How CoreMorrow Piezo Scanner Unlock Nano-world for Super-resolution Microscopy

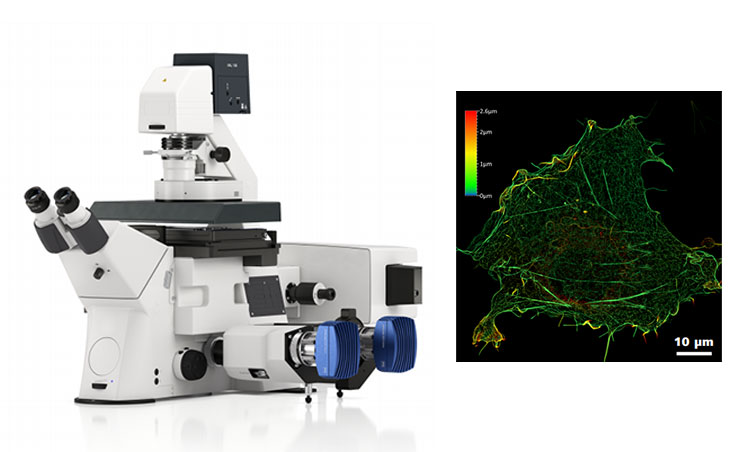

In the journey of human exploration of the microscopic world, microscopic technology, as a core demand, is constantly breaking through its limits. From life sciences, materials research, quantum technology to semiconductor manufacturing, microscopes are undergoing a revolutionary leap from "seeing" to "seeing precisely". Super-resolution microscopic imaging systems, with their ability to break through the limits of optical diffraction, can uncover the mysteries of cells in all dimensions. High-definition observation of living cells, in particular, requires dynamic regulation down to the nanometer level. The piezoelectric objective scanner is precisely the core engine that supports this demand.

(Note: Image from online resources)

I. Super-Resolution Microscope

Break through Tradition and Move from Blur to Clarity

Microscopic technology, as a core tool for scientific discovery, medical research and industrial innovation, is of great significance in the following aspects: breaking through the limits of human perception, revealing the microscopic world invisible to the naked eye, and promoting the progress of basic science; Solving problems in the minute details, failure analysis from the cellular fluoroscopy required for disease diagnosis to material surface features, and providing detailed and comprehensive evidence; The continuous innovation of driving technology, with cutting-edge fields such as gene editing, nanotechnology, and semiconductor chips all relying on the support of microscopic technology.

(Note: Image from online resources)

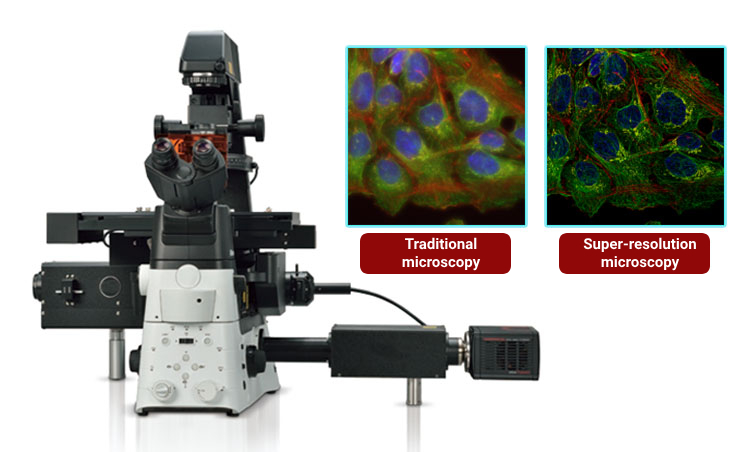

Super-Resolution Microscopy

Super-Resolution Microscopy (SRM) is a significant breakthrough in the field of optical microscopy in recent years. It has broken through the diffraction limit of traditional optical microscopy, enabling higher resolution and the observation of smaller structures, such as: In the field of biomedicine, super-resolution microscopic imaging technology is generally used to observe biological samples with resolutions far exceeding those of traditional optical microscopes. By using special fluorescence labeling, pulse excitation or image localization algorithms, its resolution can reach the nanometer level, thereby revealing the internal structure and dynamic process details of cells.

(Note: Image from online resources)

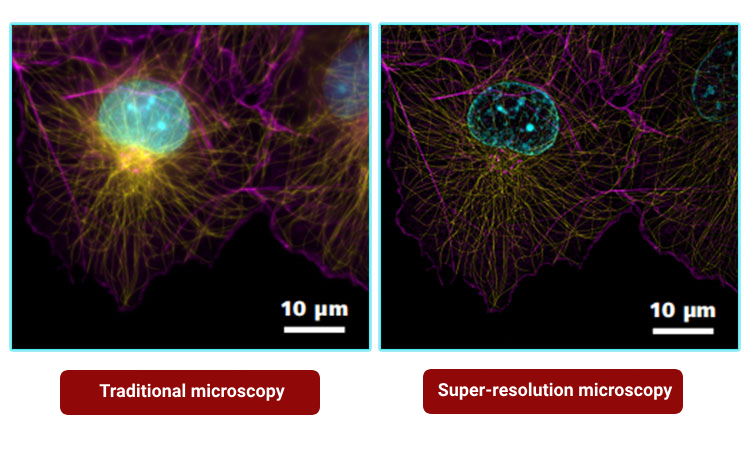

When using traditional microscopes for live cell imaging, it is often interfered by non-focal plane blurring signals and background signals, resulting in a decrease in image contrast and resolution. The super-resolution microscope uses structured light illumination, which can perform optical section imaging on large-volume samples and has clear contrast and high resolution in all dimensions. While providing illumination, it is necessary to quickly capture the fluorescence signals from different focal planes and then merge them into a clear image. At this point, the rapid response and precise positioning capabilities of the piezoelectric objective lens locator are relied upon.

(Note: Image from online resources)

II. CoreMorrow Piezoelectric Nano-Positioning Technology

The core requirements of super-resolution imaging are nanoscale precision and ultra-fast response speed. It must not only be capable of stably controlling the precise movement of the objective lens at the nanoscale but also be able to track the dynamic changes of fluorescent molecules in real time. In the precise optical system of a super-resolution microscope, the piezoelectric objective scanner can be said to be an irreplaceable key component. This precision positioning device based on piezoelectric ceramic technology needs to minimize vibration, provide the Z-direction focusing accuracy and stability required for super-resolution imaging, and help super-resolution microscopes achieve nanometer-level precision.

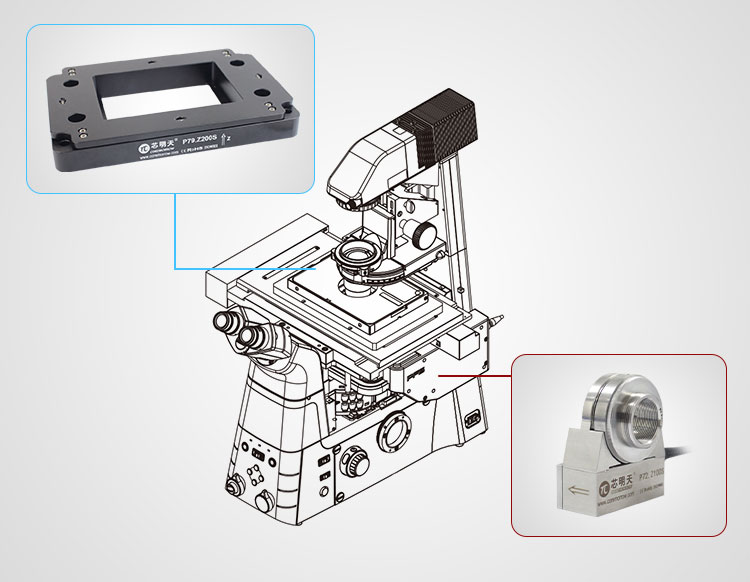

(The installation position diagram and the microscope model diagram are from online resources)

CoreMorrow piezoelectric objective scanner adopts a closed-loop feedback system, featuring high positioning accuracy and a response speed dozens of times faster than that of traditional mechanical structures. It can complete focusing within milliseconds and promptly capture the instantaneous state of molecular movement.

Core technological advantages

Nanometer-level precision:The closed-loop positioning accuracy is extremely high, meeting the requirements of super-resolution imaging.

Millisecond-level response:

High load capacity::It has a high no-load resonant frequency and can perform high-speed and precise movements under high loads.

Focusing stability:The flexible hinge parallel guiding mechanism design ensures no friction, with a small objective lens compensation amount, and features extremely high focusing stability.

P72 Piezo Objective Scanner

P72 piezoelectric objective scanner is a Z-axis motion piezo positioner specially designed for objective lens focusing microscopy. The objective positioner is loaded with a microscopic detection/measurement or observation device to improve accuracy. It can be equipped with a load lens for precise positioning adjustment to improve focusing accuracy and can be used in conjunction with various high-resolution microscopes.

Characteristics

• Travel to 100μm

• Load capacity to 0.4kg

• Millisecond response time

• Closed loop for high repeatability

• Open-loop and closed-loop options are available

Typical Model

|

Model |

P72.Z100S |

|---|---|

|

Active axis |

Z |

|

Drive control |

1 driving channel, 1 sensing channel |

|

Nominal travel range (0~120V) |

80µm |

|

Max. travel range(0~150V) |

100µm |

|

Sensor |

SGS |

|

Resolution |

3nm |

|

Closed-loop linearity |

0.1%F.S. |

|

Closed-loop Repeatability |

0.05%F.S. |

|

Closed-loop Repeatability |

110N/15N |

|

Stiffness |

1.4N/µm |

|

Unloaded resonant frequency |

350Hz |

|

Loaded resonant frequency |

150Hz@200g |

|

Closed-loop unloaded step time |

10ms |

|

Closed-loop operating frequency (-3dB) |

70Hz@100g |

|

Load capacity |

0.2Kg |

|

El. capacitance |

3.6μF |

|

Material |

Steel |

|

Mass |

150g |

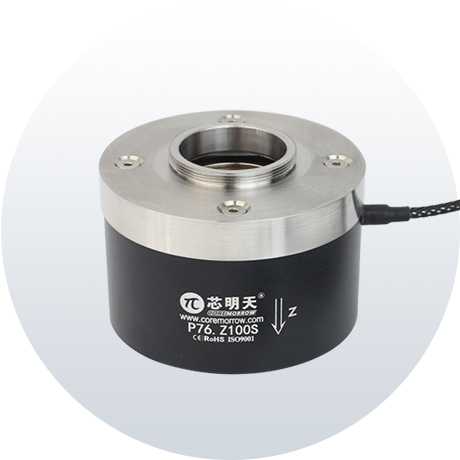

P76 Large-load Piezo Objective Scanner

P76 series piezoelectric objective scanner features a large load capacity up to 900g, Z-axis linear motion range from 40 to 200μm, adopting flexible hinge mechanism, no friction, good linearity, high closed-loop positioning accuracy.The detachable threaded adapter design makes it compatible with various models of microscopes.

Characteristics

• Travel to 200μm

• Load capacity to 900g

• Millisecond response time

• Closed loop for high repeatability

• Excellent focusing stability

Typical Model

|

Model |

P76.Z100S |

|---|---|

|

Active axis |

Z |

|

Drive control |

1 driving channel, 1 sensing channel |

|

Nominal travel range (0~120V) |

80μm |

|

Max. travel range(0~150V) |

100μm |

|

Sensor |

SGS |

|

Resolution |

1nm |

|

Closed-loop linearity |

0.03%F.S. |

|

Closed-loop Repeatability |

0.02%F.S. |

|

Push/pull force |

70N/10N |

|

Stiffness |

0.8N/μm |

|

Unloaded resonant frequency |

800Hz |

|

Closed-loop operating frequency (-3dB) |

160Hz (Unloaded) |

|

Closed-loop unloaded step time |

5ms |

|

Load capacity |

0.5kg |

|

El. capacitance |

7.2μF |

|

Material |

Steel, Al |

|

Mass |

500g |

P79 Large-load Piezoelectric Nano-positioning Platform

P79 is a 1-3 axes micro-motion platform, mainly used for supporting macro-motion XY-axes micro-scanning stages. After the macro-motion XY-axes positions the sample, P79 platform can perform fast Z-axis focus adjustments with milliseconds step time.

Characteristics

• 50 to 200μm travel for choice

• Large aperture

• Z or XYZ version

• Load capacity to 2kg

• High closed-loop repeatability

• UHV version available

Typical Model

|

Model

|

P79.Z200S86-D |

|---|---|

|

Active axis |

Z |

|

Drive control |

1 driving channel, 1 sensing channel |

|

Nominal travel range (0~120V) |

160µm |

|

Max. travel range(0~150V) |

200µm |

|

Sensor |

SGS |

|

Aperture |

86.5mm×128.5mm |

|

Closed-loop resolution |

6nm |

|

Closed-loop linearity |

0.15%F.S. |

|

Closed-loop Repeatability |

0.1%F.S. |

|

Picth/yaw/roll |

<20µrad |

|

Stiffness |

0.2N/µm |

|

Unloaded resonant frequency |

100Hz |

|

Load capacity |

1.5Kg |

|

El. capacitance |

21.6μF |

|

Working temperature |

-20°C~80°C |

|

Material |

Steel,Al |

|

Mass |

770g |

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.