New Product - N55.Z10 Large Load Linear Piezo Motor Stage

In the fields of precision manufacturing and scientific research, every technological innovation injects new vitality into the industry's development. As a company that has been deeply engaged in piezoelectric nano-positioning systems for 20 years, CoreMorrow's piezo motor, with its millimeter-level stroke and nano-level precise control, has long become a reliable assistant in many precise applications. Its applications mainly covers two core fields , precision manufacturing and cutting-edge scientific research. At the manufacturing end, whether it is the micro-nano level alignment of semiconductor chips or the high-precision positioning of micro-nano devices; In the field of scientific research, whether it is the nano-focusing and scanning control of optical systems or the subtle movement control of samples in super-resolution imaging experiments, its stable operation can always be seen.

N55.Z10 linear piezo motor represents an innovative breakthrough we have initiated on the basis of precision towards greater load capacity, larger stroke, more flexible integration, and more intelligent control. It is not a replacement for traditional products, but offers new options for different applications.

I. Highlights: Structure and Motion Transformation

N55.Z10 linear piezo motor has three-part structure of "upper platform - trapezoidal wedge - base". Through the internal piezo drive, the horizontal motion of the trapezoidal slider is combined with the inclined surface, which is converted into the Z-motion of the upper platform.

When the piezo ceramic drives the trapezoidal slider to move left and right horizontally, due to the coordination between the inclined surface of the trapezoidal slider and the upper and lower structures, the change in the position of the slider will cause the vertical distance between the upper platform and the base to change. When the trapezoidal slider moves left and right, the height difference of the inclined surface is utilized for transformation, enabling the upper platform to achieve displacement in Z-axis. This design converts horizontal movement into vertical displacement, thereby achieving a greater load capacity in Z while ensuring high-precision displacement control. By taking advantage of the geometric characteristics of the trapezoidal structure, the load pressure is dispersed, the overall rigidity is enhanced, and the load capacity is strengthened.

II. Core Performance Enhancement: Longer Travel, Larger Load

01

Balance Long Travel and High Precision

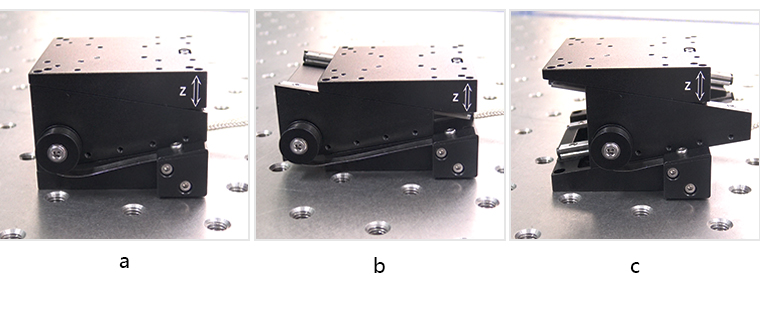

N55.Z10 linear piezo motor stage has extended its stroke to a certain extent, as shown in Figure a. If N55.Z10 is set to the 0 position, the Z-axis displacement is 0. As shown in Figure b, when the trapezoidal slider moves to the minimum value in the negative direction of the X-axis, the Z-axis displacement reaches the minimum negative value, with a displacement of -5.5mm. As shown in Figure c, when the trapezoidal slider moves to the maximum value in the forward direction of the X-axis, the Z-axis displacement reaches the maximum positive value, with a displacement of +5.5mm. Assuming the 0-position state as the reference, under loading conditions, the N55.Z10 can achieve a flexible total displacement of 11mm in both directions along the Z-axis.

Meanwhile, due to the millimeter stroke achieved through structural transformation, it also relies on the micro-deformation of the built-in piezo ceramics. Even with a large stroke, it still maintains nanometer-level control accuracy.

02

Enhanced load capacity

The inclined plane design of the trapezoidal structure can convert the horizontal driving force into a greater Z-direction supporting force through the decomposition of force. The Z-direction load capacity of the N55.Z10 linear piezo motor stage can be up to 1kg or more.

03

Equipped with Grating Sensor, Offering Higher Positioning Accuracy

The closed-loop version of N55.Z10 linear piezo motor stage is equipped with a high-precision grating sensor, which can capture the minute displacement changes of the platform in real time. In the overall stroke range of 11mm in Z, when combined with the piezoelectric drive system, a positioning accuracy of 0.2μm can be achieved, which can perfectly adapt to scientific research and high-end manufacturing scenarios with extremely high requirements for ultra-precise positioning, such as photonic device packaging and nanoimprint.

III. Scene Adaptation: Compatible with Multiple Applications

Anti-Interference and Long-Term Stability

1

N55.Z10 linear piezo motor stage utilizes the stick-slip principle and an integrated trapezoidal structure to eliminate or reduce transmission clearance, minimize mechanical wear, ensure continuous operation without fluctuation errors, and have a small long-term drift. It is suitable for scenarios with strict stability requirements, such as semiconductor manufacturing and microscopic alignment.

Adaptability to the Environment and Scenarios

2

N55.Z10 linear piezo motor stage is driven by the piezoelectric effect and can operate stably within a wide temperature range and in a vacuum environment. It is resistant to strong electromagnetic interference and is suitable for complex scenarios such as biomedicine and semiconductor industries.

IV. Technical Data

The innovative design of the N55. Z10 has achieved multi-dimensional performance improvements of "long stroke, high precision, large load, and anti-interference", providing a more reliable precision motion control solution for high-end fields such as micro-nano processing, optical inspection, and semiconductor manufacturing.

|

Model |

N55.Z10E |

|---|---|

|

Active axis |

Z |

|

Sensor |

Grating sensor |

|

Nominal travel range |

11or±5.5mm |

|

Max. speed |

0.5mm/s |

|

Resolution |

5nm |

|

Repeatability |

0.2μm |

|

Load capacity |

1kg |

|

Working temperature |

0~50℃ |

|

Material |

Al, stainless steel |

|

Mass |

275g |

|

Dimension |

60mm×52mm×37mm |

|

Recommended Controller |

E53.D1E-J |

V. Recommended Controller

53.D1E-J small-sized piezo controller is specially designed for driving piezo motors and is suitable for driving the N55.Z10 stage. It is a single-channel closed-loop piezo controller with digital control, 24VDC power supply, static power consumption less than 5W, and TYPE-C, RS-422, and RS-232 communication interfaces. It has a compact structure with dimensions of only 105×103×30.1mm^3 , easy to integrate and operate.

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.