How Piezoelectric Nanotechnology Upgrades and Evolves Optical Fiber Switches

Optical communication is now in a golden period of rapid development. As an intelligent transportation hub of optical networks, fiber optic switches play a decisive role in the performance of the entire communication system. With the rapid development of 5G, data centers and the Internet of Things, traditional fiber optic switches are also facing unprecedented challenges in terms of accuracy, speed and reliability. The breakthrough application of piezoelectric nanotechnology is bringing revolutionary changes to fiber optic switches.

I. Optical Fiber Switch

The intelligent Conductor of Optical Communication

An optical fiber switch is a device used in optical fiber communication, optical networks or optical test systems to accurately and quickly control the path switching, on-off or routing of optical signals. Optical fiber switches directly operate on optical signals. Their core function is to achieve selective connection, disconnection or switching of optical paths, and they are one of the core components for building optical networks.

(Note: Image from online resources)

According to Different Control Methods, Optical Fiber Switches are mainly Divided into Two Categories:

1. Mechanical Optical Fiber Switch

Optical path switching is achieved by physically moving optical fibers or optical components. This type of switch generally has advantages such as low insertion loss, high isolation, and insensitivity to polarization, but its switching speed is relatively slow, and the lifespan of the device is limited by mechanical wear.

2.Piezo Optical Fiber Switch

The switch has a faster response speed, small in size and easy to integrate. It has strong resistance to environmental interference, no mechanical friction, and a long service life.

II. Application of Optical Fiber Switches

From the Laboratory to the Industrial Frontier

As a core component for optical signal path control, fiber optic switches are applied in multiple fields that require flexible scheduling of optical signals. They are particularly indispensable in applications such as optical communication, testing, and sensing where there are specific requirements for optical path reliability and switching speed.

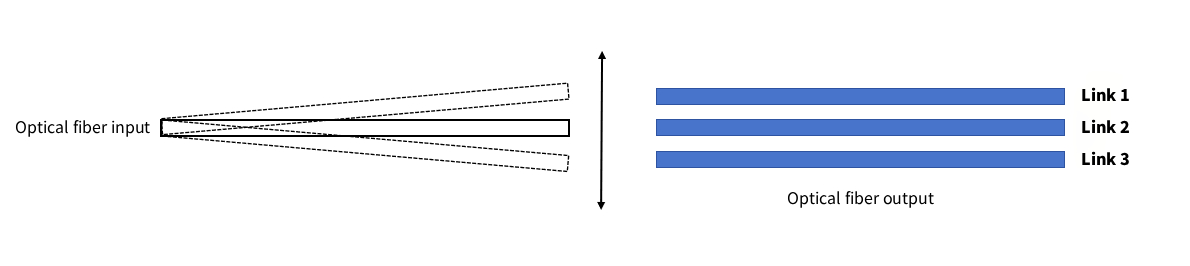

1.Optical Fiber Communication Network

The most core application field of optical fiber switches is the routing, protection and dynamic scheduling of optical signals, supporting the efficient operation of optical networks and optical interconnection in data centers. Optical fiber switches help achieve the switching between the primary and backup links. When the primary link is interrupted due to a fault, the switch can quickly switch to the backup link to ensure that communication is not interrupted. In large optical network nodes, cross-connection of multi-port optical signals is achieved through optical fiber switches, allowing for flexible scheduling of optical signals of different wavelengths or directions, etc.

(Note: Image from online resources)

2.Data Centers and Cloud Computing

Data centers are gradually building optical Internet to achieve high-speed data transmission, and optical fiber switches have become the key to high-density and high-bandwidth link scheduling. By switching different optical links through optical fiber switches, congestion on a single path can be avoided, data traffic can be balanced, and data transmission efficiency can be improved. The high-speed optical links within the data center need to be flexibly connected through optical fiber switches to support the dynamic networking and resource scheduling of servers and storage devices.

(Note: Image from online resources)

III. CoreMorrow Piezoelectric Nano-Positioning Technology

Performance Upgrade of Optical Fiber Switches

Among the numerous technical challenges of optical fiber switches, precise optical path alignment and positioning are the key factors determining performance. And this is precisely the area where piezoelectric nano-positioning technology comes into its own. Piezoelectric ceramic actuators can achieve nano-level positioning accuracy through a unique piezoelectric effect principle.

Core Advantages

1.

Ultra-fast response speed: The response time can be down to millisecond level

2.

High resolution: It can achieve sub-nanometer resolution and nanometer-level positioning accuracy

3.

Long service life: No mechanical friction or wear

The Application of Piezoelectric Nano-positioning Technology in Optical Fiber Switches can Bring about Significant Performance Improvements:

1.Reduce Insertion Loss

Through nanoscale position control, piezoelectric nanotechnology ensures that the optical fiber is in the optimal position, minimizing insertion loss.

2.Enhance the Switching Speed and Accuracy

The fast response of piezoelectric ceramic drivers enables fiber optic switches to achieve millisecond-level rapid switching while maintaining extremely high repeatability.

3.Enhance long-term stability

The extremely long service life of piezoelectric ceramics ensures that the fiber optic switch can perform billions of operations, significantly reducing maintenance requirements.

4.Expand the Adaptability of the Application Environment

The material and structural properties of piezoelectric nanotechnology enable it to operate stably in extreme environments such as high temperatures, vacuum, and strong magnetic fields, providing reliable solutions for special application scenarios such as aerospace and scientific experiments.

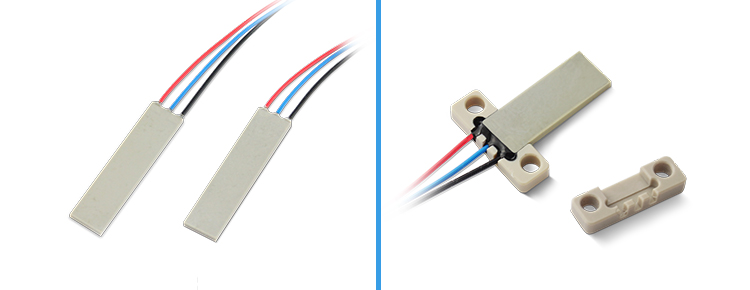

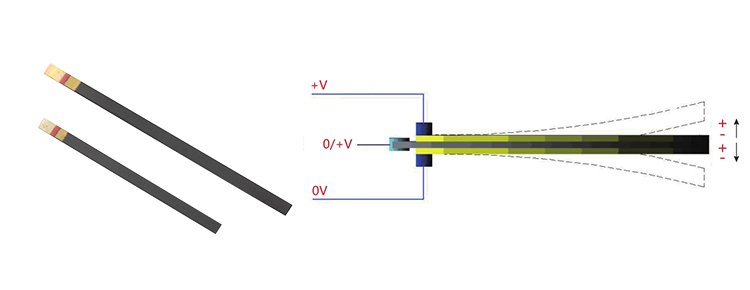

Piezoelectric nanotechnology is mainly applied in the key link of precise alignment of optical fiber end faces: in mobile optical fiber switches, piezoelectric ceramic bending plates are used to achieve bending displacement, helping to align the optical fiber end faces at the micro-nano level and minimizing connection losses to the greatest extent.

Square Piezo Benders

Fix one end of the piezo bender and drive it through a piezo controller. The other end of the piezo bender will swing up and down or in one direction.

An optional standard bonding or fixing device is available

Motion

Technical Data

|

Model |

NAC222X |

|---|---|

|

Length |

21mm/32mm/50mm/10mm |

|

Width |

7.8mm/5mm |

|

Height |

0.7mm/1.3mm/1.8mm |

|

Driving |

±100V或200V |

|

Stroke |

±27.5μm~±1490μm |

|

Resonant frequency |

130Hz~6900Hz |

|

Blocking force |

0.58N~10.4N |

|

Max. working temperature |

150℃ |

Double-Laminated Piezo Bender

Piezo benders utilize the inverse piezo effect of piezo ceramics to generate lateral displacement under the drive of an electric field. It adopts a double-laminated structure, with two layers of piezo ceramic plates arranged in the same polarization direction and closely bonded to the intermediate electrode layer. Under the drive of an alternating power supply, it generates the corresponding vibration amplitude and is applied to micro-displacement drive devices.

Technical Data

|

Voltage |

150V/200V |

|---|---|

|

Dimension |

60mm×20mm×0.7mm

49mm×2.3mm×0.8mm 35mm×2.1mm×0.7mm |

|

Active Length |

53mm/38mm/28mm |

|

Capacitance/Partition |

≈120nF/≈12nF/≈10nF |

|

Minimum unidirectional displacement |

2.6mm/1.5mm/1.4mm |

|

Min. blocking force |

0.5N/0.15N/0.14N |

Piezo Stacks

Low voltage piezo stacks have excellent performance and long service life, suitable for scientific experiments and industrial applications. Piezo stacks include both square and ring shape structures, with multiple sizes and displacements to meet the needs of different applications. Special insulation material ensures maximum output of dynamic performance under severe conditions. Ceramics are compact in size and easy to integrate.

characteristics

Sub-nanometer resolution

The max blocking force can be up to 50,000 N

Anti-magnetic field interference

Low power consumption

No wear

Vacuum compatible

Technical Data

|

Model |

Piezo Stacks |

|---|---|

|

Sectional dimension |

1.22mm×1.3mm~26mm×26mm |

|

Thickness |

1.7mm~20mm |

|

Stroke |

0.8μm~30μm |

|

Max stroke |

1μm~42μm |

|

Stiffness |

12N/μm~1282N/μm |

|

Resonant frequency |

30kHz~150kHz |

|

Blocking force |

80N~20000N |

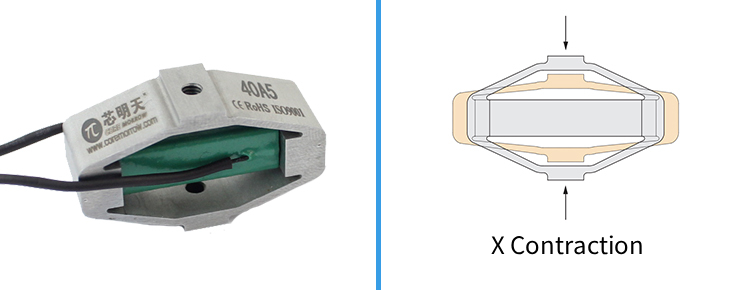

P06 Amplified Piezo Actuator

The amplified piezo actuator is an actuator that amplifies and outputs the displacement generated by low-voltage piezo stacks preloaded by a mechanical amplifying structure. The amplified structure is an mechanical shell, and its material is generally steel. In addition to providing optimized pre-tightening force for piezo stacks, it also protects piezo stacks from tensile forces that can cause irreversible or even fatal damage to piezo stacks. The mechanical amplified structure also provides the user with mechanical interface, easy to integrate.

characteristics

30μm to 1.9mm travel

Blocking force to 1000N

Unloaded resonant frequency to 3900Hz

Nanoscale resolution

Closed-loop available

Technical Data

|

Model |

P06 |

|---|---|

|

Stroke |

30μm~1900μm |

|

Unloaded resonant frequency |

125Hz~3900Hz |

|

Blocking force |

3.6N~1000N |

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.