P75.Z200S/K Large Stroke High Precision Piezo Objective Scanner

In the exploration of the microcosmic world, precise positioning is the key to success. Piezo objective scanner provides high-precision, high-stability objective positioning solutions in the fields of life science, materials science, semiconductors, etc., and has become the right-hand man for many precision operations. It uses advanced piezo actuator driving technology, by precisely controlling the voltage applied to the piezo actuators, it produces extremely small but precisely controllable telescopic changes. These tiny expansions are amplified and transmitted by a clever mechanical structure, enabling high-precision displacement adjustment of the objective lens. This working mode based on the inverse piezoelectric effect enables the piezo objective scanner to achieve accurate positioning on the micro scale, which provides a solid technical basis for meeting the needs of various high-precision applications.

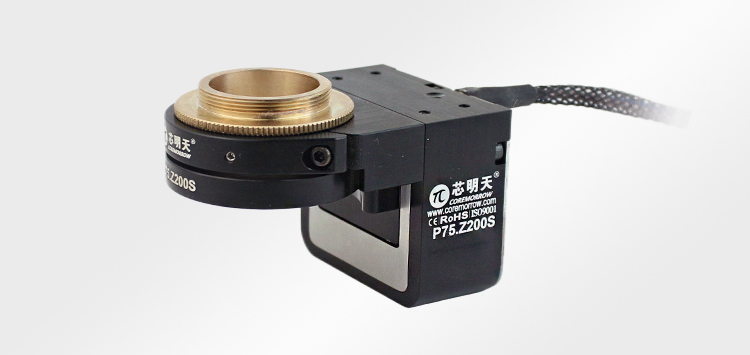

P75.Z200S/K Piezo Objective Scanner

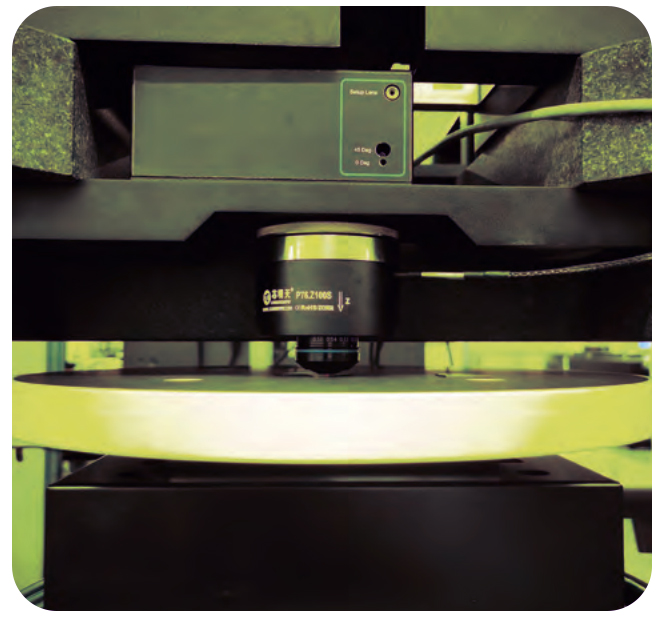

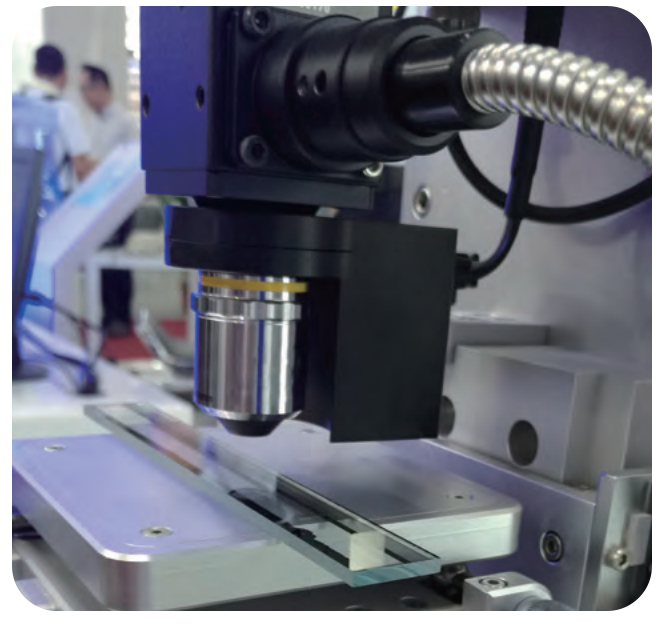

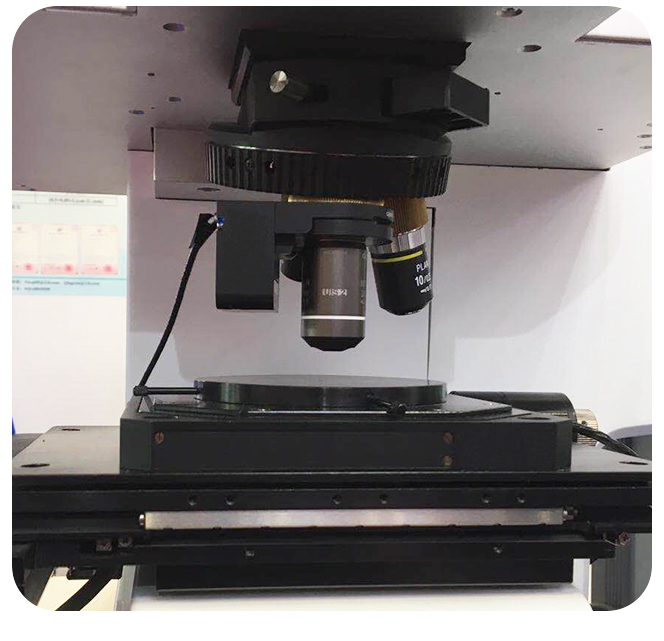

P75.Z200S/K piezo objective scanner can travel up to 250μm, and drive the objective lens within 0.2kg to do Z-axis movement. It uses a built-in high-performance piezo ceramics, and adopts parallel guide mechanism with flexure hinge without return error, no friction, good linearity, which can achieve nanoscale resolution, linearity and repetition, and high coaxiality. The objective lens has small compensation, millisecond response speed and ultra-high focusing stability. The compact design, small size, makes it very easy to integrate into various types of microscope systems. The use of separate thread adapter design, can be adapted to a variety of size object lenses, to provide customers with flexible adaptation solutions. The product is shown in the following figure.

Characteristics

Max. travel range to 250μm

Load capacity to 0.2kg

Unloaded resonant frequency to 389Hz

Design of separated thread adapter

High coaxiality

Applications

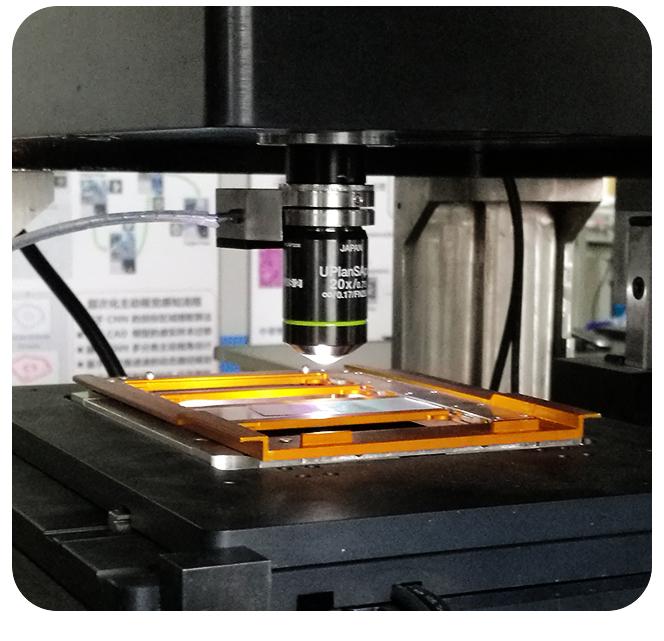

Piezo objective scanners can be used in fluorescence microscopy, confocal microscopy, ultra-high resolution microscopy and other devices to accurately locate cells and tissue samples, helping researchers to further study the structure and function of biomolecules.

The piezo objective scanner can be used in wafer cutting, lithography, laser direct writing and other manufacturing processes to improve the performance and production yield of the chip.

The piezo objective scanner can be used with atomic force microscopy for material characterization, nano-processing and other applications to study the structure and properties of materials at the microscopic scale.

Piezo objective scanner can be applied to white light interference. The piezo objective scanner can adjust the objective position in real time, accurately control the reference optical path and measure the optical path difference.

Technical Data

|

Model |

|

|

Active axes |

|

|

Drive control |

1driving channel ,1 sensing channel /1driving channel |

|

Nominal travel range(0~120V) |

|

|

Max. travel range(0~150V) |

|

|

Sensor |

|

|

Resolution |

|

|

Closed-loop repeatability |

|

|

Push/pull force |

|

|

Stiffness |

|

|

Unloaded resonant frequency |

|

|

Closed-loop working frequency(-3dB) |

|

|

Step time |

|

|

Load capacity |

|

|

El. capacitance |

|

|

Material |

Al, Steel |

|

Mass |

|

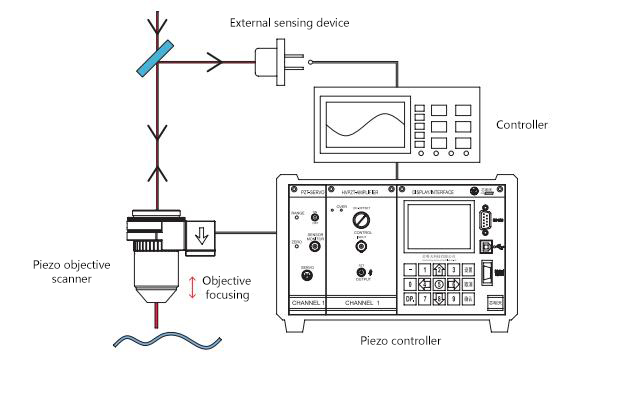

Recommended Controller

We recommend E53 series piezoelectric controller for driving the H01.6K-B4 fiber optic phase modulator. It is a single channel piezo controller, power supply 24VDC/1.5A, bandwidth 10kHz, which can be analog or digital control, and optional open/closed-loop. It has a compact structure and easy to be integrated, was developed for small size applications. According to the different functions, it can be divided into E53.A(analog control), E53.B (analog, servo control), E53.C (analog and digital control), E53.D (analog and digital control, servo control), the product is shown as below.

For more details, please contact CoreMorrow by calling 0451-86268790/17051647888 (Wechat ID).