New Product | H81A. XYZ20S/K 3-axes Piezo Macromicro Composite Stage

Macromicro composite cross-scale two-stage drive precision positioning technology is one of the key supporting technologies in the fields of national defense, aerospace, precision machining, biological science and precision optics. With the development of science and technology, precision positioning technology has an increasing demand for the stroke and accuracy of positioning system. Macromicro composite two-stage drive precision positioning technology overcomes the technical problems that traditional single drive positioning technology is difficult to achieve large stroke and high precision, and has great advantages in volume, stroke, response speed, positioning accuracy and other aspects.

CoreMorrow carrys out research and development based on the practical application, to overcome the technical difficulties, the perfect combination of manual adjustment micro platform and piezo nano positioning stage, the positioning stage stroke extended to tens of millimeters, and can reach the resolution of nanometer level, in order to meet the requirements of different large stroke, high precision applications.

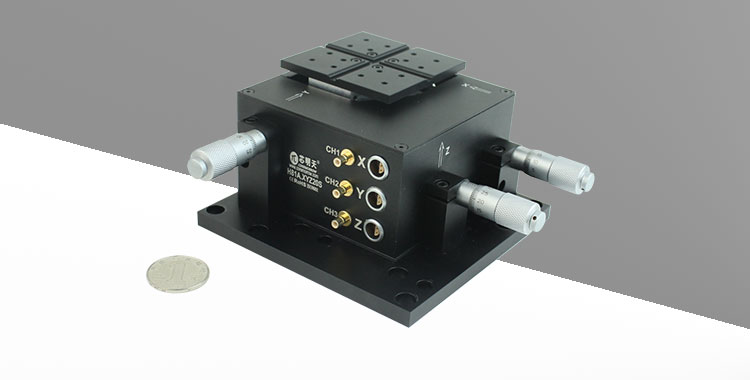

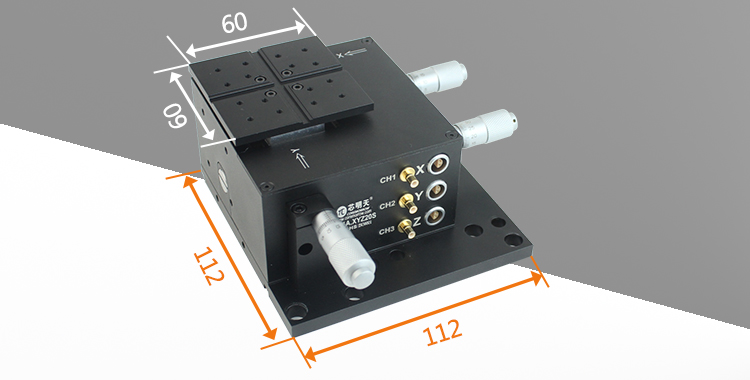

This paper introduces a macromicro composite cross-scale two-stage piezo platform H81A.XYZ20S/K. It can generate motion in three axes, with a micrometer stroke of 4mm per axis and a piezo stroke of 18μm. The physical appearance is shown in the following figure.

One end of the piezo macromicro composite platform H81A.XYZ20S/K has a moving table with a 60mm×60mm size and 16 M3 load mounting holes on the moving table surface. The platform is fixed on a base of 112mm×112mm, and there are 8 φ8mm and 3 φ6.4mm through holes on the base, so as to facilitate the fixed installation of the piezo macromicro composite platform.

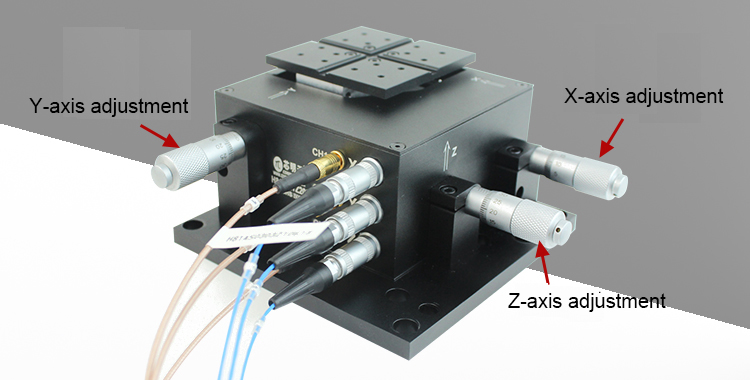

Manual Micrometer Adjustment Combined with Piezo Nano Adjustment

The piezo macromicro composite platform H81A.XYZ20S/K is adjusted by a manual micrometer with a stroke of 4mm and a single turn of 500μm.

The piezo driving part of the macromicro composite platform is driven by piezo ceramics and controlled by voltage signal. The voltage signal is applied to the piezo ceramics inside the piezo platform by CoreMorrow piezo controller, and the corresponding displacement is generated by the piezo ceramics, and then transmitted to the mobile table by the flexible structure, so that the mobile table generates micro and nano micro displacement motion.

The part of the piezo drive is connected with the piezo controller and the piezo macromicro composite platform through the lead and connector. Both ends of the lead wires of the piezo system are connected by connectors.

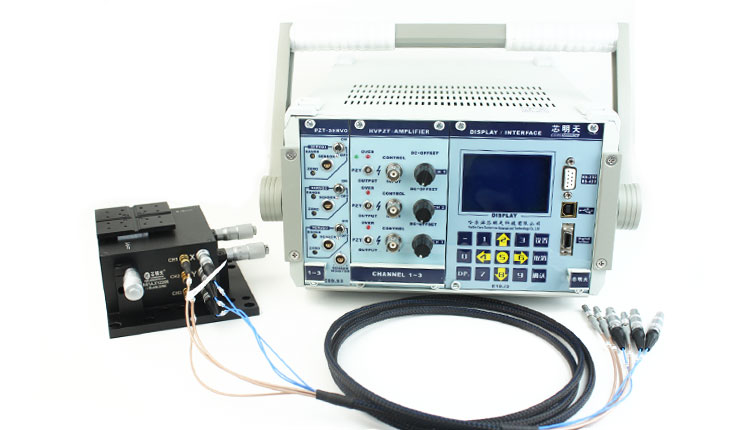

Auxiliary Piezo Controller

E01.D3 series piezo controller is very suitable for driving H81A.XYZ20S/K piezo macromicro composite platform. It has a closed-loop servo module, which can be controlled by servo. In addition, it can be controlled by the upper computer software.

Technical data

The basic parameters of H81A.XYZ20S/K piezo macro/micro composite platform driven by piezo controller E01.D3 are as follows.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For more details, please contact us by calling 0451-86268790, 17051647888 (wechat ID).

- Previous article:Piezo Nano-positioning Stage Applied to Data Storage

- Next article:Piezo Nanomotion Products Applied to Lasers!