- Introduction

- Controllers

- Feedback

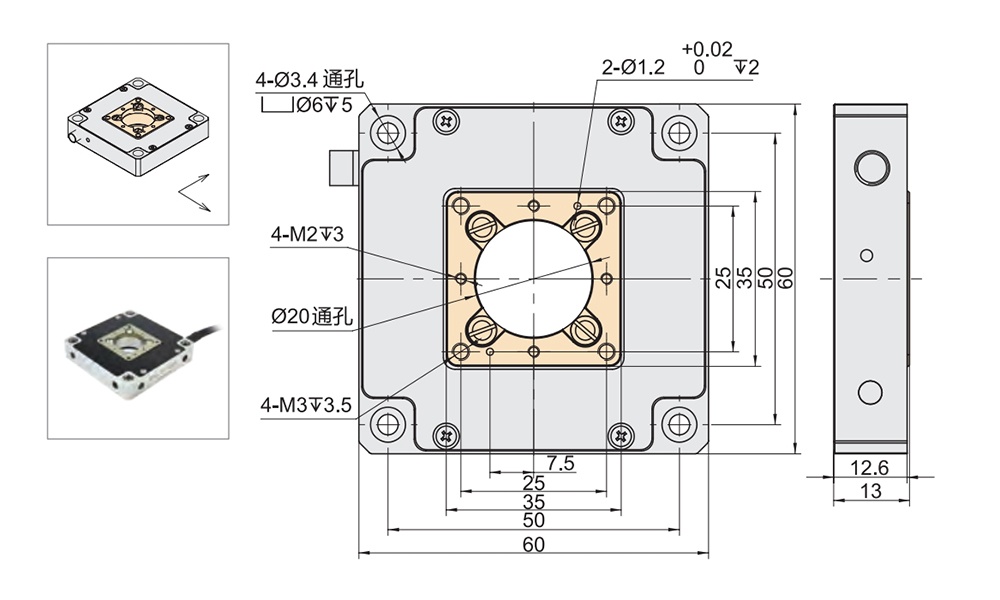

P16.XY100 series piezoelectric scanner is an XY-axis translation scanning platform adopting amplifying mechanism. The center through-hole aperture is 20mm. The series of scanners are available in ±50μm travels, and the open-loop/closed loop is optional.

Characteristics

|

|

|

|

|

|

|

|

|

|

|

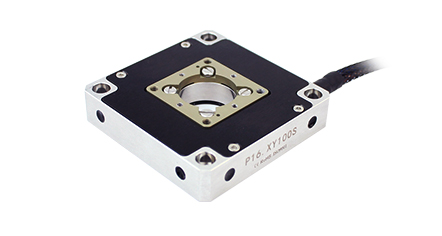

Appearance

|

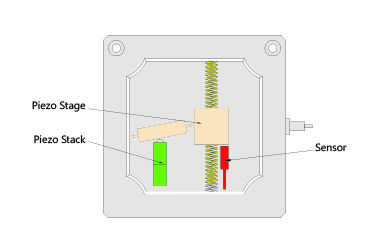

Moving-part

|

Amplified-driving

|

|

High Stiffness Large Load Capacity

P16.XY100 piezo scanner adopts principle of mechanism amplification design and built-in high-performance piezo ceramic. It can realize travel of ±50μm. The integrated structure design has no coupling of XY axis motion. |

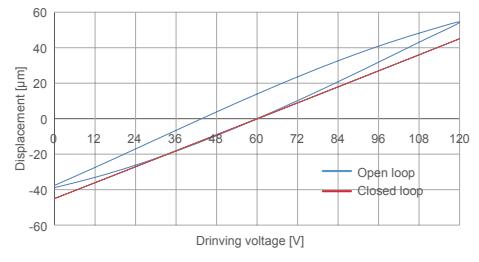

P16.XY100 Curve

|

Application Cases-XY Adjustment P16.XY piezo scanner is used in optical path adjustment experiment with its large load and high frequency. P16 carrying mirror frame to move precisely in XY axis.

|

Applications

|

|

|

|

|

|

|

|

|

|

| Technical data | ||||

|

Models |

S-Closed loop |

P16.XY100S |

P16.XY100K |

Units |

|

Active axis |

X、Y |

X、Y |

|

|

|

Driving channels |

3 driving channels |

3 driving channels 2 sensing channels |

|

|

|

Travel range |

±33/axis(0~100V) |

±40/axis(0~120V) |

μm±10% |

|

|

Max.travel range |

±40/axis(0~120V) |

±50/axis(0~150V) |

μm±10% |

|

|

Sensor type |

SGS/ |

- |

|

|

|

Aperture size |

Ø20 |

Ø20 |

mm |

|

|

Resolution |

2.5 |

1 |

nm |

|

|

Linearity |

1 |

- |

%F.S |

|

|

Repeatability |

0.5 |

- |

%F.S |

|

|

Pitch/yaw/roll |

<25 |

<25 |

μrad |

|

|

Push/pull force |

30/30 |

30/30 |

N |

|

|

Stiffness in motion direction |

0.5 |

0.5 |

N/μm±20% |

|

|

Unloaded resonant frequency |

600 |

600 |

Hz±20% |

|

|

Unloaded step time |

10 |

1.6 |

ms±20% |

|

|

Load capacity |

Horizontal |

1.5 |

1.5 |

kg |

|

Vertical |

0.4 | 0.4 | ||

|

Inverted |

1.5 | 1.5 | ||

|

El.capacitance |

3.6/axis |

3.6/axis |

μF±20% |

|

|

Material |

Steel, Al |

Steel, Al |

|

|

|

Mass |

220 |

220 |

g±5% |

|

Note: Above parameters are measured with the E00/E01 series piezo controller. The maximum driving voltage can be -20V~150V; for high reliability long-term use, the recommended driving voltage is 0~120V.

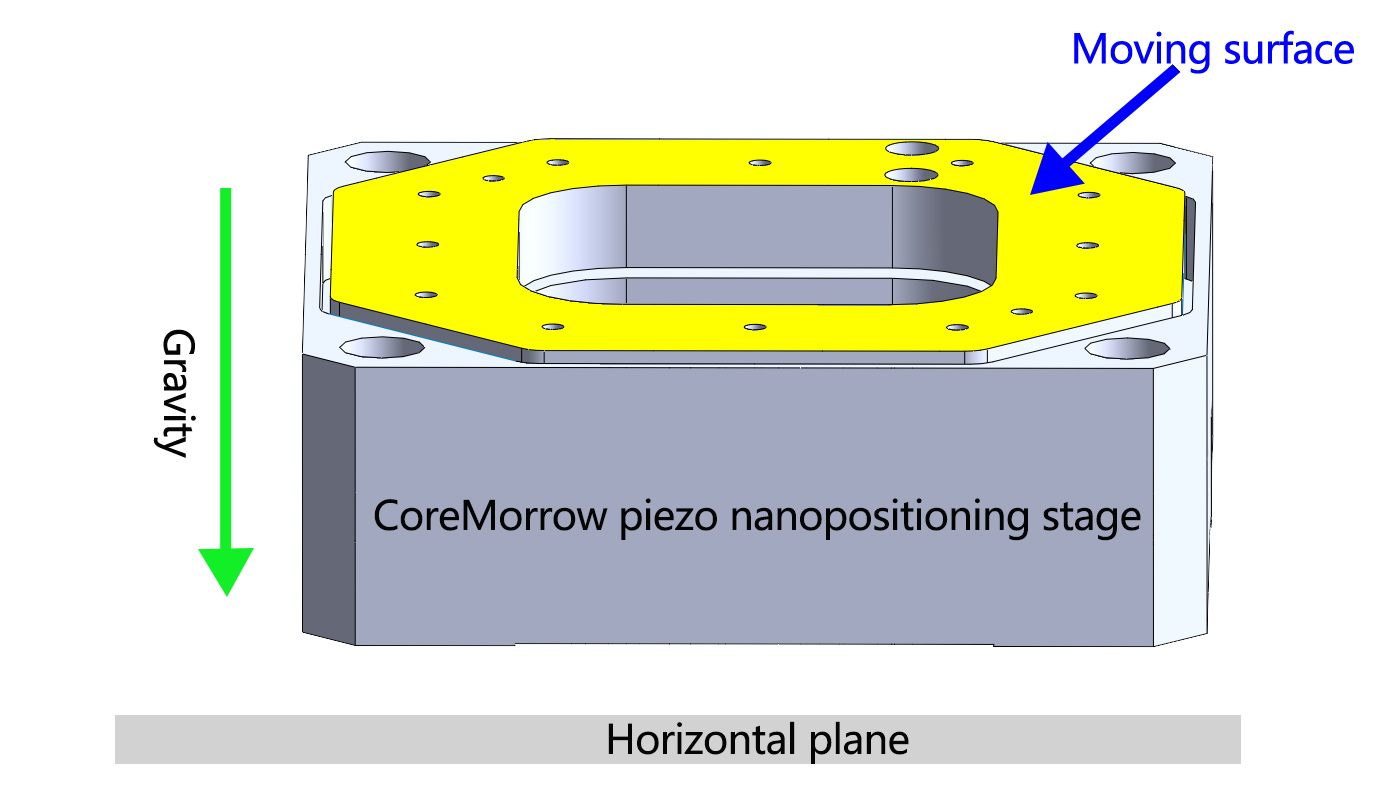

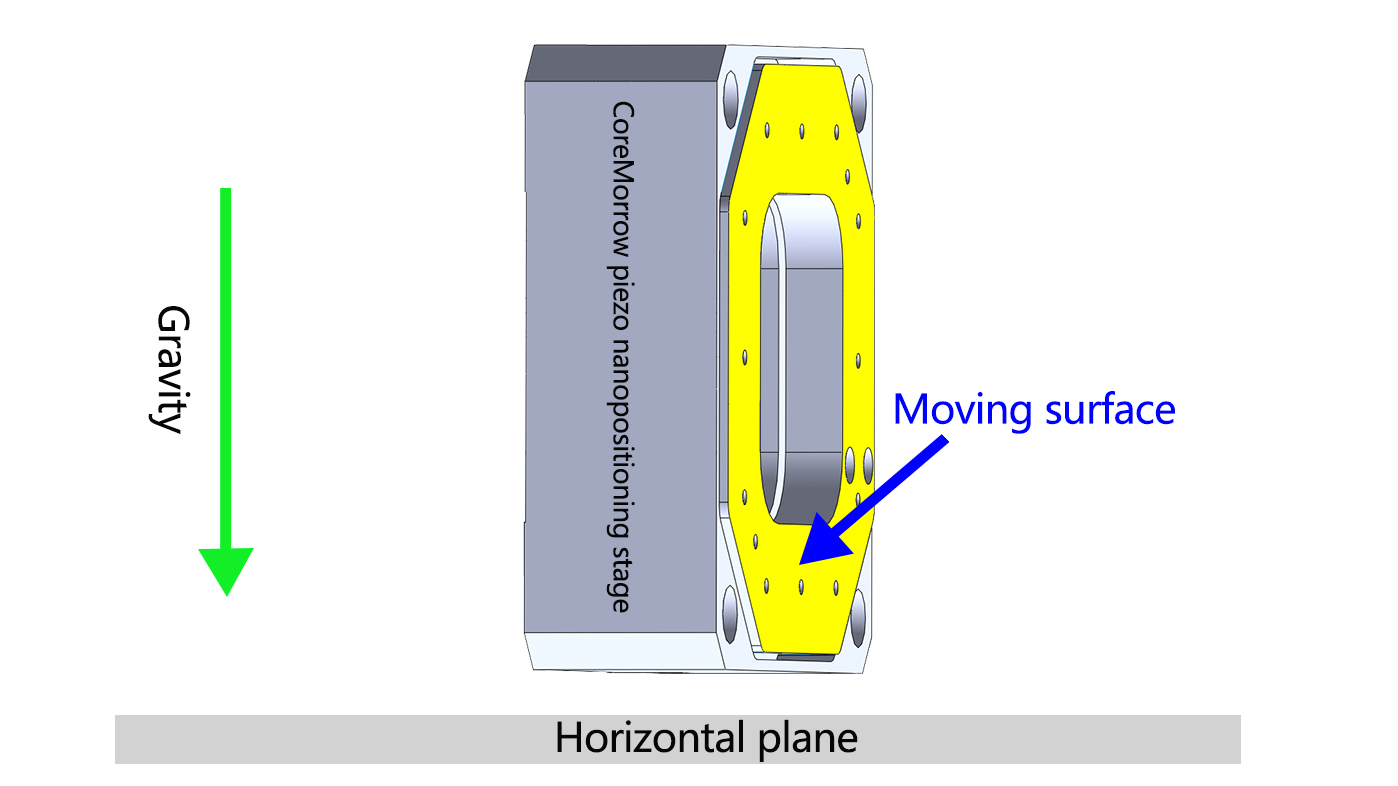

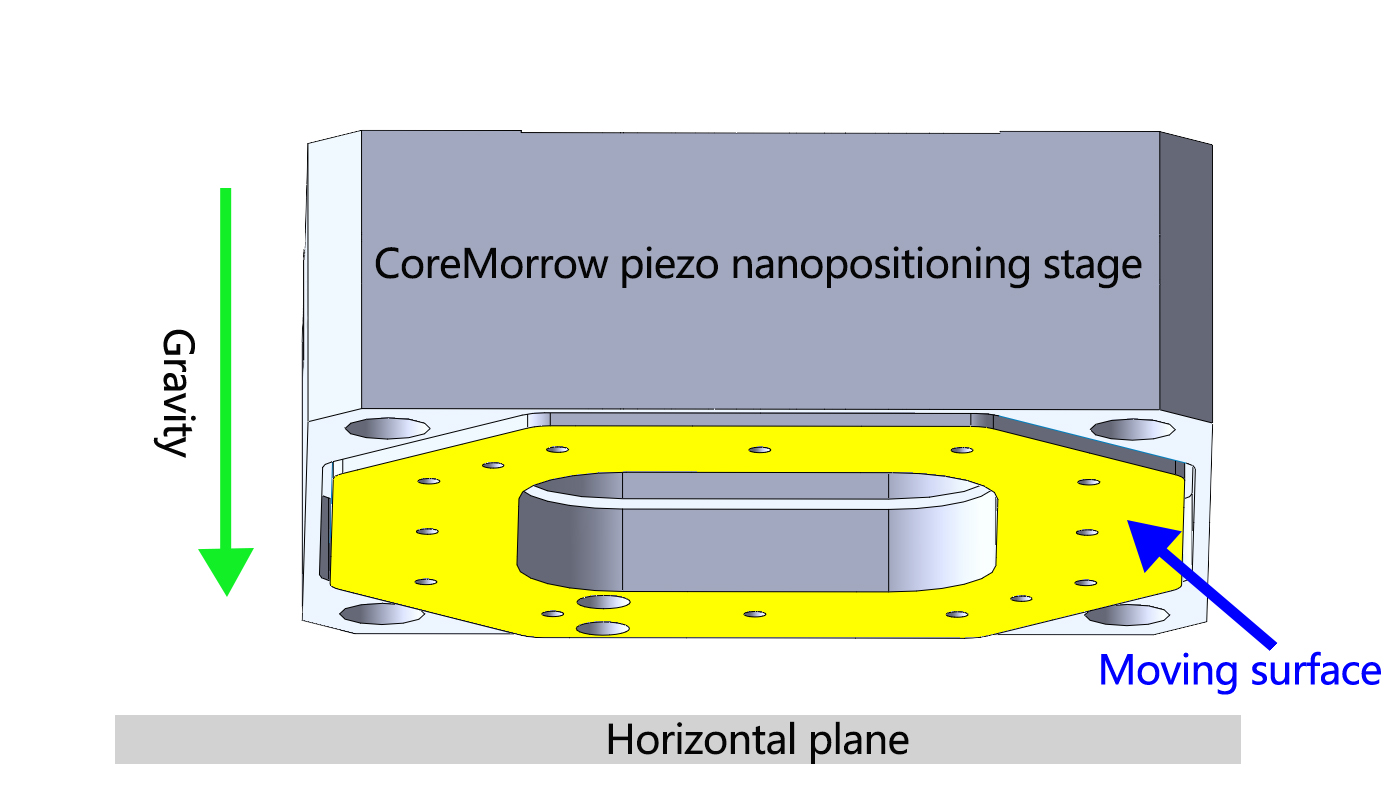

| Mounting Method |

Horizontal Mounting |

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

|

|

|||||||||||||||||

|