E53.D2E-K Handheld Piezo Controller Brings More Convenient Operation

In today's rapid technological development, the requirements for equipment in the field of precision control are becoming increasingly strict. From scientific research laboratories to industrial production sites, in addition to the increasing demand for the control accuracy of piezo motors, the requirements for the rapidity of piezo motor operation and the portability of the equipment are also constantly rising. The control methods of traditional controllers are relatively monotonous and difficult to meet the diverse control requirements that require on-site immediate operations.

It is precisely because of the insight into these industry pain points that CoreMorrow has launched the E53.D2E-K handheld piezo controller, making the control of piezo motors more convenient. The handheld piezo controller can directly control the piezo motor in real time through the handle buttons, and at the same time meet the demands for convenience, efficiency and flexibility of piezo controllers.

Advantages of Handheld Piezoelectric Motor Controllers

I.

01

Flexible control, adaptable to various applications

E53.D2E-K handheld piezo controller can directly control the piezo motor through the handle, meeting the control requirements in on-site rapid operation and adjustment scenarios.

02

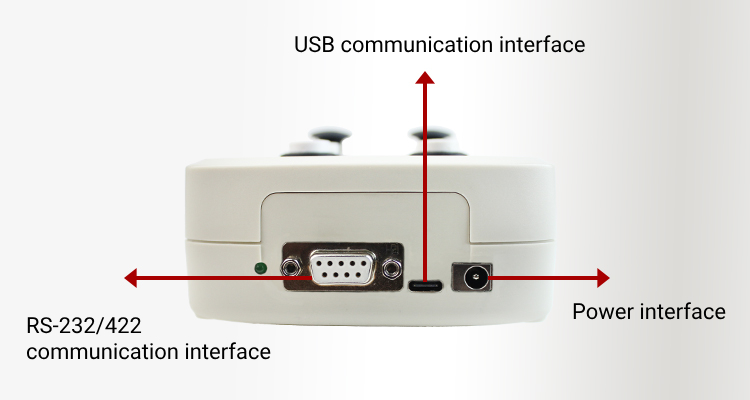

Multiple interfaces ensure smooth communication

E53.D2E-K handheld piezo controller can achieve real-time communication with the host computer through the USB interface or RS-232/422 interface, and supports secondary development of the host computer software. Its functions can be expanded according to user's own needs to ensure seamless integration of the device with other systems and stable and reliable communication.

03

Compact and portable, saving space costs

The E53.D2E-K handheld piezoelectric motor controller adopts a compact integrated design, with dimensions of only 134×58×248mm³. Compared with some large controllers, it is easy to carry.

Whether it is the limited space on the laboratory bench or the situation where mobile operations are required, it can be flexibly placed, greatly saving space costs.

04

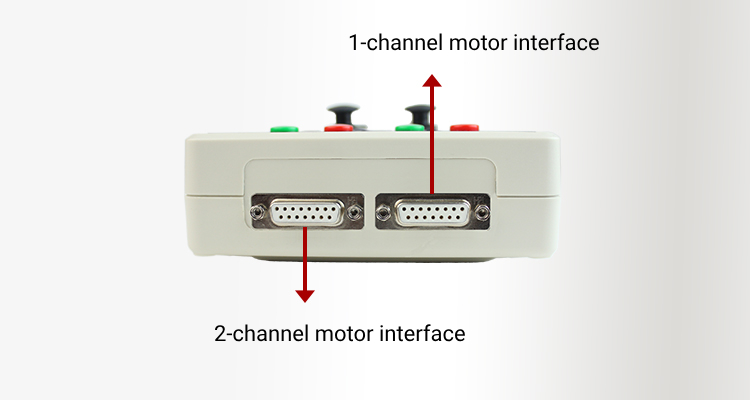

Multi-channel output to enhance work efficiency

It has 2 output channels, which can simultaneously drive 2 linear piezo motor displacement stages. The E53.D2E-K handheld piezo controller can simultaneously control multiple devices, significantly enhancing work efficiency, reducing equipment investment and operation time.

Description of the Operation of the Handle

II.

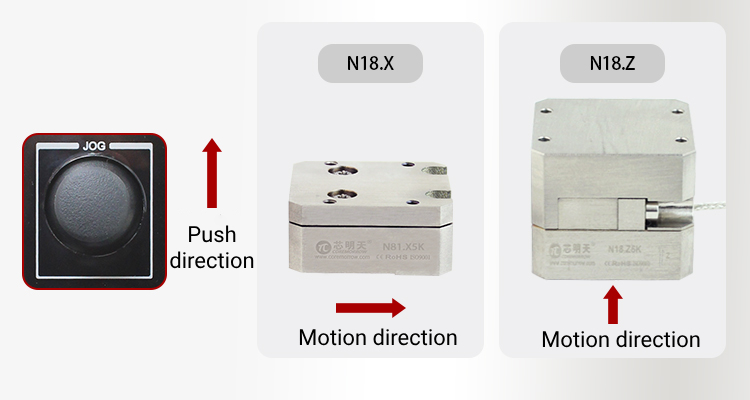

Take the control Coremorrow N18 piezoelectric motor as an example

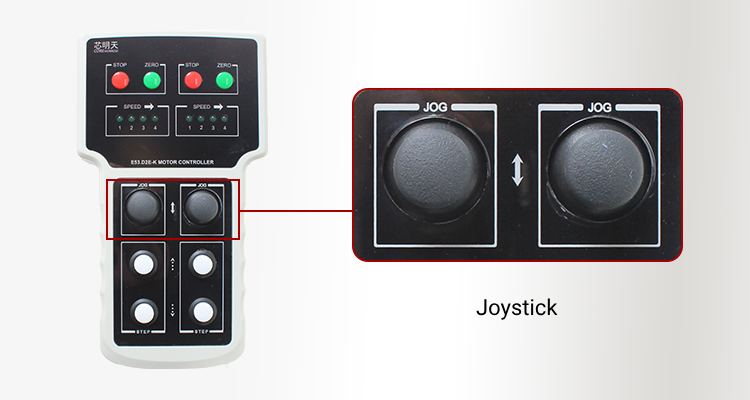

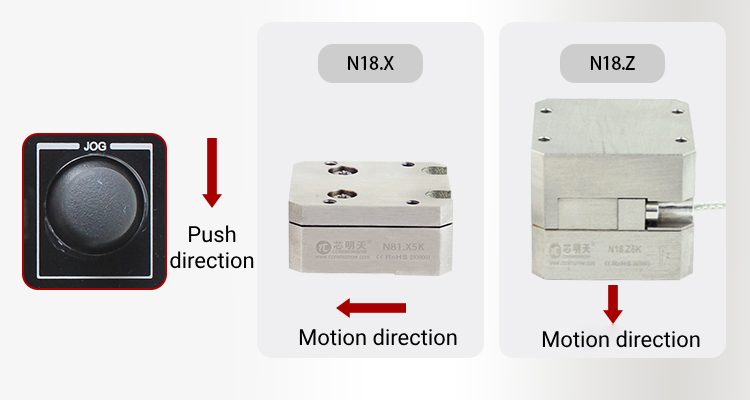

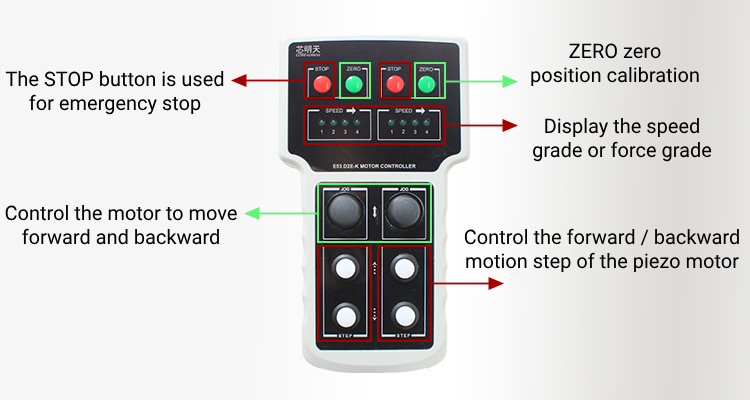

1 Joystick

When the joystick is pushed upwards, the piezo motor moves forward immediately. When the joystick is pushed downward, the piezo motor immediately retreats. When the joystick returns to its original position, the piezo motor immediately stops moving.

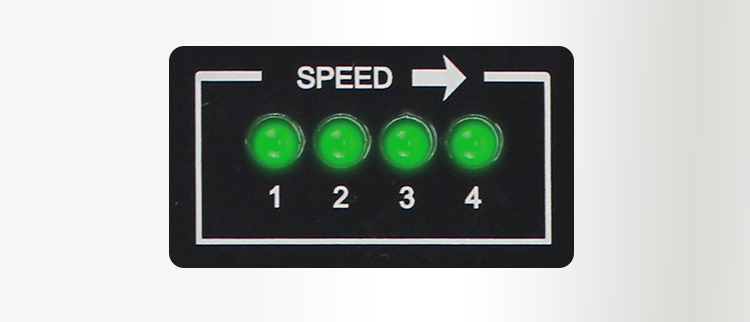

The joystick adopts a 9-level force-sensing design, converting the joystick's tilt angle into a quantifiable force level. As the joystick's tilt angle increases, the force level rises accordingly (from level 1 to level 9), and the real-time movement speed of the piezo motor also linearly increases simultaneously. In conjunction with the SPEED indicator light, the current intensity level can be visualized in real time. At the lowest level, all indicator lights are off. As the intensity increases, the indicator lights light up step by step from left to right. When reaching the highest level, all indicator lights light up simultaneously.

2 Buttons

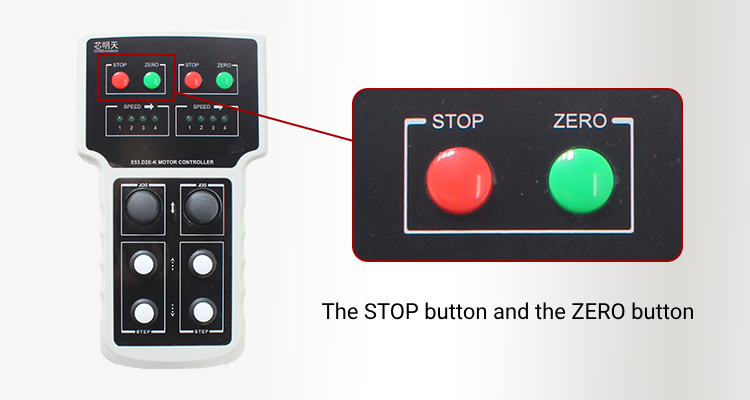

1)The STOP Button and the ZERO Button

In case of abnormal operation or misoperation and other emergency situations during operation, simply press the STOP button to trigger the emergency braking response and immediately stop the movement of the piezo motor displacement stage.

Press the ZERO button lightly, and the device will trigger the zero position calibration program, which can quickly control the piezo motor displacement stage to return to the set zero position reference point.

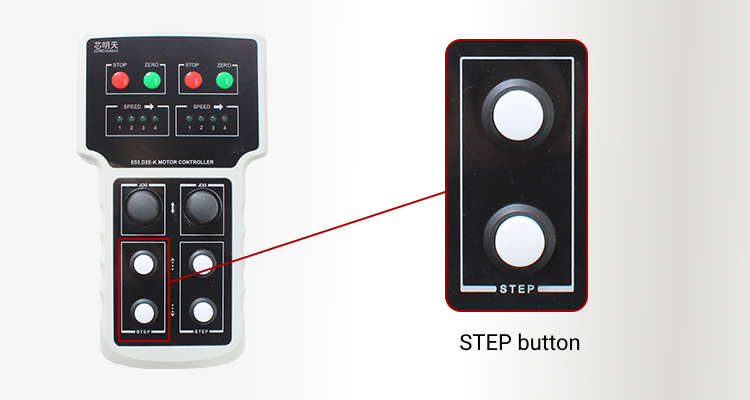

2)STEP Button

Each time the STEP button is pressed, the piezo motor moves one step. One of the two buttons controls the piezo motor to move forward, and the other controls the piezo motor to move backward.

Characteristics

III.

2 channels

24VDC/2.5A(20V~30V)power supply

Upper computer software control/handle control

Compact integrated design

Closed/open-loop servo available

Driving linear/rotation piezo motor stages

Technical Data

IV.

|

Model |

E53.D2E-K |

|

Servo control |

Closed-loop servo control |

|

Number of channels |

2 |

|

Power supply |

24V DC/2.5A(20~30V) |

|

Static power consumption |

<5W |

|

Processor |

32bit 480MHz |

|

D/A convertor |

16bit |

|

Communication interface |

TYPE-C、RS-422、RS-232 |

|

Output rating |

9W |

|

Working temperature |

0~50℃ |

|

Output short-circuit current |

60mA |

|

Piezoelectric connector |

DB15 |

|

Communication connector |

DB9、TYPE-C |

|

Size |

134×58×248mm³ |

|

Mass |

260g |

|

Control Method |

Digital signal control/handle control |

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.

- Previous article:No more

- Next article:How CoreMorrow Piezo Scanner Unlock Nano-world for Super-resolution Microscopy