How Piezo Actuators Improve the Coating of Lithium Batteries

With the rapid development of the electric vehicle industry, lithium batteries, as the core power source, have increasingly strict requirements for production processes. Electrode coating, as a crucial step in the production, its uniformity and consistency directly affect the energy density, safety performance and cycle life of the batteries. In this precise manufacturing process, piezo actuators, with their unique technical advantages, became one of the core components that can achieve ultra-high-precision coating control.

I. Lithium Battery Coating: Seemingly Simple, Actually Crucial

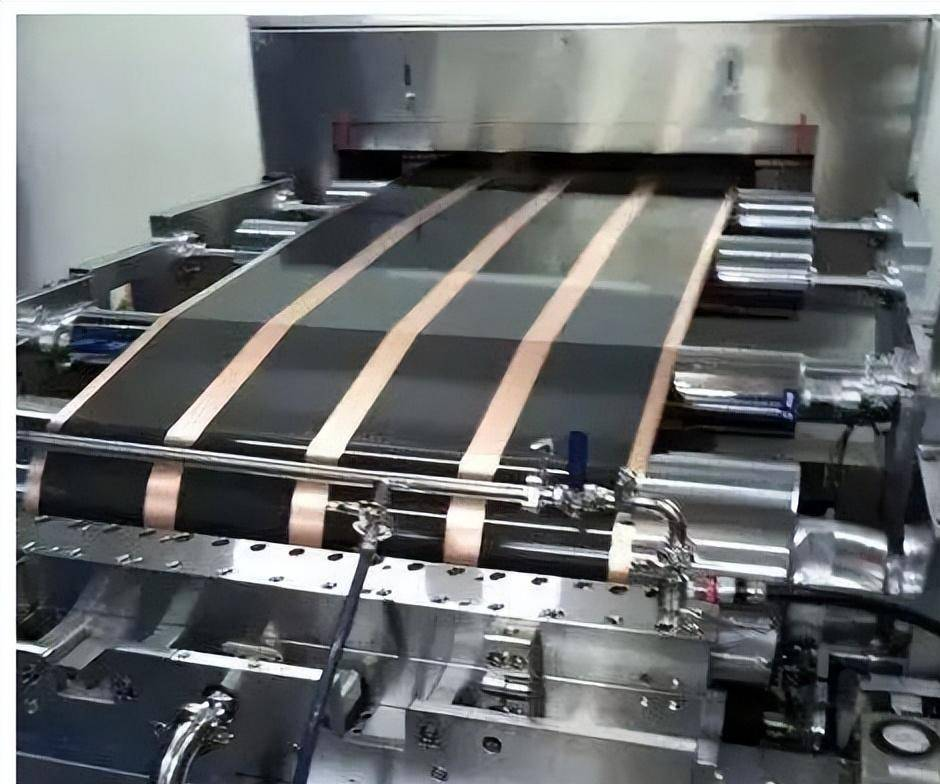

Lithium battery electrode coating refers to the process of evenly coating the prepared electrode slurry (positive or negative electrode material) on the surface of metal foil (aluminum foil or copper foil). After going through subsequent processes such as drying, these slurries will form electrode sheets. This step is like dressing the lithium battery in a uniform energy coat, laying the foundation for the subsequent charging and discharging process. The core purpose of coating is to enable the electrode material to adhere evenly and stably to the substrate, thereby ensuring the efficient conversion and storage of electrical energy during the charging and discharging process of lithium batteries. The uniformity of coating, thickness consistency and edge neatness directly determine the characteristics of the battery:

1. Energy density:The more uniform the coating, the more stable the battery capacity and performance.

2. Safety:Coating defects may lead to local overheating or even thermal runaway.

3. Cycle life:Large fluctuations in coating thickness can easily cause accelerated aging of the battery.

(Note: Image from online resources)

Especially batteries for electric vehicles, the electrode length can be up to hundreds of meters. Any slight coating deviation may lead to a decline in the performance of the entire batch of batteries or even their scrapping. Therefore, there are extremely high requirements for the coating process: precision, speed and response.

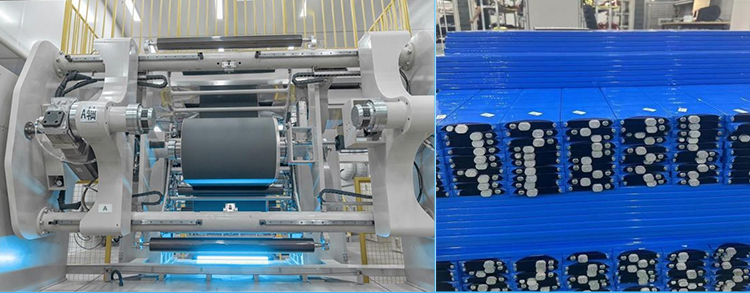

Three core requirements for the coating process of lithium batteries:

1.Thickness control:

2.Good stability:

3.Dynamic response:During high-speed operation, it is necessary to be able to promptly adjust the position of the coating scraper or coating head to compensate for other interferences.

(Note: Image from online resources)

II. CoreMorrow Piezo Ceramic Actuator: Precise Coating, Driving the Future

Piezo actuators, based on the inverse piezoelectric effect, generate nanometer-level high-precision displacement through voltage drive, and their characteristics are highly consistent with the requirements of coating processes:

1.High-Precision Positioning

Piezo actuators can achieve nano-scale displacement resolution. Through closed-loop control, the opening degree of the coating scraper or mold coating can be adjusted in real time to precisely control the thickness of the slurry, avoiding over-coating or under-coating.

2.Quick Response

The response speed of piezo actuators can be millisecond. In high-speed coating, it can compensate in real time for disturbances such as changes in substrate tension and fluctuations in slurry pumping, ensuring the uniformity of the coating.

3.No Friction and High Rigidity

The direct drive mechanism features high rigidity and requiring no maintenance for long-term use, making it particularly suitable for long-term continuous operation in clean environments.

(Note: Image from online resources)

For high-standard and large-scale manufacturing scenarios such as lithium batteries for electric vehicles, piezo actuators offer a more reliable and efficient solution: they can enhance coating consistency, increase battery energy density and safety, and also reduce the waste of slurry and lower production costs.

Low-Voltage Cylindrical Piezo Actuator

The low-voltage cylindrical piezo actuator is highly suitable for integration. Its exterior is protected by a cylindrical stainless steel casing, and a preload force is applied to the piezo stack through a mechanical housing. The high internal mechanical preload force can be applied to high-load and high-dynamic applications. CoreMorrow low-voltage cylindrical piezo actuator can provide nanometer-level resolution, millisecond-level response time, and travel up to 190 μm.

Characteristics

• Nanoscale resolution

• Optional closed-loop sensor

• Travel to 190μm

• Blocking force to 25000N

• Outer diameter, height and displacement all on request

Technical Data

|

Nominal travel range |

8μm~190μm |

|

Stiffness |

5N/μm~500N/μm |

|

Pull force |

200N~7300N |

|

El.capacitance |

0.17μF~145μF |

|

Resonant frequency |

3kHz~40kHz |

|

Length |

19.2mm~199mm |

Note: The length, diameter, pins and interface of the piezo actuator can all be customized as required.

Anti-Torque Preloaded Piezo Actuators

VT14 and VT17 preloaded piezo actuator with anti-torque design can effectively eliminate a certain amount of torsion in the process of mounting or others, and effectively protects the internal piezo stack from direct action, avoiding damage to the ceramics. It is compact in structure and very easy to integrate.

Characteristics

• Withstand torque, special mechanical housing

• Max displacement to 95μm

• Blocking force 1200N

• Sub-millimeter response time

Technical Data

|

Nominal travel range |

9μm~95μm |

|

Stiffness |

10N/μm~120N/μm |

|

Pull force |

1200N |

|

El.capacitance |

0.7μF~9μF |

|

Resonant frequency |

10kHz~40kHz |

|

Length |

19.4mm~100.4mm |

High-Voltage Cylindrical Preloaded Piezo Actuators

High voltage cylindrical preloaded piezo actuators is a cylindrical piezo stack with mechanical preload and driving voltage of 1000V. It could withstand some certain pulling force, built-in piezo stack with large blocking force up to 50000N, mainly used for dynamic applications of large loads.

Characteristics

• 1000V driving

• Stroke to 260μm

• Load capacity to 70000N

• Open/closed loop

• Customizable

• Outer diameter Ø18mm, Ø25mm, Ø35mm, Ø45mm

Technical Data

|

Nominal travel range |

7μm~260μm |

|

Stiffness |

10N/μm~4000N/μm |

|

Pull force |

4000N~50000N |

|

El.capacitance |

20nF~6500nF |

|

Resonant frequency |

3kHz~40kHz |

|

Length |

24mm~194mm |

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.

- Previous article:No more

- Next article:Piezo Fiber Stretcher: Precise & Rapid Adjustment of Fiber Length & Diameter!