- Introduction

- Controllers

- Feedback

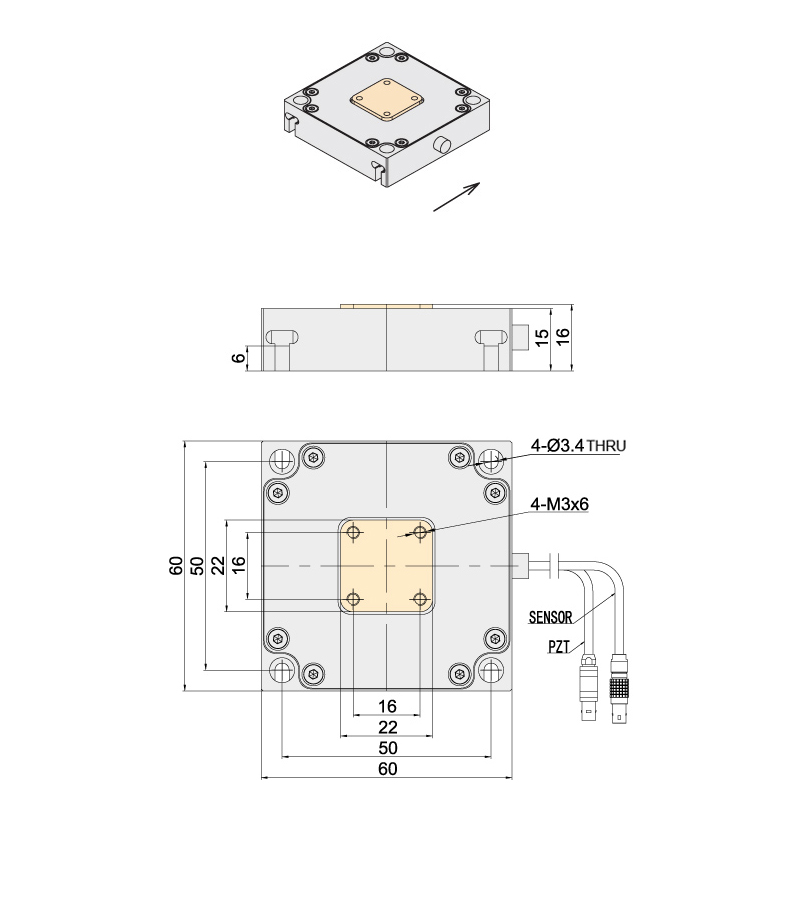

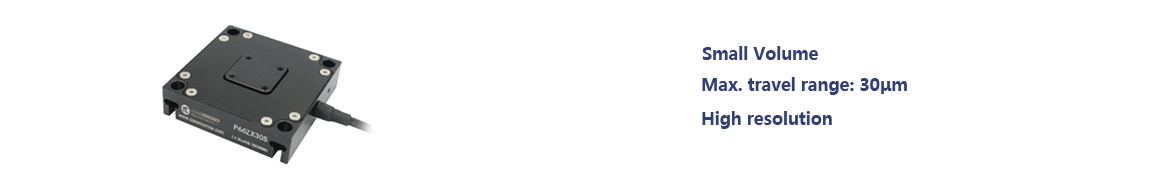

P66.X30 piezo nano-positioning stage uses piezoelectric stacks as driving source and using direct drive mechanism. It is nano-positioning system combining piezoelectric and flexible hinges. Precision, and optional high-precision sensors for closed-loop precise positioning control. This product is ideal for positioning applications such as optical path length correction in interference, sample positioning in microscopy or scanning applications, and more.

Characteristics

|

|

|

|

|

|

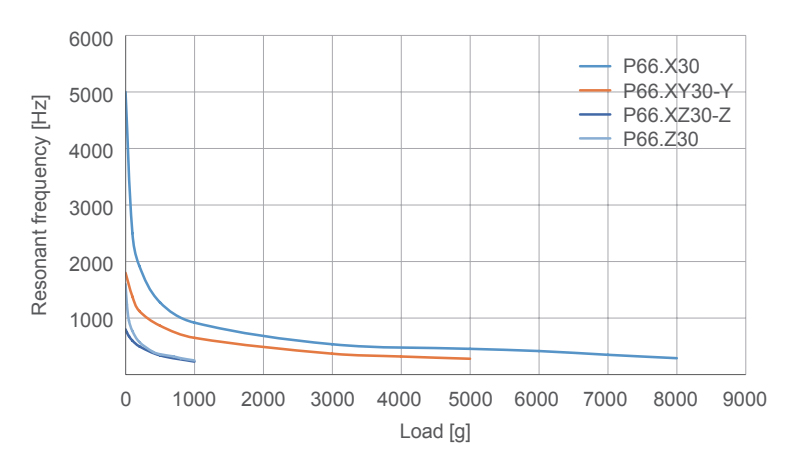

Curve

|

Open/Closed Loop Version

P66 could be selected as open-loop or closed-loop version. Closed-loop is equipped with high-resolution and fast-responding strain sensor (SGS). The device feeds back high-bandwidth, high-precision voltage signals. |

Application Cases: AFM CoreMorrow P66.XY piezo nanopositioning stage is widely used in AFM for its high response frequency, high precision and high reliability.

|

Applications

|

|

|

|

|

| Technical data | ||||

|

Models |

S-Closed loop |

P66.X30S |

P66.X30K |

Untis |

|

K-Open loop |

||||

|

Active axes |

X |

X |

|

|

|

Drive control |

1 driving channel 1 sensing channel |

1 driving channel |

|

|

|

Integrated sensor |

SGS |

- |

|

|

|

Travel range |

0~120 V |

24 |

24 |

µm±10% |

|

0~150 V |

30 |

30 |

µm±10% |

|

|

Closed/open loop resolution |

1 |

0.5 |

nm,typ. |

|

|

Closed-loop linearity |

0.1 |

- |

%F.S. |

|

|

Repeatability |

0.05 |

- |

%F.S. |

|

|

Pitch/Yaw/Roll |

<15 |

<15 |

µrad |

|

|

Stiffness in motion direction |

4.4 |

4.4 |

N/µm±20% |

|

|

Unloaded resonant frequency |

5 |

5 |

kHz±20% |

|

|

Closed-loop operating frequency(-3dB) |

600(unloaded) |

600(unloaded) |

Hz±20% |

|

|

Closed/open-loop unloaded Step time |

5 |

0.8 |

ms±20% |

|

|

Push/pull force capacity |

120/15 |

120/15 |

N |

|

|

Load capacity |

Horizontal |

8 |

8 |

kg |

|

Vertical |

0.3 | 0.3 | ||

|

Inverted |

8 | 8 | ||

|

Electrical capacitance |

3.6 |

3.6 |

μF±20% |

|

|

Material |

AL |

AL |

|

|

|

Mass |

120 |

120 |

g±5% |

|

Note: Max driving voltage could be -20V~150V, Recommended voltage 0~120V for long-term operation to extend lifetime.

Technical data are measured by CoreMorrow E00/E01 series piezo controller.

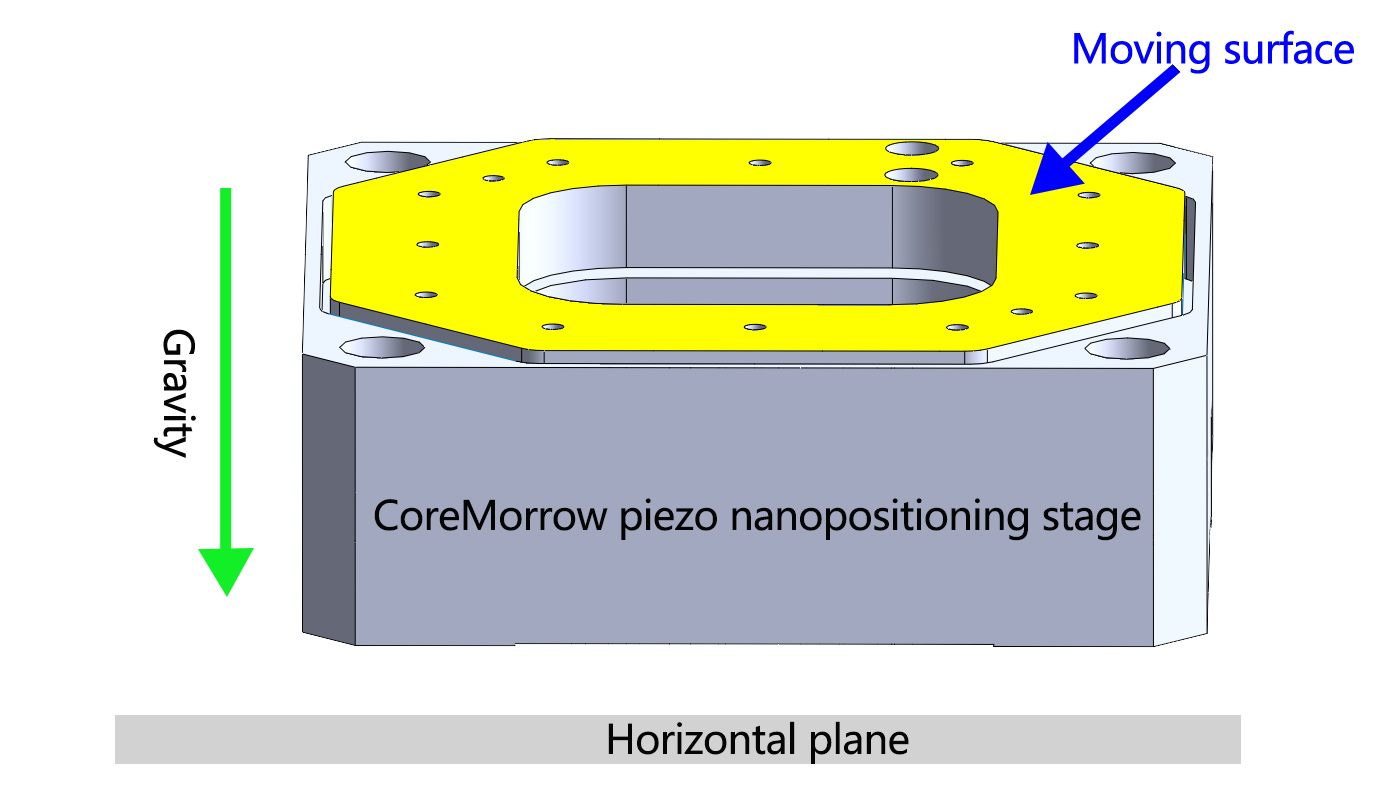

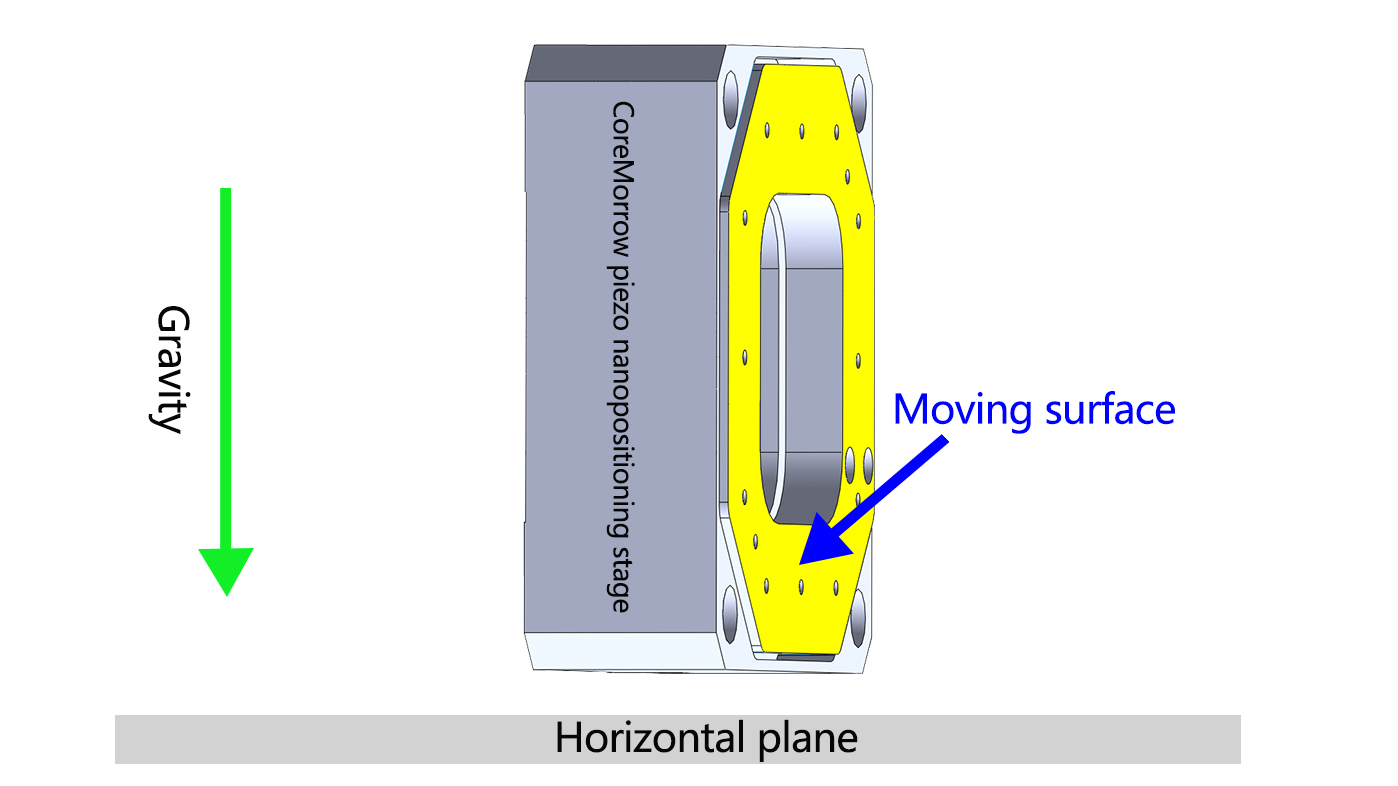

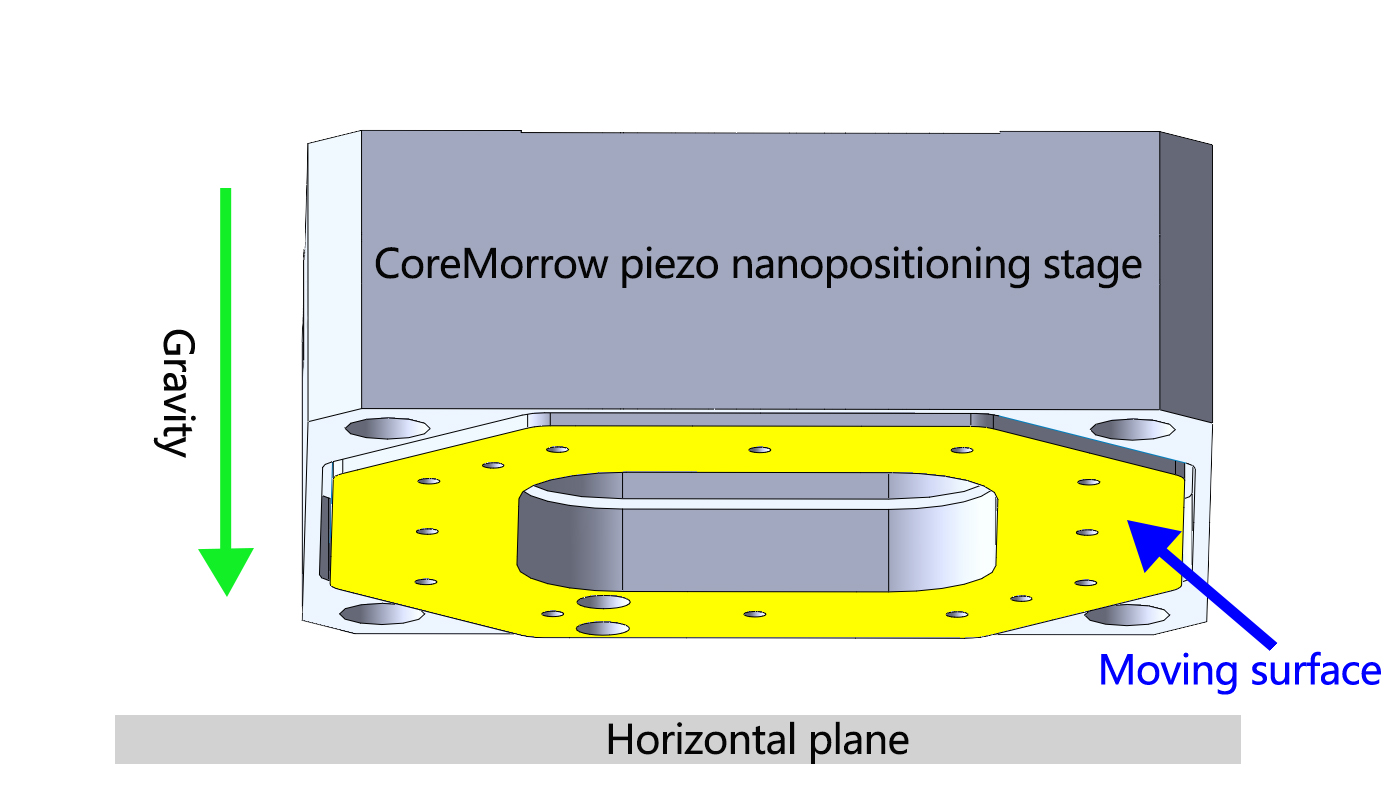

| Mounting Method |

Horizontal Mounting |

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

|

|

|||||||||||||||||