channel |

1 driving channel |

|

|

|

Motion and Positioning |

|||||

|

Travel range(0~120V) |

65 |

65 |

65 |

µm±10% |

|

|

Max.travel range(0~150V) |

81 |

81 |

81 |

µm±10% |

|

|

Integrated sensor |

CAP |

LVDT |

- |

|

|

|

Resolution |

2.5 |

10 |

1 |

nm,typ. |

|

|

Closed-loop linearity |

0.05 |

0.1 |

- |

%F.S. |

|

|

Repeatability |

0.03 |

0.05 |

- |

%F.S. |

|

|

Pitch/Yaw/Roll |

<15 |

<15 |

<15 |

µrad |

|

|

Mechanical properties |

|||||

|

Push/pull force capacity in motion direction |

400/50 |

400/50 |

400/50 |

N |

|

|

Stiffness in motion direction |

5 |

5 |

5 |

N/µm±20% |

|

|

Unloaded resonant frequency |

0.15 |

0.15 |

0.15 |

kHz±20% |

|

|

Unloaded step time |

10 |

10 |

7 |

ms±20% |

|

|

Load capacity |

Horizontal |

20 |

20 |

20 |

Kg |

|

Vertical |

- | - | - | ||

|

Inverted |

- | - | - | ||

|

Drive properties |

|||||

|

Electrical capacitance |

15 |

15 |

15 |

μF±20% |

|

|

Miscellaneous |

|||||

|

Material |

Steel |

Steel |

Steel |

|

|

|

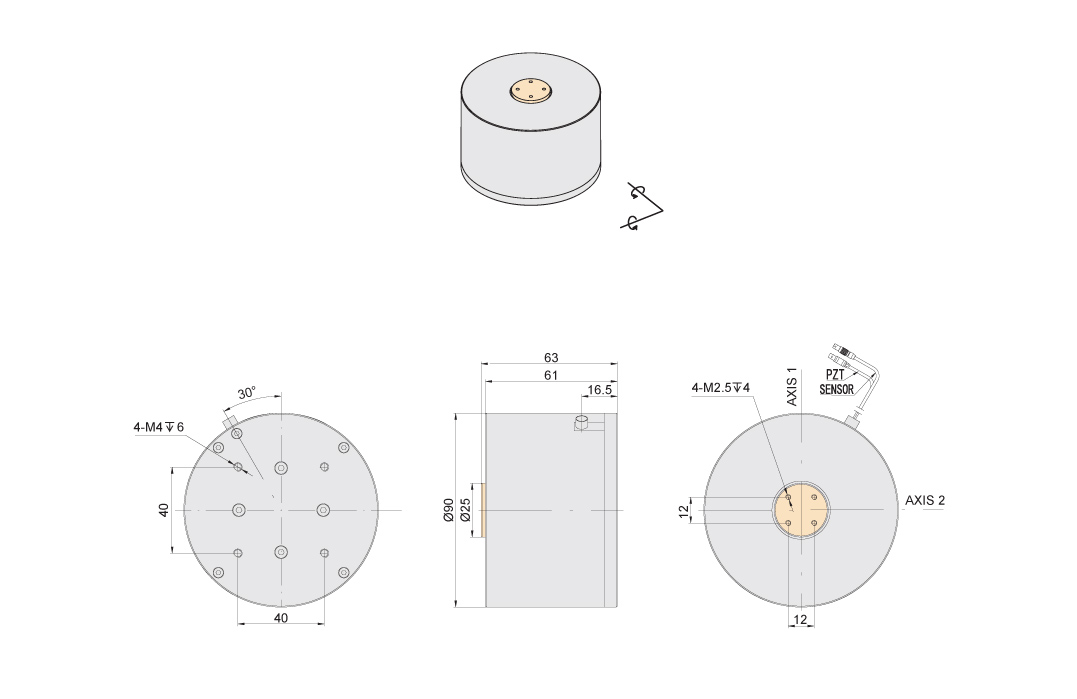

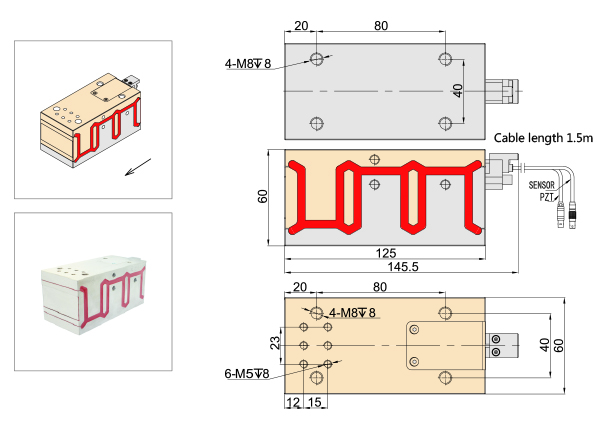

Dimensions(L×W×H) |

145.5×60×60 |

145.5×60×60 |

145.5×60×60 |

mm |

|

|

Mass |

4000 |

4000 |

4000 |

g±5% |

|

|

Cable length |

1.5 |

1.5 |

1.5 |

m±10mm |

|

|

Sensor/voltage connection*** |

LEMO |

LEMO |

LEMO |

||

** Custom ultralow temperature and ultrahigh vacuum versions are available.

***Custom connector is available.

Note: The parallelism of the moving platform is about 20 μm, and the roughness is about 1.6 to 3.2. Please contact the sales engineer for confirmation before purchase.

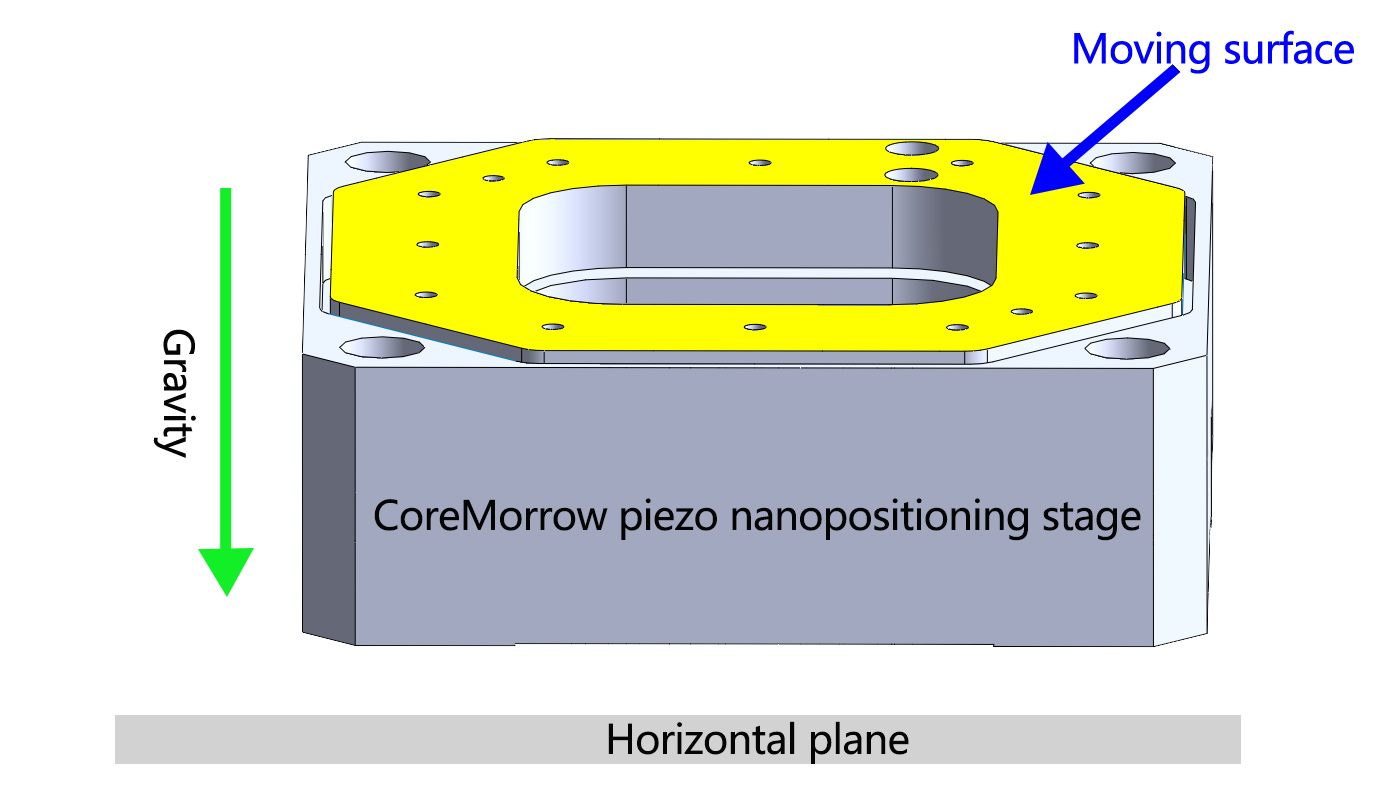

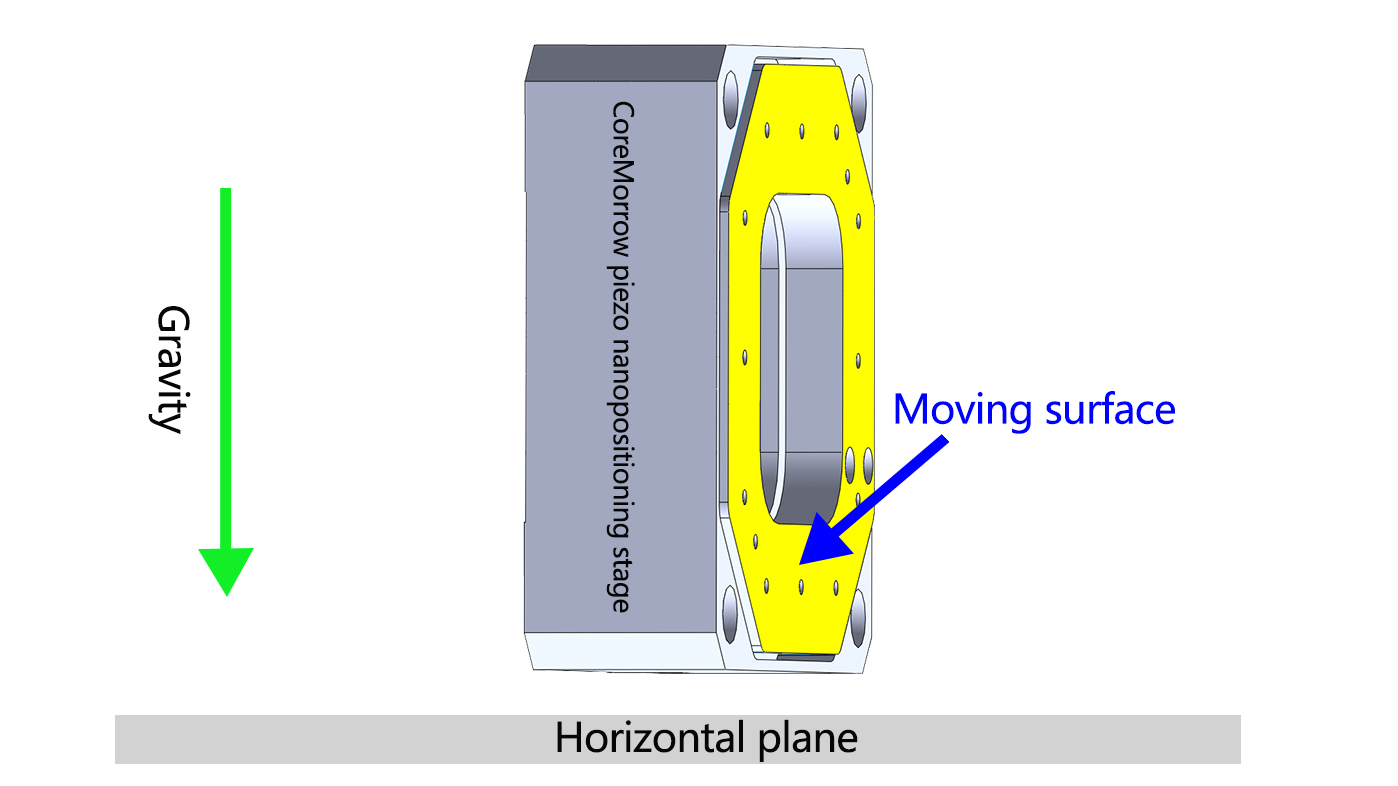

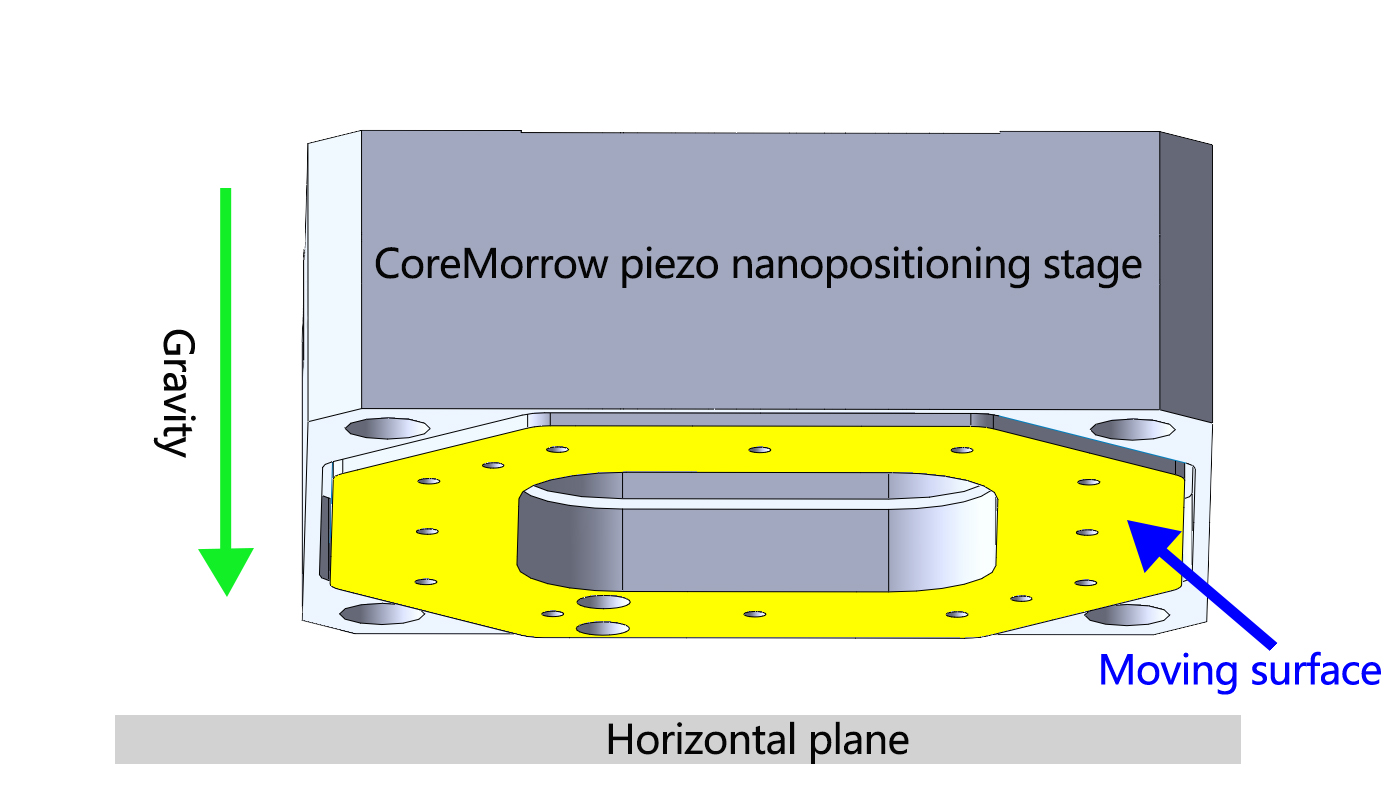

| Mounting Method |

Horizontal Mounting |

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

Recommended Controller

|

|

|

|

|

||||||||||||

|