- Introduction

- Controllers

- Feedback

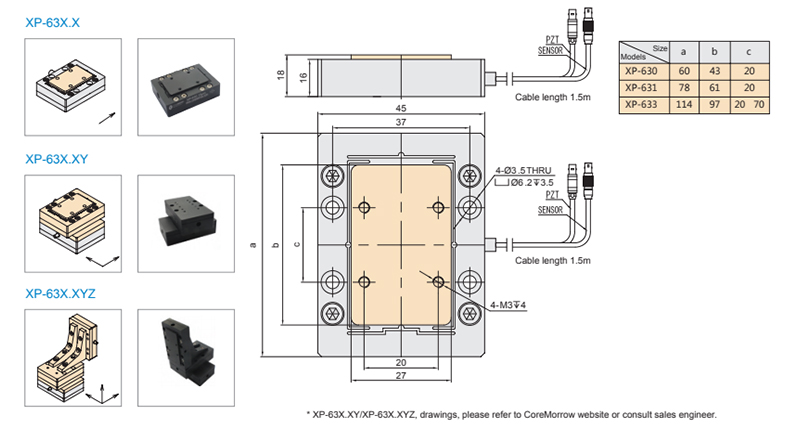

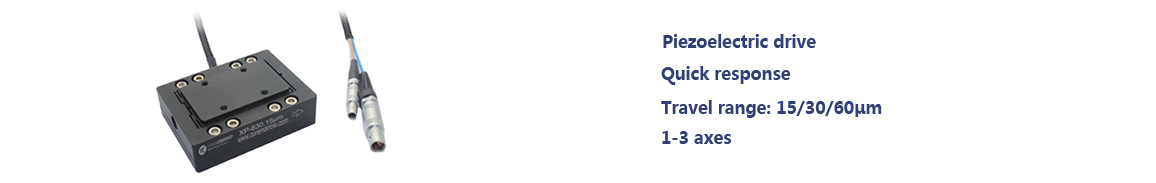

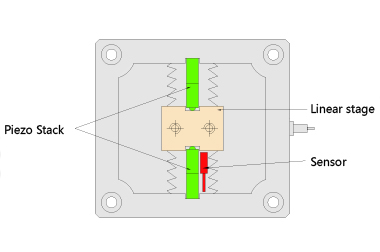

XP-63X piezo nanopositioning stage adopts frictionless flexible hinge guiding mechanism and has the characteristics of high rigidity, high resolution and fast response time. XY, XYZ versions could be available through adapter.

Characteristics

|

|

|

|

|

|

|

|

|

|

|

Appearance

|

Moving-part

|

Direct-driving

|

|

1~3 axes

Two or three XP-63X could be connected through the adapter to form a variety of motion structures of XY, XZ and XYZ. |

Small Size, Large Stiffness The structure of XP-63X has the characteristics of large stiffness, large load capacity and higher unload resonant frequency. It also has high operating frequency with load and the response time could be up to sub-milliseconds. When XP-630 drives 20g load with response time of 5ms. The dimension of XP-630 is only 60×45×18mm, making it easy to integrate with other stage devices. |

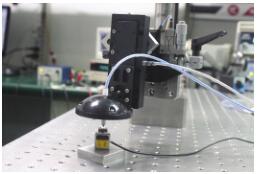

Application Cases XP-633 is used to drive the probe for precise displacement control, and the displacement and force are calibrated. The resolution of the force could reach 0.3mN.

|

Applications

|

|

|

|

|

| Technical data | |||||

|

Models |

S-Closed loop K-Open loop |

XP-630.XS XP-630.XK |

XP-631.XS XP-631.XK |

XP-633.XS XP-633.XK |

Units |

|

Active axes |

X |

X |

X |

|

|

|

Travel range(0~120V) |

12 |

24 |

48 |

μm±10% |

|

|

Travel range(0~150V) |

15 |

30 |

60 |

μm±10% |

|

|

Integrated sensor |

SGS/- |

SGS/- |

SGS/- |

|

|

|

Closed/open loop resolution |

0.5/0.1 |

1/0.2 |

2/0.3 |

nm |

|

|

Closed-loop linearity |

0.1/- |

0.15/- |

0.15/- |

%F.S. |

|

|

Repeatability |

0.05/- |

0.05/- |

0.1/- |

%F.S. |

|

|

Pitch/Yaw/Roll |

<20 |

<25 |

<30 |

µrad |

|

|

Push/pull force capacity |

480/80 |

480/80 |

480/80 |

N |

|

|

Stiffness |

40 |

20 |

10 |

N/μm±20% |

|

|

Unloaded resonant frequency |

3.2 |

2.4 |

1.5 |

kHz±20% |

|

|

Closed/open-loop unloaded Step time |

1.5/0.8 |

3/1.6 |

5/3.2 |

ms±20% |

|

|

Load capacity |

5 |

5 |

5 |

kg |

|

|

Electrical capacitance |

1.8 |

3.6 |

7.2 |

μF±20% |

|

|

Material |

Aluminum |

Aluminum |

Aluminum |

|

|

|

Mass |

150 |

250 |

450 |

g±5% |

|

Note: Max driving voltage could be -20V~150V, Recommended voltage 0~120V for long-term operation to extend lifetime.

Technical data are measured by CoreMorrow E00/E01 series piezo controller.

|

|

||||||||||||||||||||||