- Introduction

- Feedback

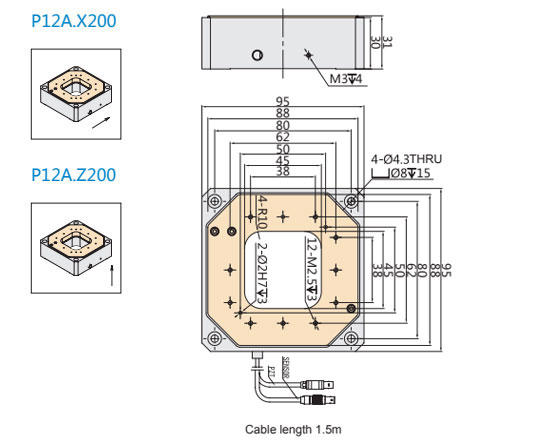

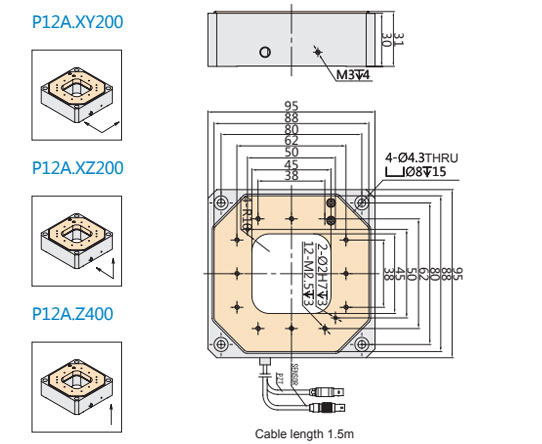

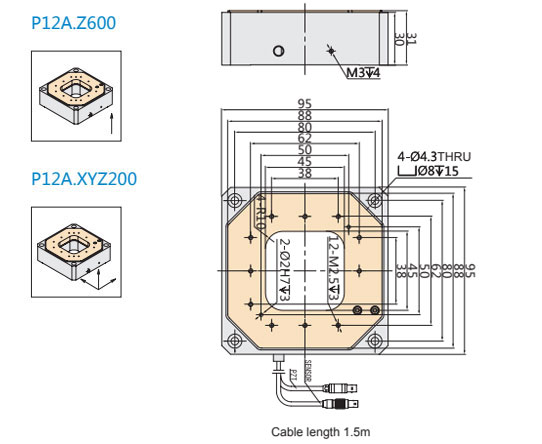

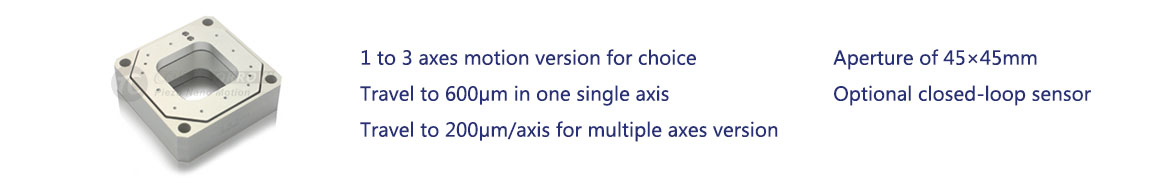

Characteristics

|

|

|

|

|

|

|

|

|

|

Applications

|

|

|

|

|

|

|

|

Note: Above are measured using E00/E01 piezo controllers. The max driving voltage can be -20V~150V; Recommended voltage 0~120V for high-reliability and long-term use.

| Mounting Method |

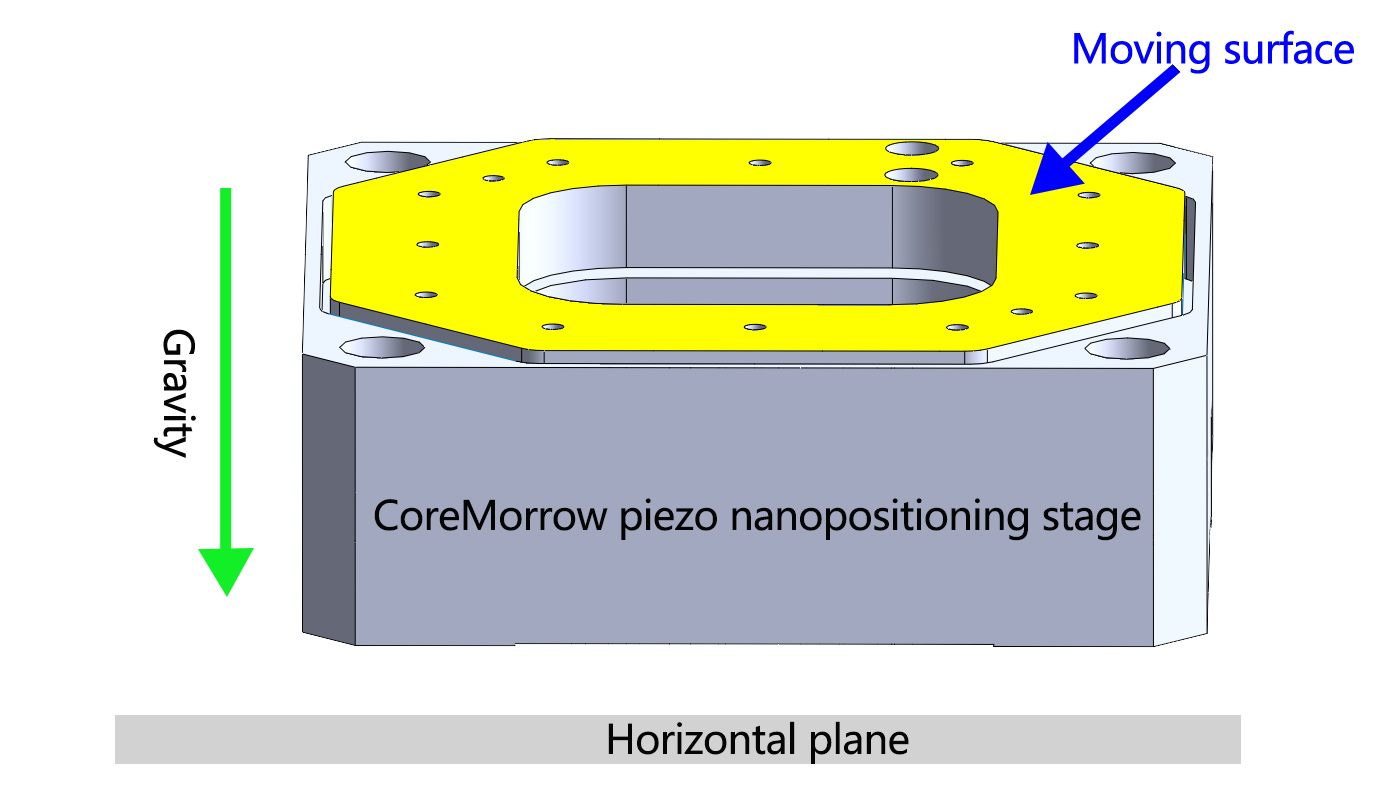

Horizontal Mounting |

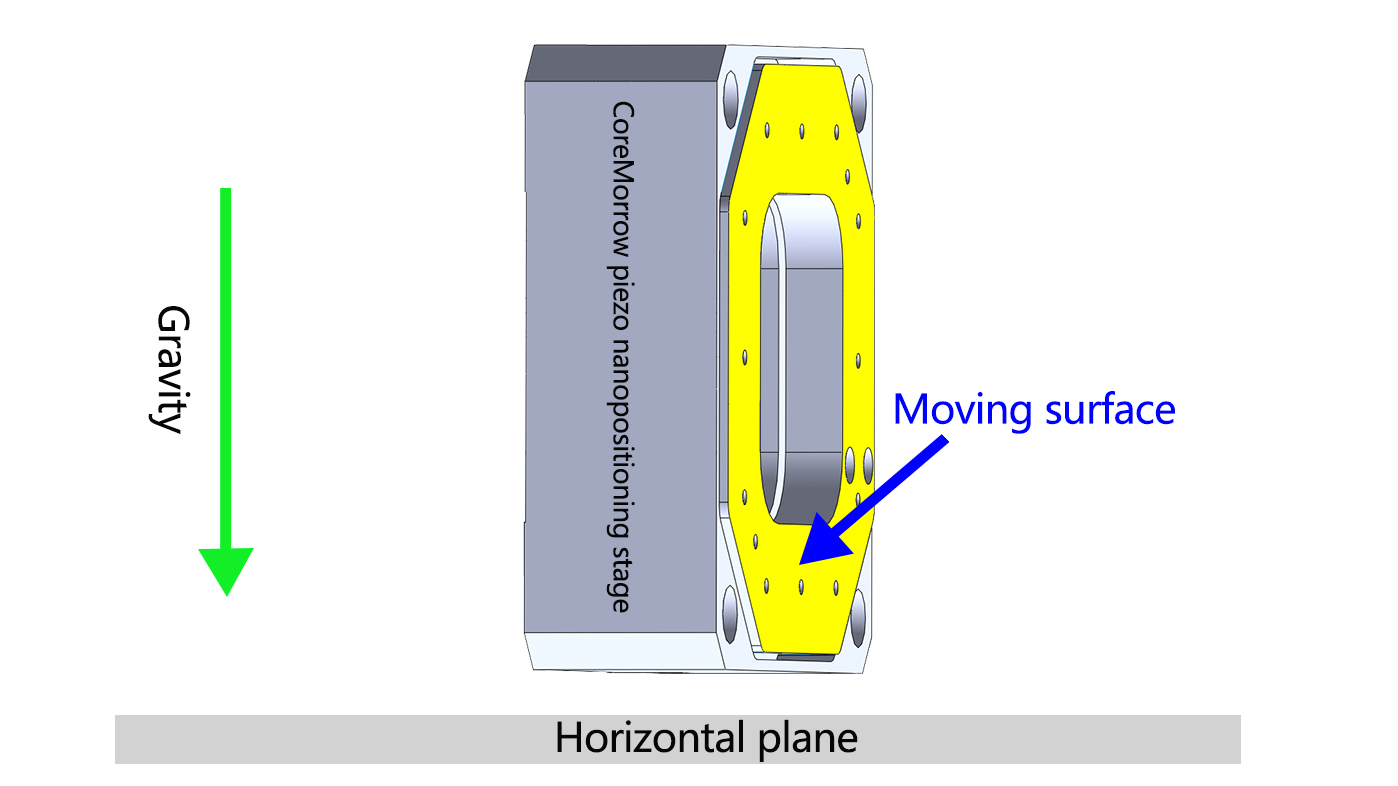

Vertical Mounting |

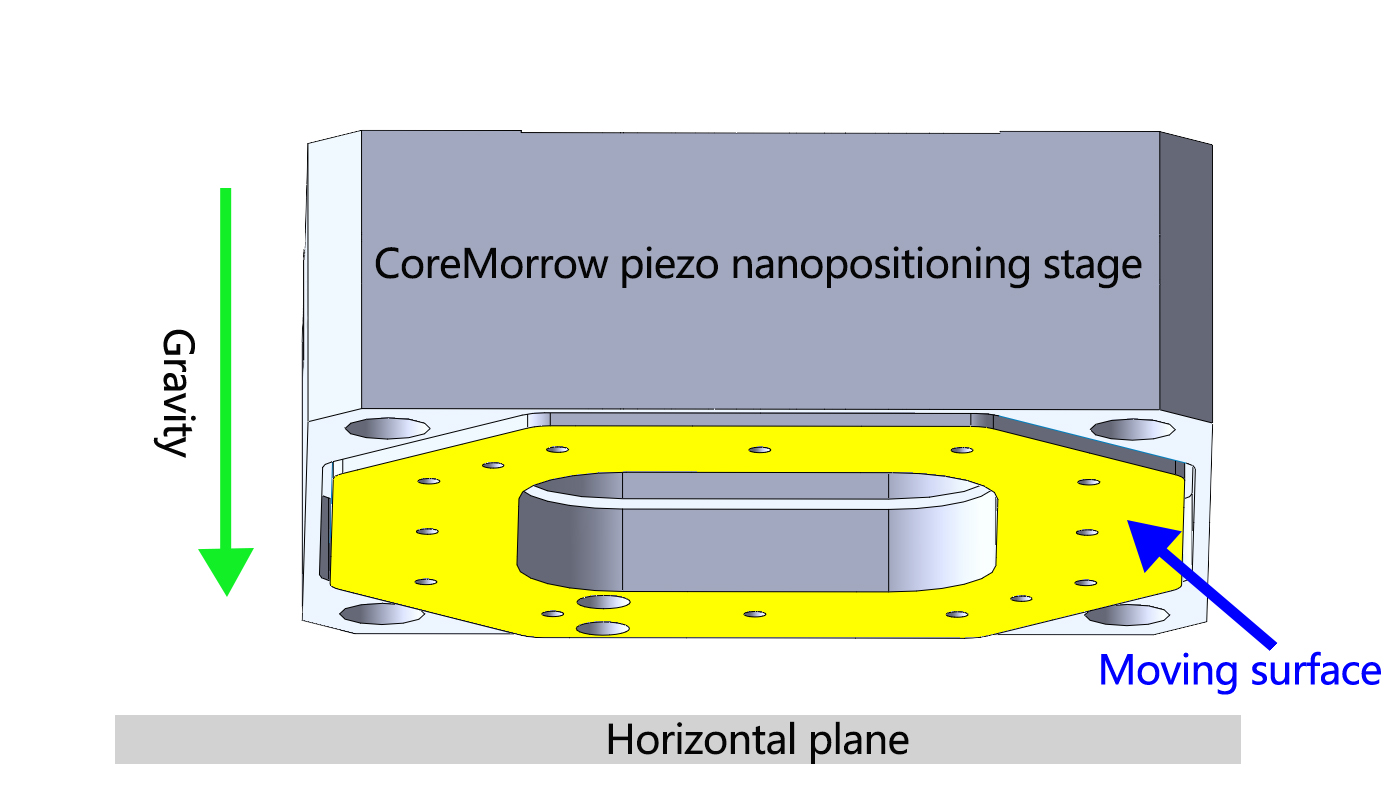

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

|

|

|

|

||||||

|