- Introduction

- Controllers

- Feedback

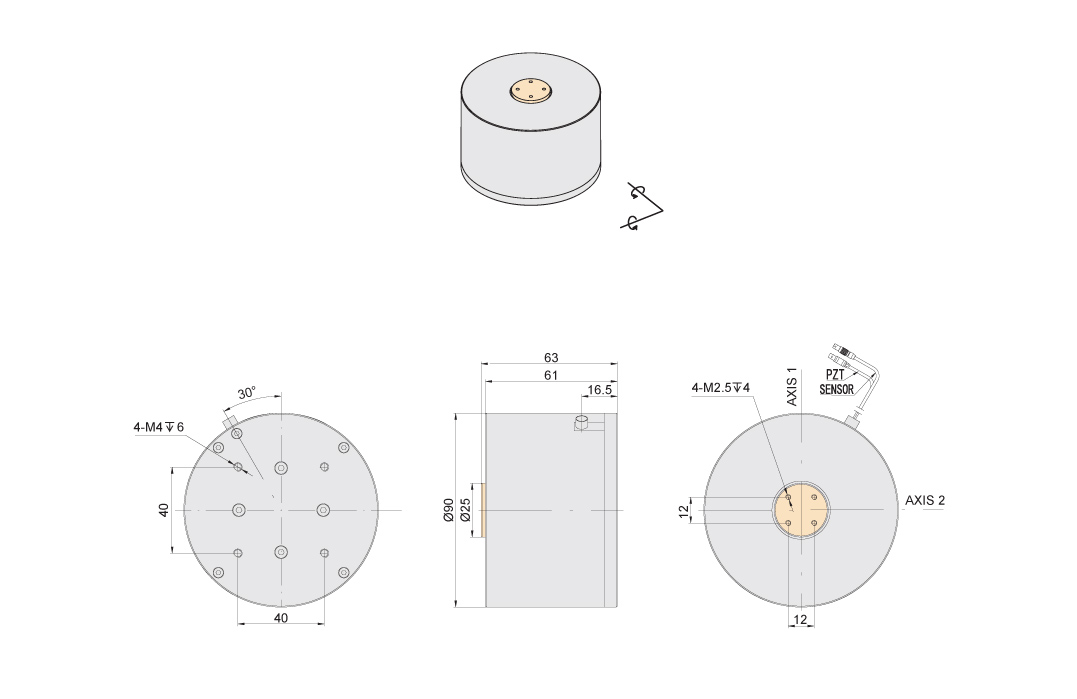

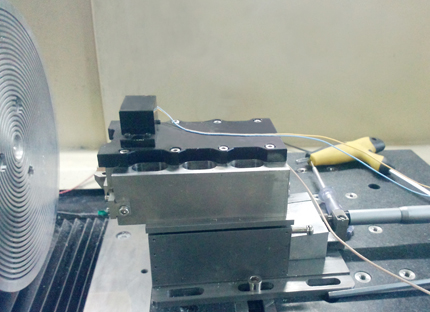

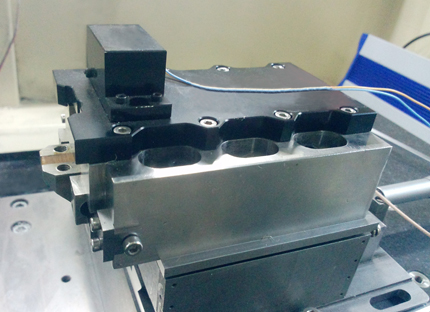

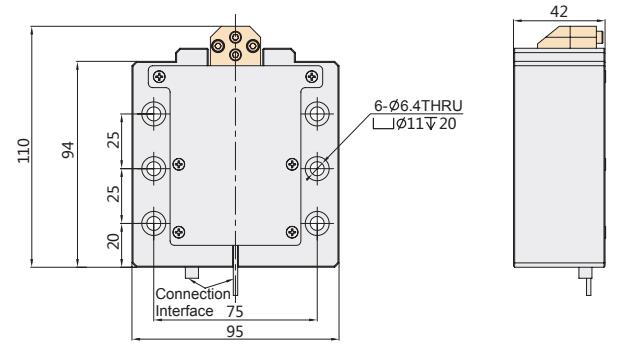

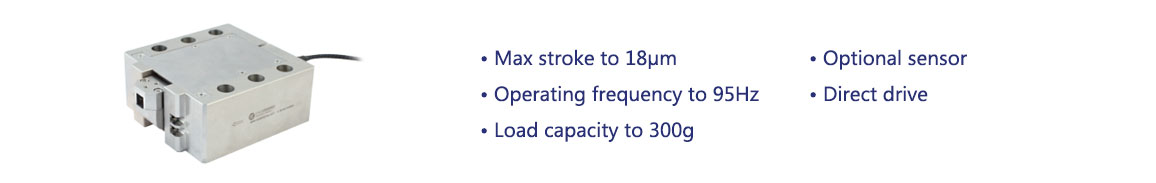

P92.X20S/K fast tool positioning stage is a fast tool microfeed stage designed for ultra-precision turning. It adopts direct-driving structure, features large load capacity, high frequency, and optional capacitive sensor with nano-scale positioning accuracy

Characteristics

|

|

|

|

|

|

|

|

|

Applications

|

|

|

|

|

|

|

|

|

|

| Technical Data | ||||

|

Type |

P92.X20S |

P92.X20K |

Units |

|

|

Active axes |

X | X |

|

|

|

Drive control |

1 driving channel 1 sensing channel |

1 driving channel |

|

|

|

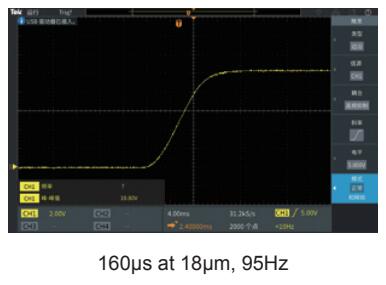

Travel range |

18@95Hz (0~150V) |

18@95Hz (0~150V) |

μm±10% |

|

|

9@190Hz |

9@190Hz |

|||

|

1@600Hz |

1@600Hz |

|||

|

Sensor |

SGS |

- |

|

|

|

Resolution |

0.5 |

0.2 |

nm |

|

|

Linearity |

0.1 |

- |

%F.S. |

|

|

Repeatability |

15 |

- |

nm |

|

|

Load capacity |

Horizontal |

0.3 |

0.3 |

kg |

|

Vertical |

0.5 | 0.5 | ||

|

Inverted |

0.3 | 0.3 | ||

|

Stiffness |

120 |

120 |

N/μm ±20% |

|

|

Unloaded resonant frequency |

4000 |

4000 |

Hz±20% |

|

|

Size |

L110 x W95 x H42 |

L110 x W95 x H42 |

mm |

|

|

Mass |

2100 |

2100 |

g±5% |

|

|

Operating temperature |

-20~80 |

-20~80 |

℃ |

|

|

Cable length |

|

1.5m or longer |

1.5m or longer |

m±10mm |

Note: Above parameters are measured with the E00/E01 series piezo controller. The maximum driving voltage can be -20V~150V; for high reliability long-term use, the recommended driving voltage is 0~120V.

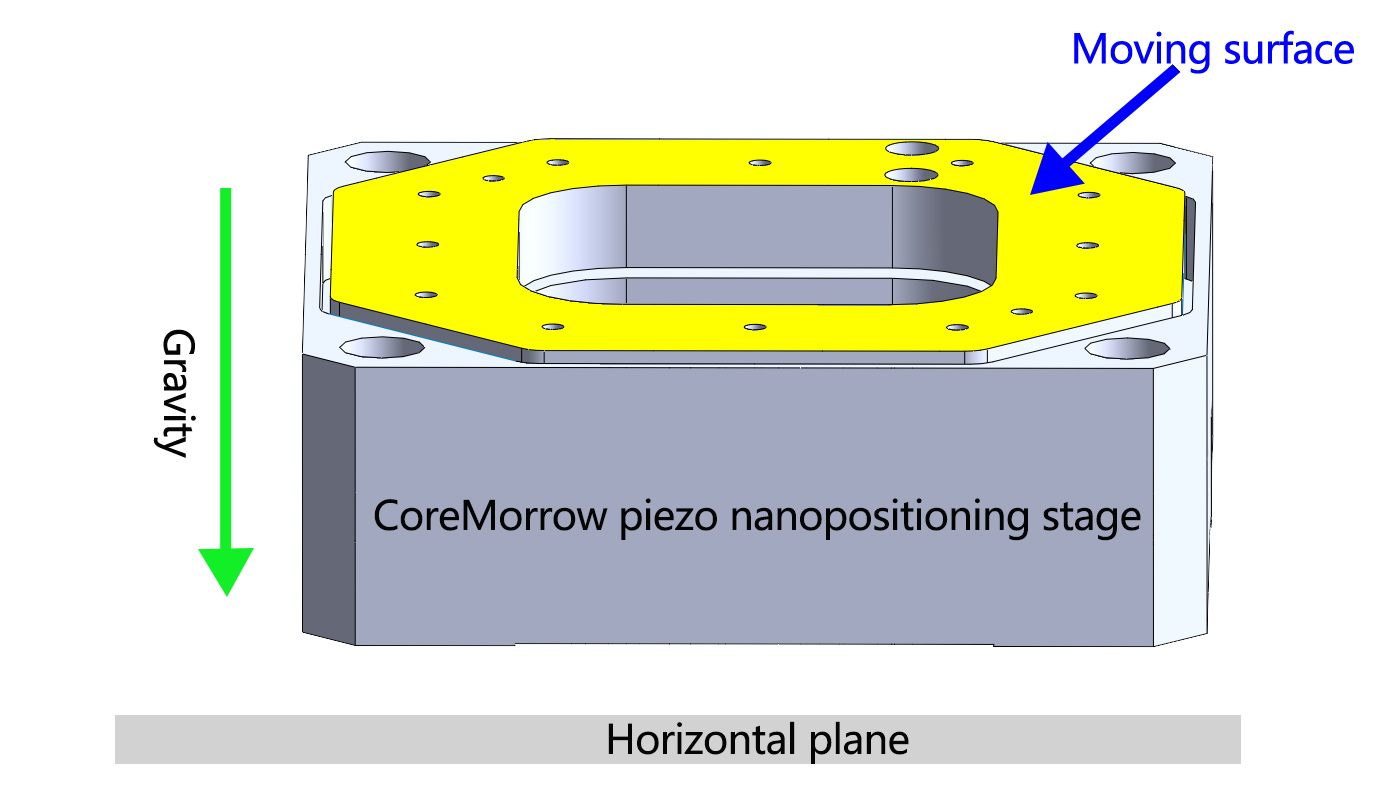

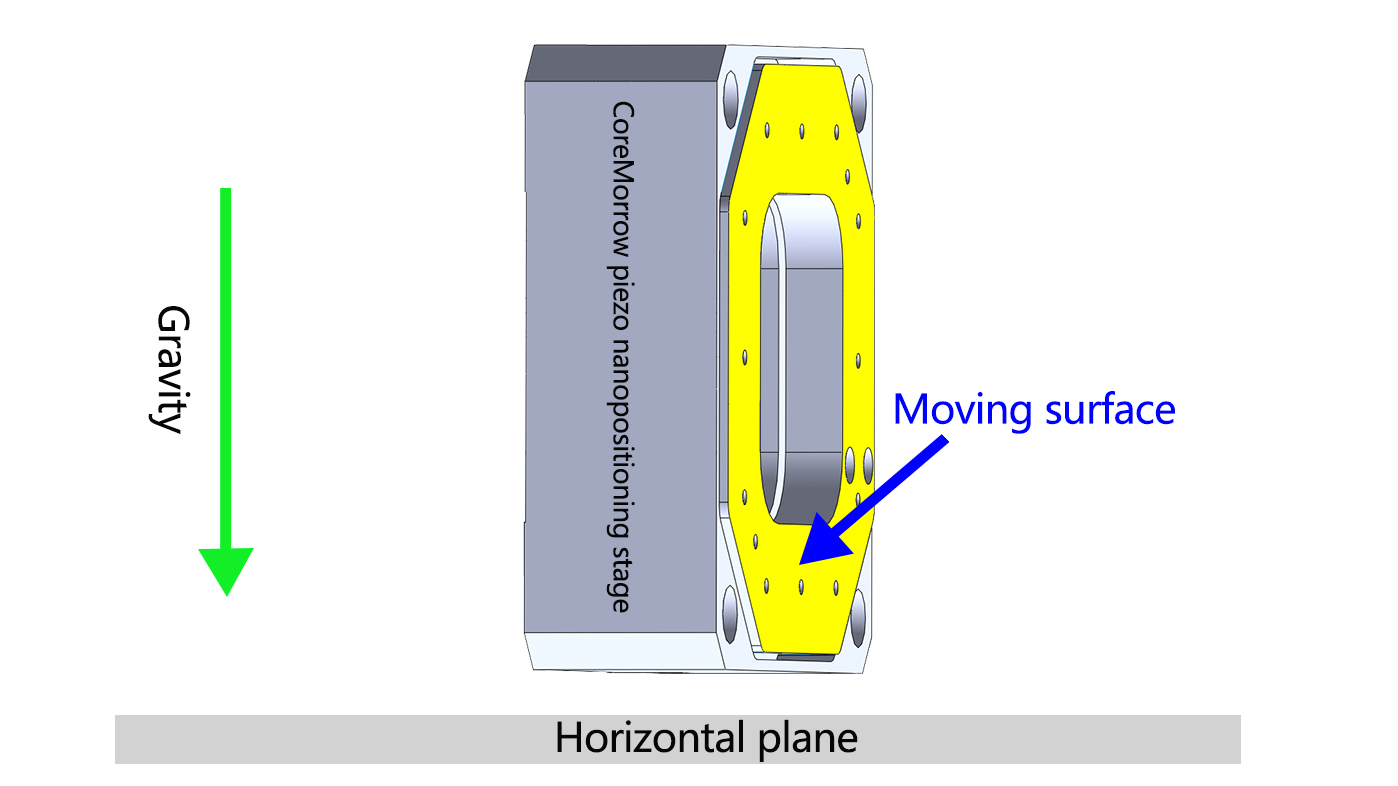

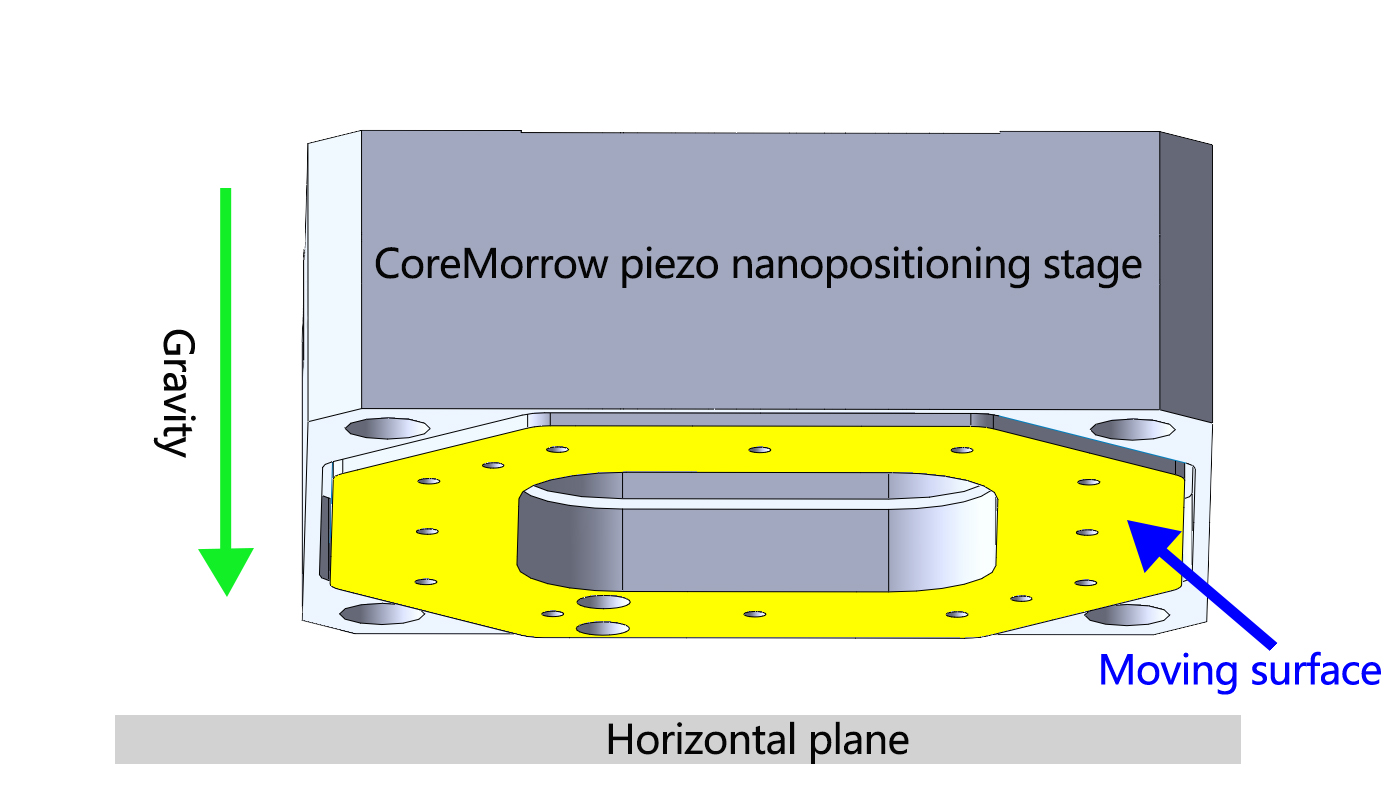

| Mounting Method |

Horizontal Mounting |

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

Recommended Controller

|

|

|

|

|

||||||||||||

|