CoreMorrow PZT Piezo Ceramics and Stacks

Types, Characteristics and Applications of CoreMorrow PZT Piezo Ceramics

1.

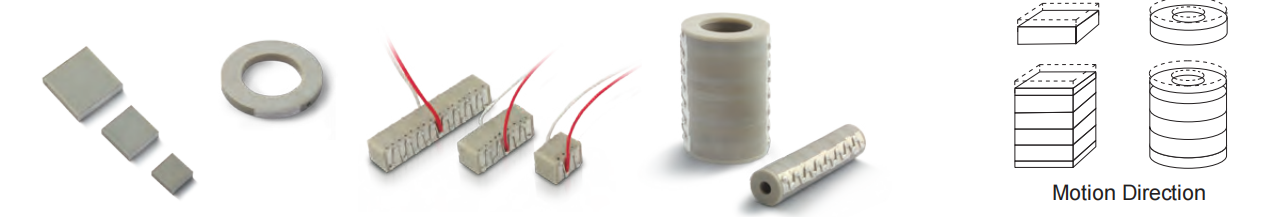

Low Voltage Piezo Stacks

Low voltage piezo stacks have excellent performance and long service life, suitable for scientific experiments and industrial applications. Piezo stacks include both square and ring shape structures, with multiple sizes and displacements to meet the needs of different applications. Special insulation material ensures maximum output of dynamic performance under severe conditions. piezo stacks are compact and easy to integrate.

Characteristics

Square stack and ring stack structure

Driving voltage 0~150V

Max. displacement up to 50μm

Blovking force up to 20000N

Long service life

Small size, easy to integrate

Vacuum and low temperature version available

Custom version available

Applications

Laser cavity tuning

Precision positioning

Piezo dispensing valve

Fiber stretching

Active vibration control

Phase shifter/phase modulator

Piezo deformable mirror

2.

High Voltage Piezo Stack

Characteristics

Square stack and ring stack structure

Exellent dynamics

Driving voltage 0~500V/1000V

Max. displacement up to 130μm

Blocking force up to 50000N

0~0.5mm monolayer thickness

100nF/cm³ El. capacitance

CTE +2ppm/°C

Custom version available

Applications

Nanopositioning

Active vibration control

Vibration isolation platform

Semiconductor processing test

Optical adjustment

Cavity tuning

Shock Wave

Large load applications, etc

3.

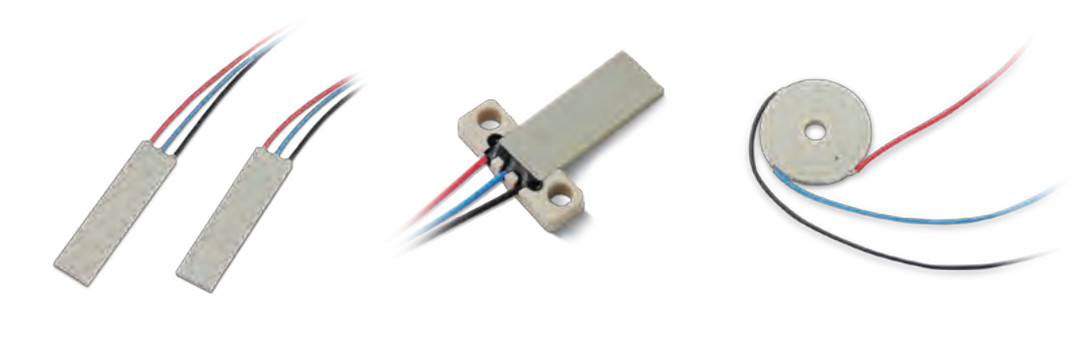

Low Voltage Piezo Plate/Ring Actuator/Stack

Sheet-shaped piezoelectric ceramics are square or ring sheets with a standard thickness of 2mm. The maximum displacement of a single chip can reach 3.3 μm. The material is PZT5A.

Stacked piezoelectric ceramics are used after stacking multiple piezoelectric ceramic sheets and welding common electrodes. The height is freely selected. The displacement after stacking is the total displacement of each sheet, and the maximum can reach 326.7μm. Customized UHV version, withstand voltage up to 10-10torr=1.33×10-10mbar.

Characteristics

Square plate, ring plate or square stack , ring stack

Driving voltage 0~60V/150V/200V

Stack displacement up to 326.7μm

Blocking force up to 9450N

Operating temperature up to 200°C

Custom version available

Applications

Nanopositioning

Active vibration control

Semiconductor processing test

Optical adjustment

Cavity tuning

Fiber stretching

Piezo dispensing valve, etc

4.

Piezo Bender

Characteristics

Square plate and ring plate available

Unidirectional or bidirectional bending motion

Unipolar and bipolar control modes

Driving voltage ±100V or 200V

Max. displacement up to ±1490μm

Resonant frequency up to 6900Hz

Max. operating temperature 150°C

Custom version available

Applications

Beam deflection

Semiconductor technology

Active damping

Liquidometer

Optical fiber scanning

Optical fiber cutting

5.

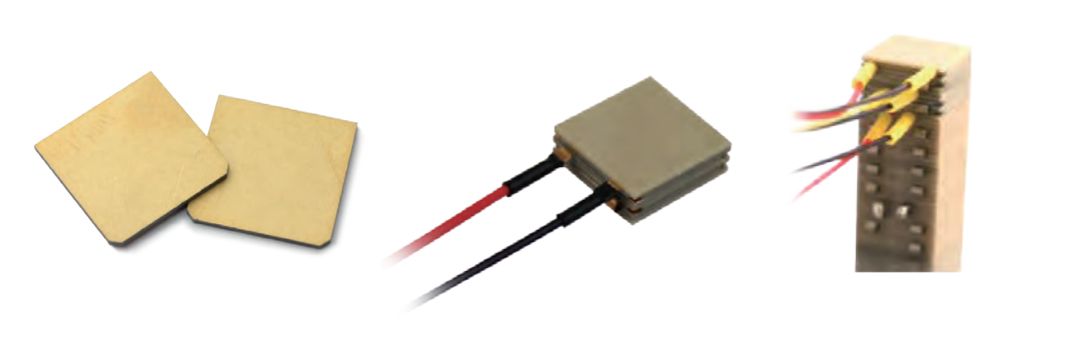

Piezo Shear Actuator/Stack

Characteristics

Bipolar use

Driving voltage ±320V

Shear motion

Single shear displacement up to 1.5μm

Resonant frequency up to 1750kHz

Can be stacked into large displacement or XYZ 3 axes, single-axis stroke up to 6 µm

Custom version available

Applications

Fiber optic adjustment

Fiber end detection

Precise positioning

Cavity tuning

Piezo motor, etc.

6.

Ultrasonic/Monolayer Piezo Ceramic

Characteristics

Square plate, round plate, circular plate and tube available

Driving voltage up to 1kV/mm

Nanoscale displacement

Resonant frequency range 100k~6.6MHz

Low electrostatic capacity

Custom version available

Applications

Ultrasonic vibration

Sensor

Transducer

Ultrasonic cleaning

Medical imaging

NDT non-destructive testing, etc

7.

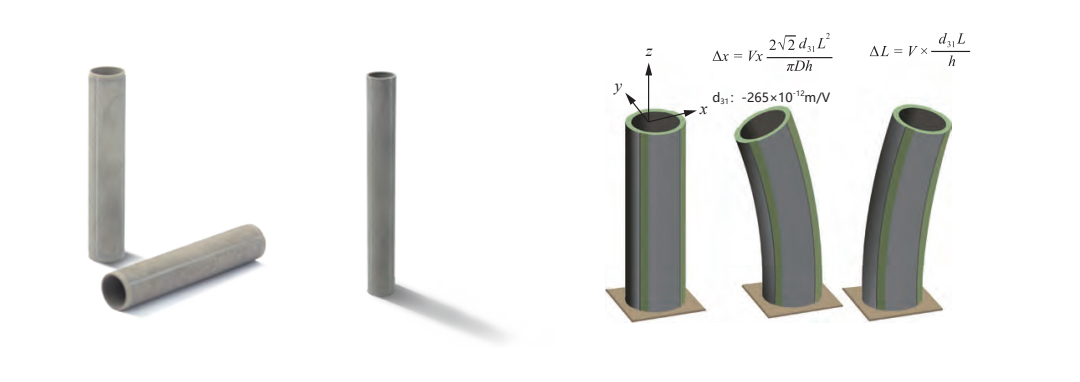

Piezo Tube Scanners

Characteristics

Piezo tube

Driving voltage is ±264V

Scanning range up to 114μm

Z-displacement up to 12μm

Can be used in low temperature and vacuum environment

Custom version available

Applications

Scanning probe

Microscope

Fiber stretching

Beam scanning

Optical fiber scanning, etc.

8.

Piezo Ceramic Fibers

Characteristics

Outer diameter 105μm, 250μm, 800μm, customizable

Typical length is 75mm and 150mm

PZT5A SP505(Navy type II) available

Provided not poled and not electroded

Applications

Acoustic sensor

Microbrake

Flowmeter, etc.

9.

Ultrasonic Composites

Characteristics

Three types: Dice & Fill, 1-3 Random Fiber, 1-3 Regular Fiber

Size can be up to 10cm×10cm, larger or curved type can be customized

Frequency 80kHz~15MHz

Fill factor range is 15%~80%

Gold, copper-tin electrode available

Operating temperature 95°C, can be customized 130°C

Applications

NDT non-destructive testing

Medical ultrasound

Flow control and measurement

Phased array transducer

SONAR single element transducer

General underwater ultrasound applications

Air ultrasonic transducer

10.

MFC Macro Fiber Composite

The Macro Fiber Composite (MFC) is the leading low-profile actuator and sensor offering high performance, flexibility and reliability in a cost-competitive device. Since then, the MFC has been continuously improved and customized to fit customers' specific needs and to meet the requirements for new applications.

As actuators, MFC's displacement is up to several hundreds micrometer, blocking force up to 693N. As sensors, charge quantity generated is related to vibration amplitude, frequency, etc. Output voltage is up to several volts, even 10V, 20V or higher. Output current is μA level.

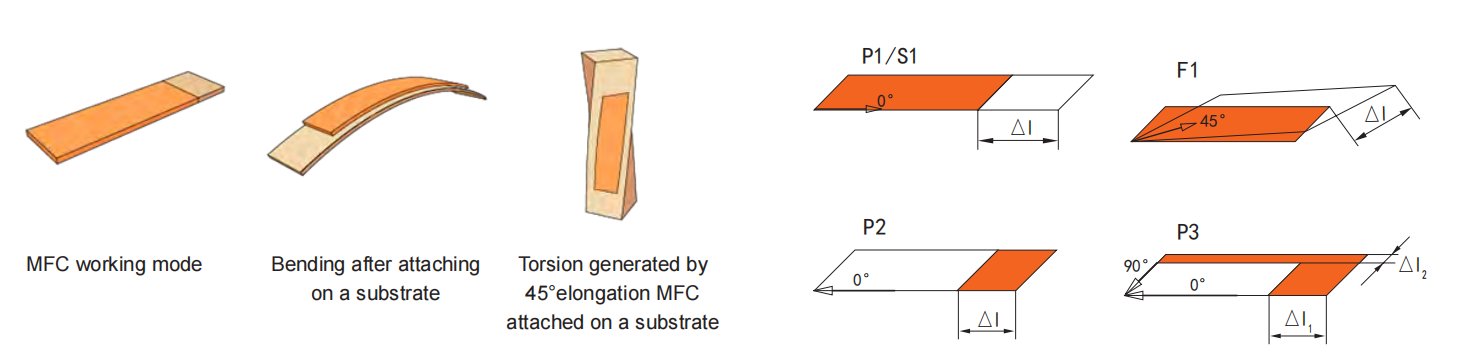

MFC Working Mode

MFC Working ModeCharacteristics

Driving voltage is -500V~1500V

Maximum displacement can be up to 147μm

Flexible, durable and reliable

Directional actuation and sensing

Damage-tolerant

Conforms to surfaces

Readily embeddable

Environmentally sealed package

Increased strain actuator efficiency

Available as elongator (d33 mode) and contractor (d31 mode)

Material: PZT5A, oiptional PMN-PT, PZN-PT available

Custom version available

Applications

Vibration control of cantilever beam

Radar antenna

Vibration-power Generating

Bionics

De-Icing of composite airplane wings and structures

- Previous article:S51 Piezo Tip/Tilt Stage Applied to Tuning Wafer Posture

- Next article:Ultrasonic Resonance Driven Linear and 360°Rotation Piezo Motor