- Introduction

- Controllers

- Feedback

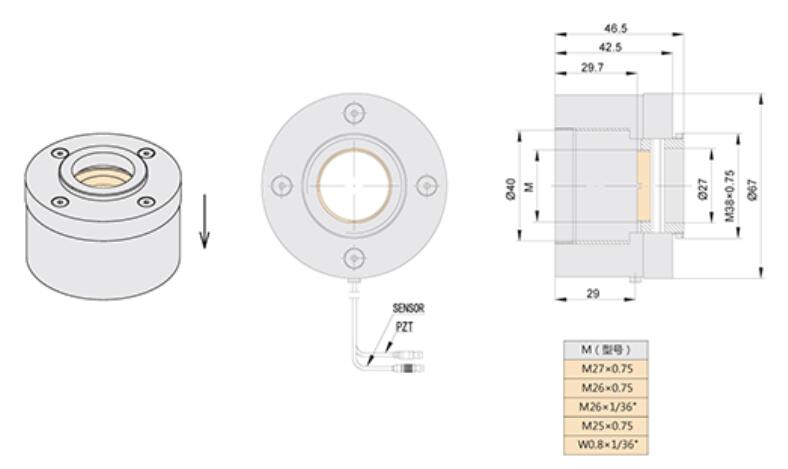

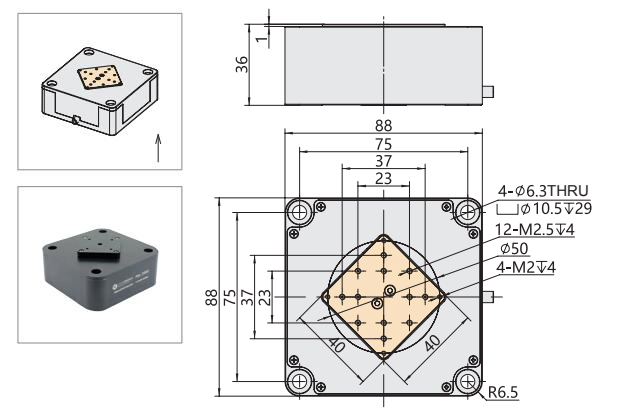

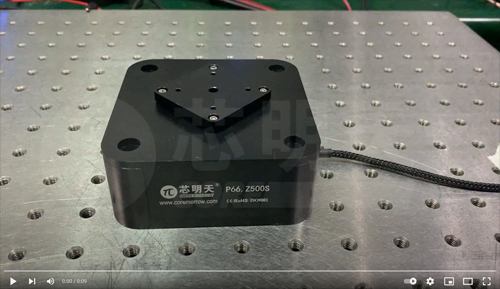

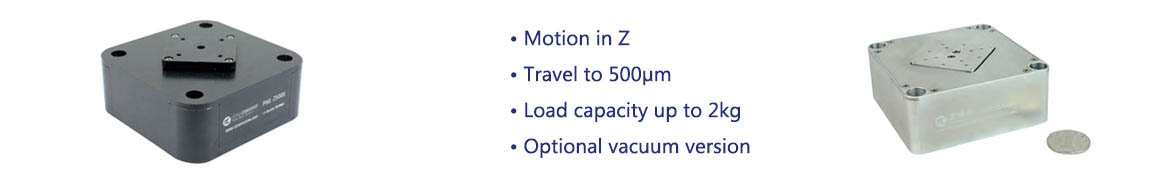

P60.Z500 is Z-direction motion piezoelectric positioning stage. It adopts the design principle of piezoelectric ceramic amplifying mechanism. It has the characteristics of small volume, no friction, and fast response speed. It is equipped with high-precision sensors. To achieve nano-level resolution and positioning accuracy with high reliability, the voltage level shift stage plays an important role in the field of precision positioning.

Characteristics

|

|

|

|

|

| Technical data | |||

|

Models |

S-Closed loop K-Open loop |

P60.Z500S P60.Z500K |

Untis |

|

Active axes |

Z |

|

|

|

Drive control |

1 driving channel 1 sensing channel |

|

|

|

Travel range(0~120V) |

400 |

μm±20% |

|

|

Max.travel range(0~150V) |

500 |

μm±20% |

|

|

Integrated sensor |

SGS/- |

|

|

|

Closed/open loop resolution |

13.5/0.5 |

nm |

|

|

Closed-loop linearity |

0.1/- |

%F.S. |

|

|

Repeatability |

0.05/- |

%F.S. |

|

|

Unloaded resonant frequency |

0.29 |

kHz±20% |

|

|

Load capacity |

Horizontal |

2 |

kg |

|

Vertical |

0.03 | ||

|

Inverted |

0.07 | ||

|

Electrical capacitance |

28.8 |

μF±20% |

|

|

Material |

Steel, Aluminum |

|

|

|

Mass |

650 |

g±5% |

|

Note: Max driving voltage could be -20V~150V, Recommended voltage 0~120V for long-term operation to extend lifetime.

Technical data are measured by CoreMorrow E00/E01 series piezo controller.

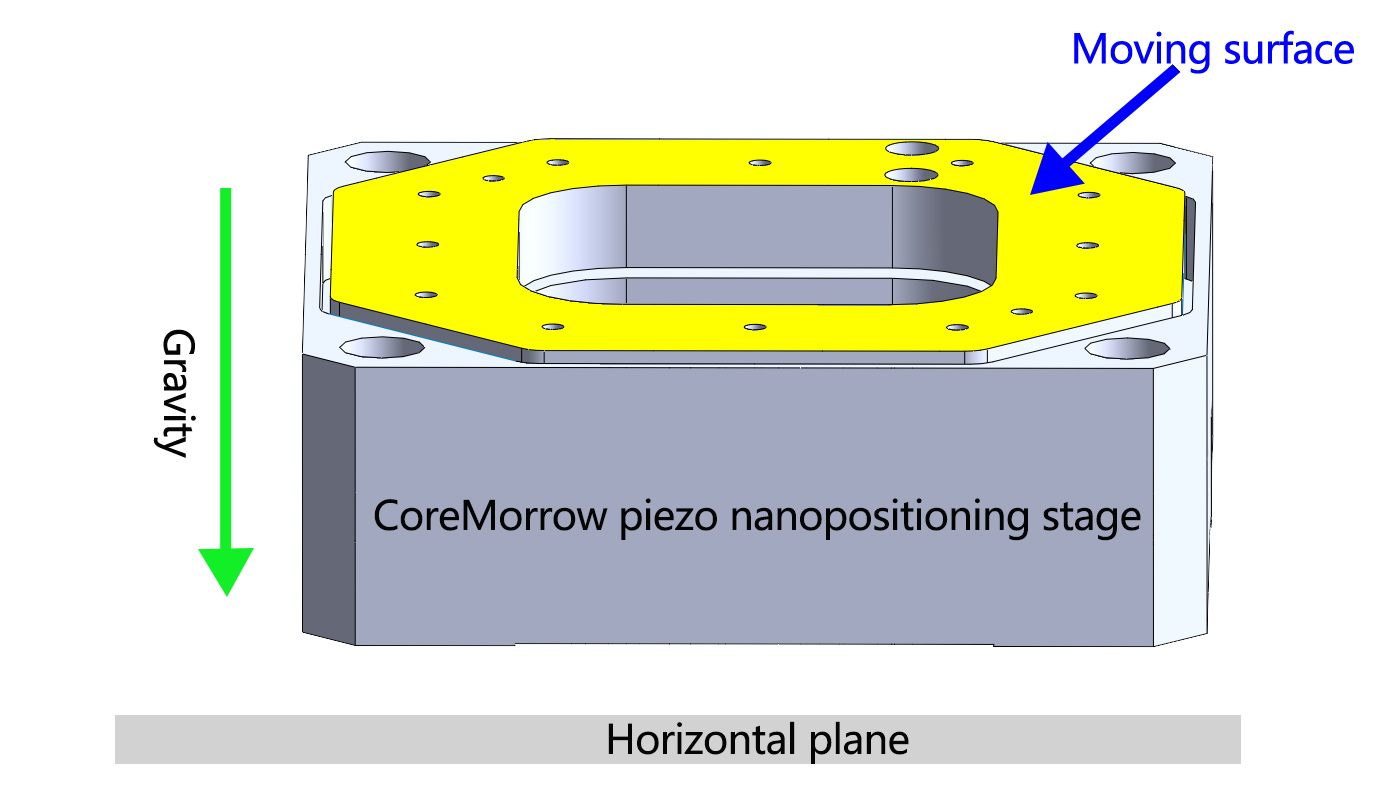

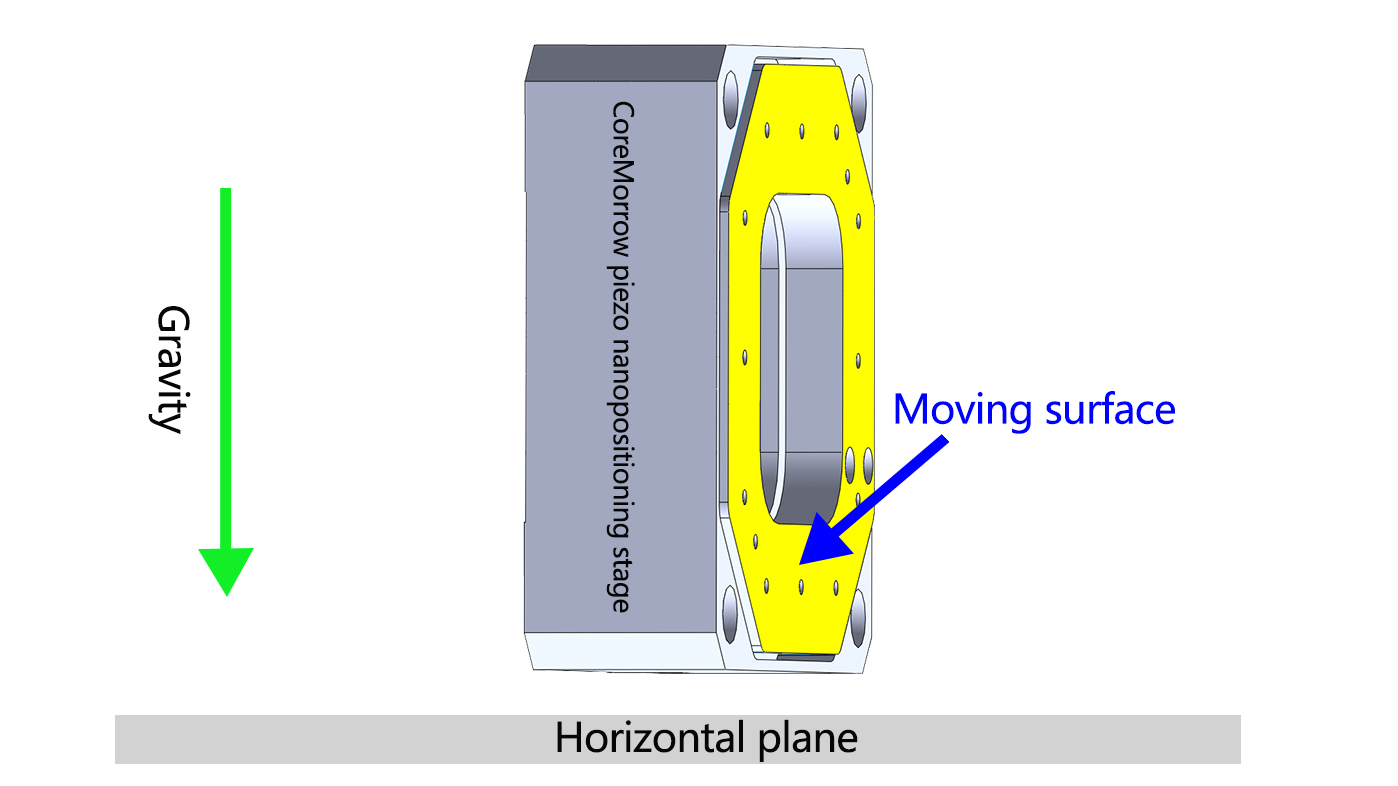

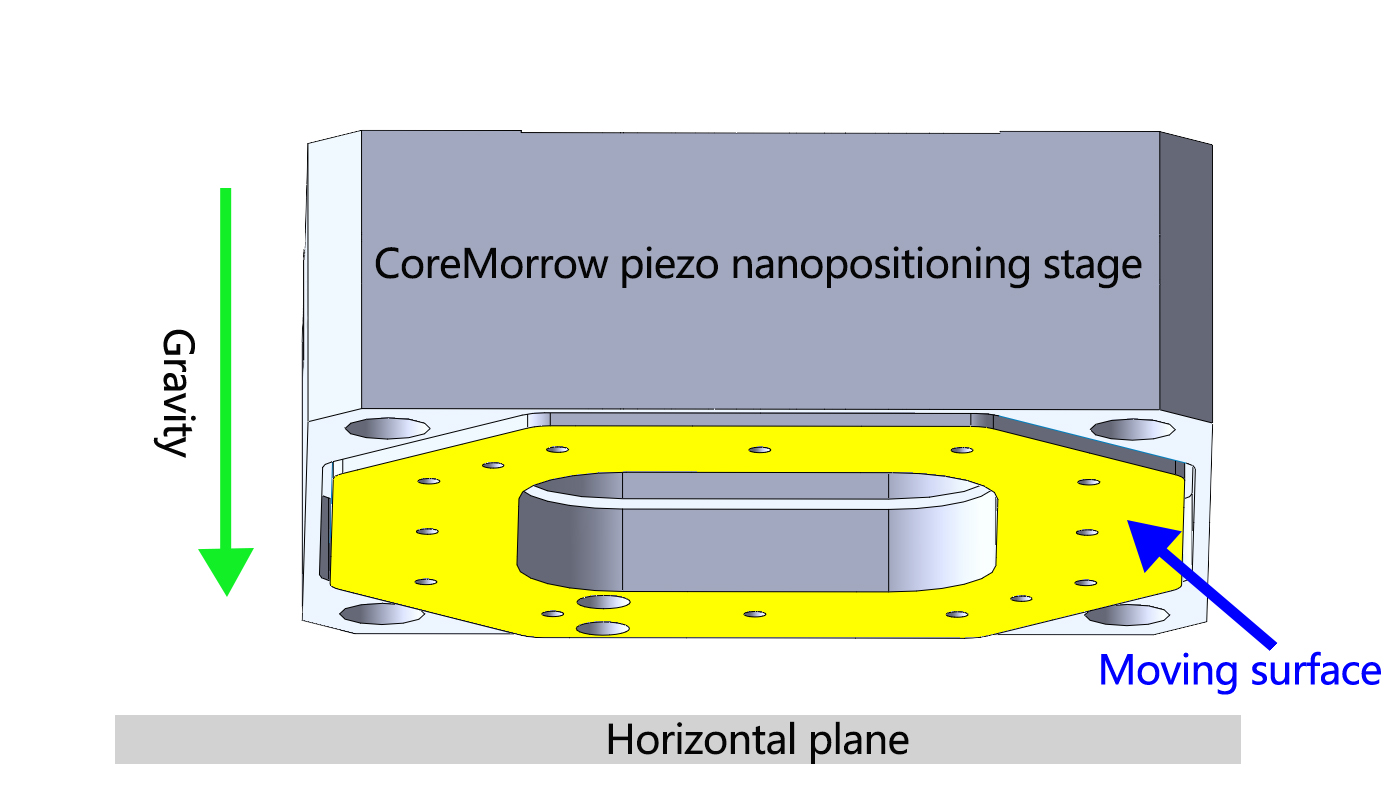

| Mounting Method |

Horizontal Mounting |

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

|

|

||||||||||||

|

|