- Introduction

- Controllers

- Feedback

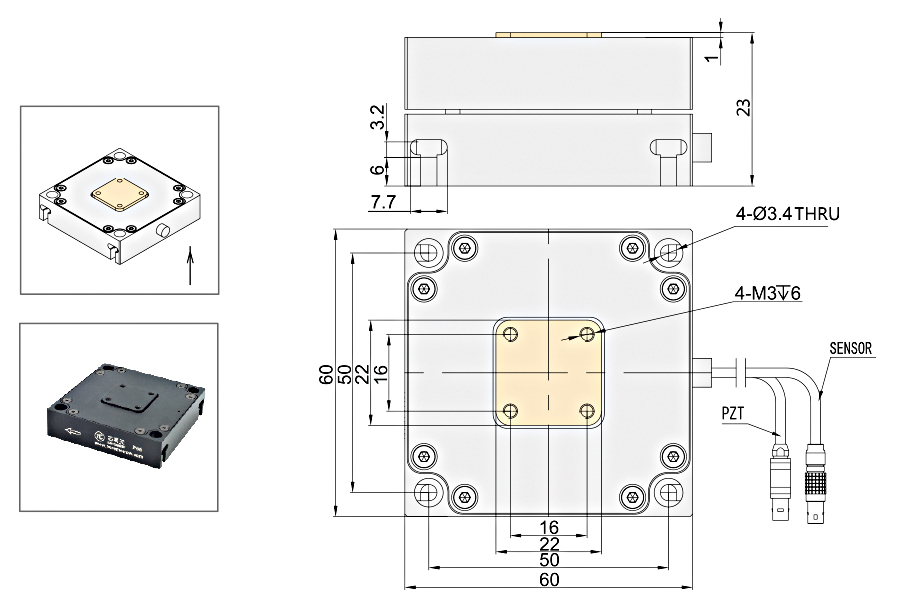

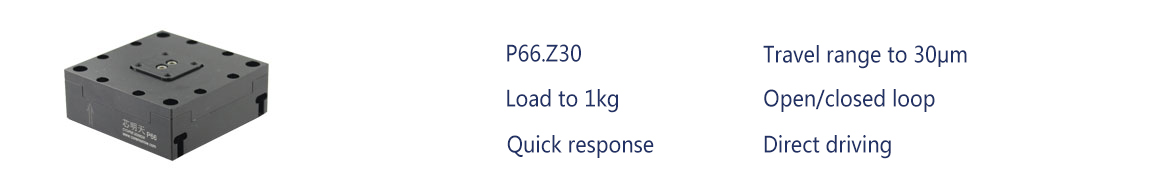

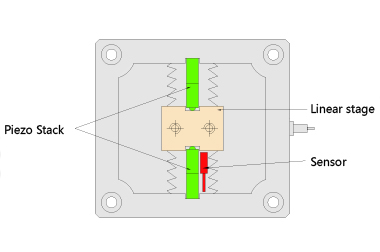

P66.Z30 is Z-axis motion using a direct driving mechanism. It is a nano-positioning system combining piezo and flexible hinges, which could reach millisecond response time, sub-nano accuracy, and optional high-precision sensors for closed-loop control. It is ideal for positioning applications such as optical path length correction in interference, sample positioning in microscopy or scanning applications, etc., and has been widely used in interference, microscopy, precision machining and other fields.

Features

|

|

|

|

|

|

Appearancem

|

Direct-driving

|

Open/Closed Loop Version

P66 could be selected as open-loop or closed-loop version. Closed-loop is equipped with high-resolution and fast-responding strain sensor (SGS). The device feeds back high-bandwidth, high-precision voltage signals. |

|

Application Cases: AFM CoreMorrow P66.XY piezo nanopositioning stage is widely used in AFM for its high response frequency, high precision and high reliability.

|

Applications

|

|

|

|

|

| Technical data | ||||

|

Models |

S-Closed loop |

P66.Z30S |

P66.Z30K |

Units |

|

Active axes |

Z |

Z |

|

|

|

Drive control |

2 driving channels 2 sensing channels |

2 driving channels |

|

|

|

Travel range(0~120V) |

24 |

24 |

μm±20% |

|

|

Max.travel range(0~150V) |

30 |

30 |

μm±20% |

|

|

Integrated sensor |

SGS |

- |

|

|

|

Closed/open loop resolution |

1 |

0.5 |

nm |

|

|

Closed-loop linearity |

0.1 |

- |

%F.S. |

|

|

Repeatability |

0.05 |

- |

%F.S. |

|

|

Pitch/Yaw/Roll |

<15 |

<15 |

μrad |

|

|

Push/pull force capacity |

30/10 |

30/10 |

N |

|

|

Stiffness in motion direction |

1.1 |

1.1 |

N/μm±20% |

|

|

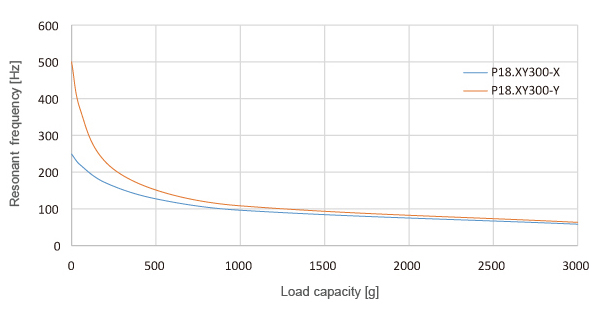

Unloaded resonant frequency |

1.4 |

1.4 |

kHz±20% |

|

|

Closed/open-loop unloaded Step time |

15 |

1 |

ms±20% |

|

|

Closed-loop operating frequency(-3dB) |

- |

- |

Hz±20% |

|

|

Load capacity |

Horizontal |

1 |

1 |

kg |

|

Vertical |

0.05 | 0.05 | ||

|

Inverted |

0.1 | 0.1 | ||

|

Electrical capacitance |

3.6 |

3.6 |

μF±20% |

|

|

Material |

Aluminum |

Aluminum |

|

|

|

Mass |

200 |

200 |

g±5% |

|

Note: Max driving voltage could be -20V~150V, Recommended voltage 0~120V for long-term operation to extend lifetime. Technical data are measured by CoreMorrow E00/E01 series piezo controller.

Technical data are measured by CoreMorrow E00/E01 series piezo controller.

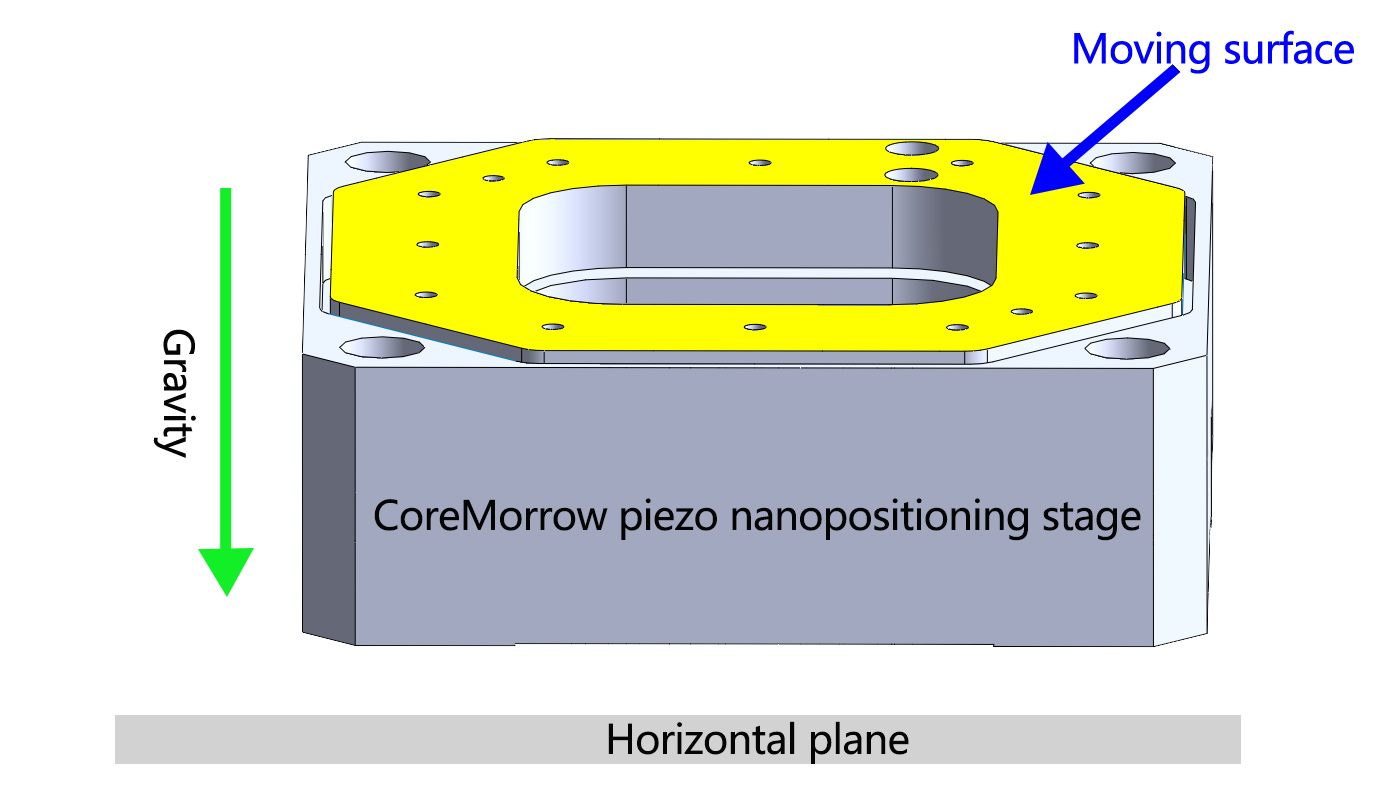

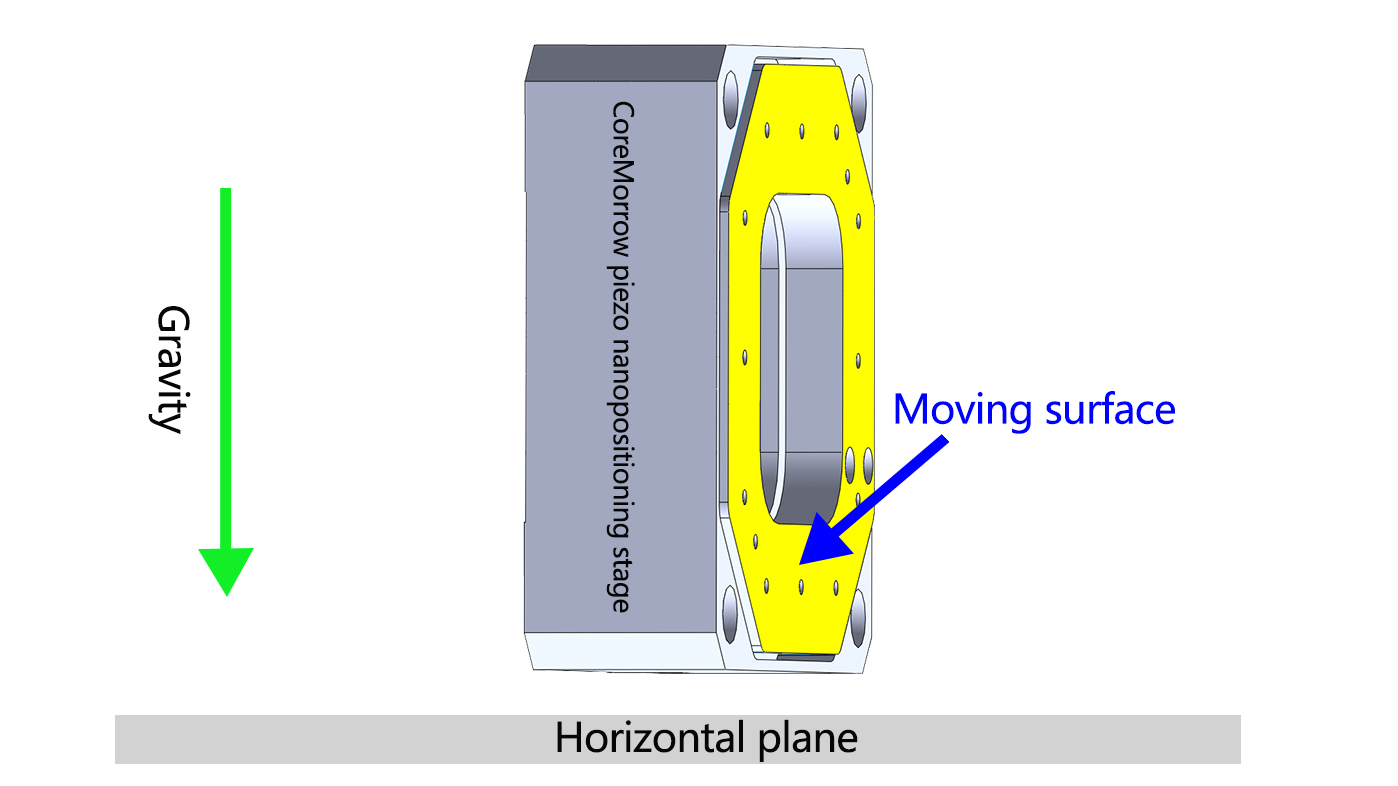

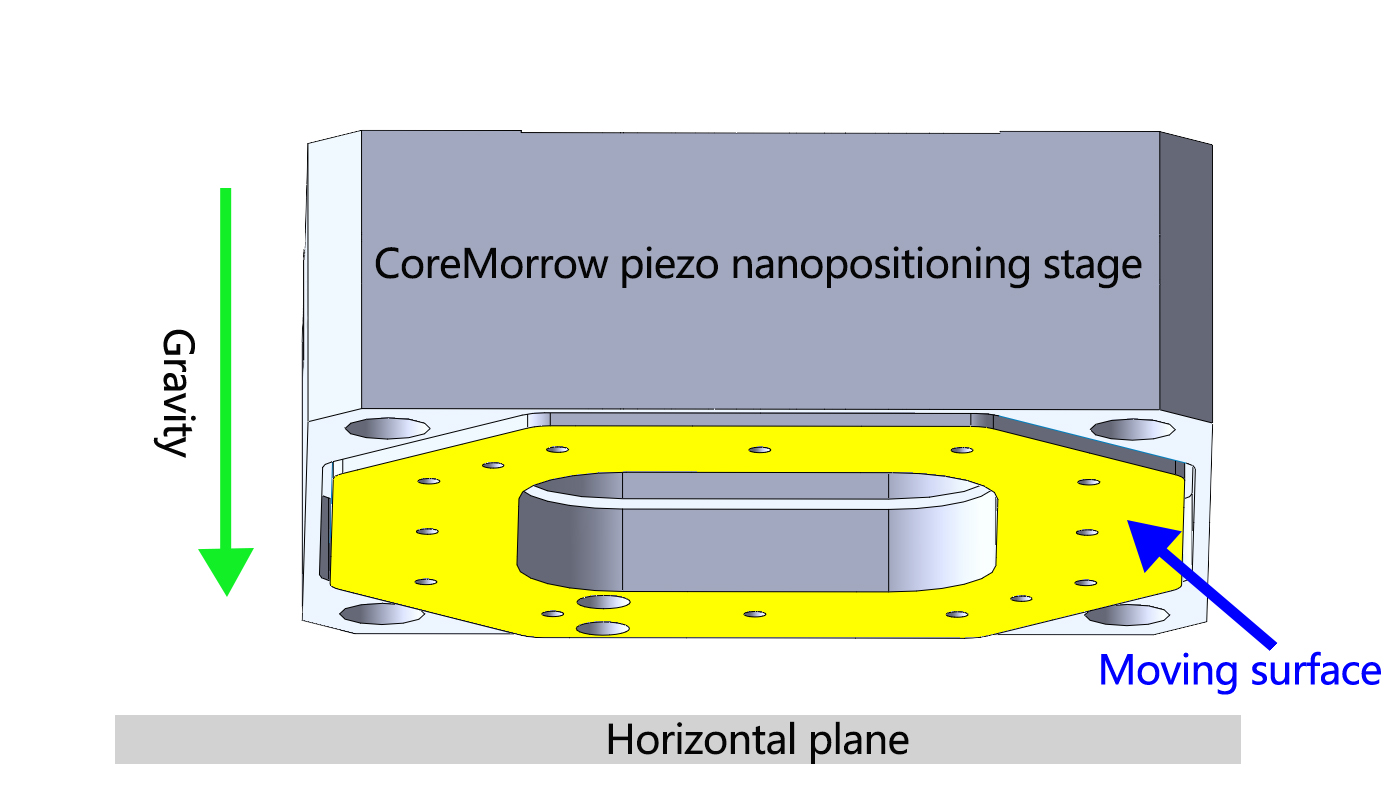

| Mounting Method |

Horizontal Mounting |

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

|

|

||||||||||||

|