Application of Piezo Technology in TDLAS Gas Detection

Gas detector is a common gas concentration detection instrument, mainly using gas sensor to detect the types of gases in the environment. It can detect hydrogen sulfide, carbon monoxide, oxygen, sulfur dioxide, phosphine, ammonia, nitrogen dioxide, hydrogen cyanide, chlorine, chlorine dioxide, ozone and combustible gas, etc., which is widely used in petrochemical, coal, metallurgy, chemical industry, municipal gas, environmental monitoring, agriculture and other sites for site testing. In addition, it can also used for the special occasion measurement needs, such as concentration detection or leakage in tunnel, pipe, tank, confined space and so on.

Tunable Diode Laser Absorption Spectroscopy (TDLAS) is a technology that uses a Tunable Diode Laser and Laser Absorption Spectroscopy to measure the concentration of certain substances (such as methane and water vapor) in a gas mixture. The advantage of TDLAS over other concentration measurement is its ability to achieve very low detection limits (PPB class). In addition to the concentration, the temperature, pressure, velocity, and mass flux of the observed gas can be also determined. TDLAS is by far the most common laser-based absorption technique used to quantitatively assess substances in the gas phase.

TDLAS tunable diode laser absorption spectroscopy technology is used to measure single or several absorption lines of molecules that are very close to each other and difficult to resolve by using the characteristics of narrow linewidth and wavelength of tunable semiconductor laser with modulation.

TDLAS technology is mainly used to detect gas by detecting a single vibrational absorption line of the gas molecule. When detecting low concentration gas, because the absorption signal is weak, it is usually necessary to combine long optical path technology and harmonic detection method to improve the sensitivity of gas detection. According to the Lambert-Beer law, when a beam of light will decay when passes through gas.

Principle of TDLAS Gas Detection Technology

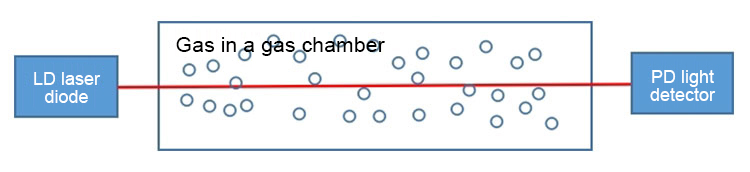

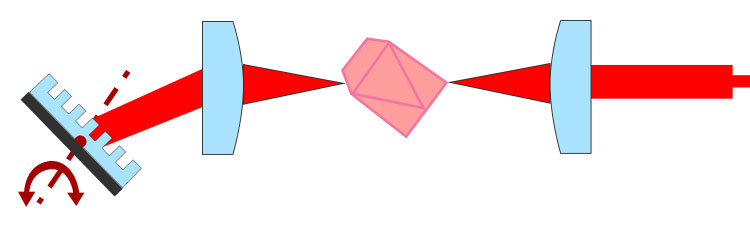

Schematic diagram of TDLAS gas detection

Schematic diagram of TDLAS gas detection

When laser diode light goes through gas chamber, PD light detector will receive LD optical power.

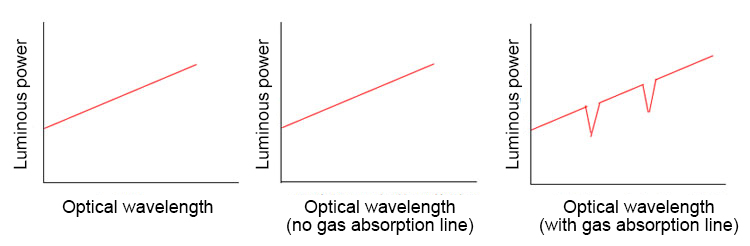

With the modulation, the output optical power and wavelength of the laser will change accordingly. After passing through the gas cavity, the corresponding output optical power and wavelength will also change. If the light is not absorbed by the gas within the wavelength sweep range, that is, there is no gas absorption line, then the optical power received by PD is the same as the optical power output by LD. If there is an absorption line in the wavelength range, the line spectrum of the optical power received by the PD terminal will have a depression, and the type and intensity of the gas can be determined by the wavelength and depth of the depression.

In order to reflect real light absorption, laser wavelength or frequency curve must be scanned.

Basic Method of Frequency Control in TDLAS Gas Detection

In general, there are four basic ways to adjust the frequency of light coming out of a laser, namely, changing the temperature of the diode, changing the voltage of the piezoelectric actuator (which controls the position and Angle of the grating), adjusting the current driving the laser diode, and changing the voltage of the EOM inside the cavity.

The intracavitary EOM method is less common and can change the refractive index quickly, but the range of frequency adjustments is usually very small.

By changing the temperature of the diode, the laser frequency (tuning coefficient is generally 0.1nm/K) can be greatly changed, so as to achieve the purpose of wavelength scanning. But it takes a long time for the diode temperature to change, usually a few seconds, which is only suitable for adjusting the approximate range of wavelengths.

Adjusting the current driving the laser diode changes the refractive index of the semiconductor and therefore the frequency. The typical tuning factor is about 0.1GHz/mA. The modulation current allows modulation of laser frequencies with a bandwidth of several MHz. Therefore, it is a typical "actuator" for reducing laser linewidth.

Piezoelectric adjustment is a very fast adjustment, which can adjust the grating position and Angle in millisecond or even submillisecond to meet the requirements of rapid frequency change. Moreover, the frequency can be adjusted over a wide range, from a few Hz to kHz, by piezoelectric adjustment method.

In addition, piezo adjustment methods are often used to counteract slower frequency shifts.

Frequency Control Based on Piezoelectric Technology

Typically, piezo actuators are actuator components used to lock phase and frequency feedback loops. It performs phase and frequency adjustments based on control signals.

Because the absorption spectral lines of different gases to be measured are different, the output laser wavelength of the laser needs to change periodically, so that the central wavelength of the laser is adjusted to the absorption spectral line of the gas to be measured, and selective absorption is generated. The periodic change of the output wavelength of the laser can be adjusted by the piezo actuator. The piezo actuator has the characteristics of fast response speed and high precision, and is very suitable for adjusting the output spectral line.

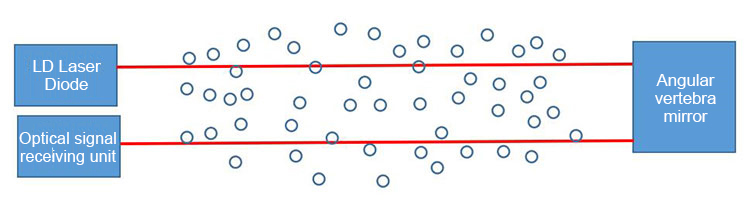

Piezo actuators are not only used in TDLAS gas detection technology, but also in OPLAS open-circuit gas detection and analysis.

OPLAS (Open Path Laser Absorption Spectroscopy) is similar to TDLAS, but OPLAS does not need to pump the sample gas into the gas absorption unit for analysis. The OPLAS system has higher requirements for laser point quality and optical equipment. For example, the detection of low concentration of ammonia is relatively difficult, in the detection of low concentration of ammonia gas environment, the piezo actuator can be used to adjust the direction of the light source, quickly locate the laser scanning center position, and then take fast laser scanning in a certain range. The method can even detect gas concentrations over a distance of 1,000 meters.

OPLAS Basic Structure Drawing

Selection of Piezo Actuators for TDLAS Gas Detection

CoreMorrow has thousands of piezo actuators and the corresponding drive control products. The selection of piezo actuators mainly depends on the specific structure of the corresponding TDLAS gas detection and the corresponding need to adjust the optical path parameters.

Usually, the volume of the gas detector is small, so the smaller the component size, the better.

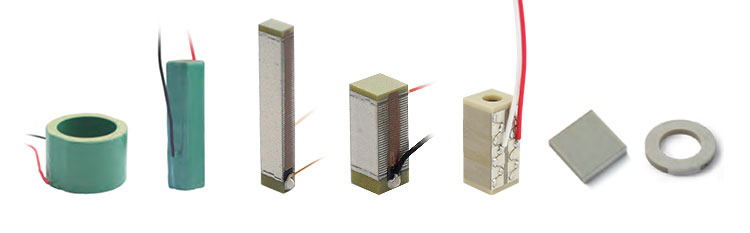

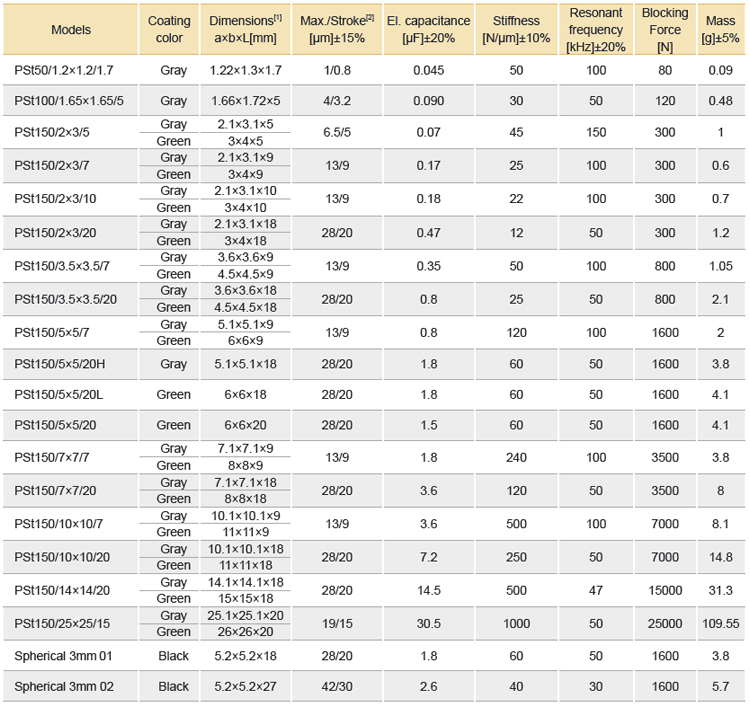

1)CoreMorrow Piezo Stack Actuator

CoreMorrow PZT stack actuators come in a wide range of sizes and models, with the smallest size up to 1.22 x 1.3 x 1.7mm^3 and displacement up to 1μm. The cross-sectional area of the piezo stack is 1.22 x 1.3 mm ^ 2, 1.66 x 1.72 mm ^ 2, 2 x 3 mm ^ 2, 3.5 x 3.5 mm ^ 2, 5 x 5 mm ^ 2, 7 x 7 mm ^ 2... 25 x 25mm^2, the larger the cross-sectional area, the higher the output. The height can be selected according to the desired displacement range value. The higher the height, the greater the displacement.

The final selection will depend on factors such as output requirement, displacement requirement and space limitation.

CoreMorrow Piezo Stack Actuator

Technical data of CoreMorrow Piezo Stacks

Note: Due to a large number of product models, only part of them are shown here. For more information, please contact our sales engineer.

2) CoreMorrow Preloaded Piezo Actuators

In order to get better protection and application, CoreMorrow provides preloaded piezo actuators, with piezo ceramic stacked and encapsulated in the interior, so that they are protected from the impact of knock, humidity and so on.

In addition, the piezo actuator is preloaded internally to make it more suitable for dynamic applications.

CoreMorrow Preloaded Piezo Actuators

CoreMorrow Preloaded Piezo Actuators

The moving end of the preloaded piezo actuators can be connected with flat head, ball head, internal thread, external thread, or customized connection.

Technical data of CoreMorrow Preloaded Piezo Actuators

Note: Due to a large number of product models, only part of them are shown here. For more information, please contact our sales engineer.

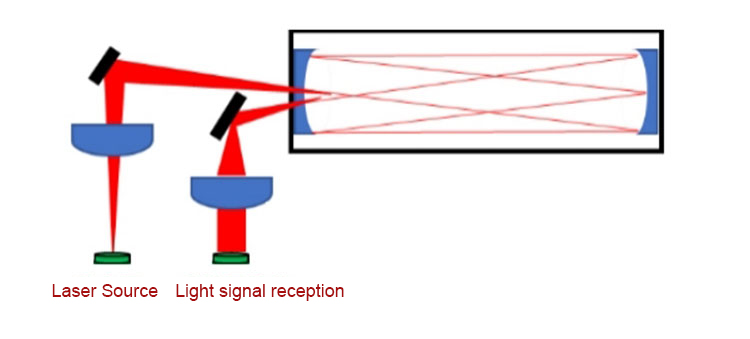

Absorption Sensitivity can be Improved by Increasing Length of Gas Chamber

For the detection of lower concentrations of gases, higher gas absorption sensitivity is required.

The sensitivity of gas absorption can be improved by increasing the length of the gas chamber, but this will result in the volume of the gas detection equipment becoming larger. To solve this problem, many gas detection devices have special low-loss mirrors at both ends of the gas chamber. The light emitted by the laser is reflected back and forth in the gas cavity by the reflection lens, so that the light has more contact with the gas, and the distance of the light through the gas becomes longer, so as to improve the high sensitivity of the test, and the weak absorption line can also be detected.

Note: For reference only, different systems have different structures

Light oscillates back and forth in the gas chamber, so the LD line width needs to be as narrow as possible.

Of course, the above is just one of the TDLAS structures, and the structure of each TDLAS device will be different.

List of Gas Sensitive Wavelengths

Gas sensitive wavelength parameters in the following table for your reference:

|

Molecule |

MIR

|

NIR

|

Typical Application |

||

|

(ppb) |

Wave Length (nm) |

(ppb) |

Wave Length (nm) |

||

|

H2O |

2.0 |

5940 |

60 |

1390 |

Process Control |

|

CO2 |

0.13 |

4230 |

3000 |

1960 |

Combustion system, coal mine, hypoxia protection, smoke control |

|

CO |

0.75 |

4600 |

30000 |

1570 |

|

|

- |

- |

500 |

2330 |

||

|

NO |

5.8 |

5250 |

60000 |

1800 |

|

|

- |

- |

1000 |

2650 |

||

|

NO2 |

3.0 |

6140 |

340 |

680 |

|

|

N2O |

0.44 |

4470 |

1000 |

2260 |

|

|

SO2 |

14 |

7280 |

- |

- |

|

|

CH4 |

1.7 |

3260 |

600 |

1650 |

Natural gas extraction and pipelines |

|

C2H2 |

3.5 |

7400 |

80 |

1520 |

|

|

HF |

- |

- |

10 |

1310 |

Process Control |

|

HCl |

0.83 |

3400 |

150 |

1790 |

Oil Refinery |

|

HBr |

7.2 |

3820 |

600 |

1960 |

|

|

HI |

- |

- |

2100 |

1540 |

|

|

HCN |

12 |

6910 |

290 |

1540 |

Process Control |

|

H2S |

- |

- |

20000 |

1570 |

|

|

O3 |

11 |

9500 |

- |

- |

Air contamination measurement |

|

NH3 |

0.8 |

10300 |

800 |

1500 |

Refrigerated food manufacturing, processing and preservation, |

|

CH2O |

8.4 |

3550 |

50000 |

1930 |

Process Control |

|

PH3 |

6.2 |

10100 |

1000 |

2150 |

|

|

O2 |

- |

- |

78000 |

760 |

Hypoxia protection |

- Previous article:CoreMorrow E00/E01.A -500V~+1500V High Voltage Amplifier

- Next article:CoreMorrow Nano Motion - Fast Tool Positioning Stage