- Introduction

- Feedback

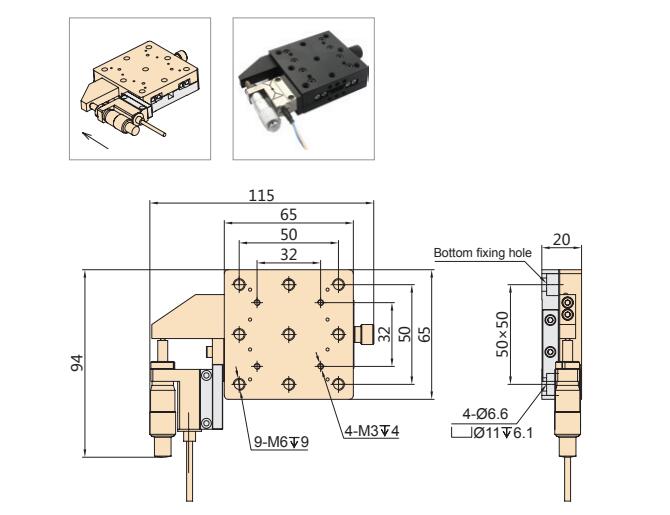

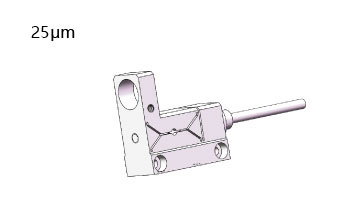

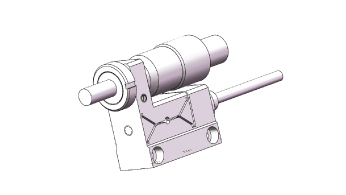

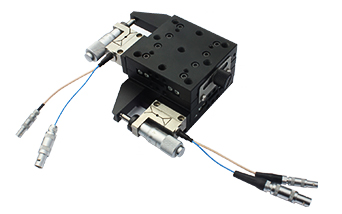

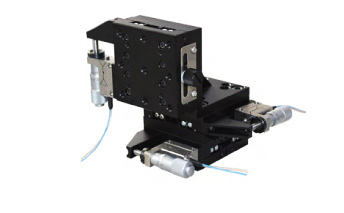

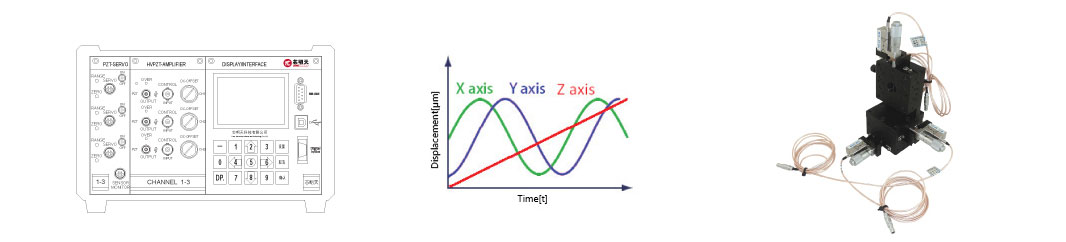

Macro micro composite piezoelectric platform is to point to in the micrometer integration on the basis of the piezo positioning platform, hand the micrometer can be 13 mm stroke of macro regulation, piezoelectric movement platform can be 25 microns stroke of nanoscale micro adjustment, and micrometer adjustment accuracy on the platform of piezoelectric motor adjustment range, so as to ensure the precision of adjustment and convenient.

Characteristics

|

|

|

|

|

|

|

|

Macro-Micro Composition

Macro-micro composition is to complete the large-scale precision positioning requirements through macro adjustment micrometer head and piezoelectric micro-motion adjustment mechanism.

|

Piezo driving

|

Manual adjustment

|

Macro-Micro Composition

|

|

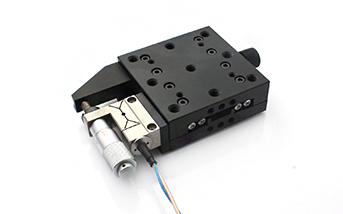

1 Axes Large Displacement Linear Stage

|

2 Axes Large Displacement Linear Stage

|

3 Axes Large Displacement Linear Stage

|

|

Driving and Controlling

|

Applications

|

|

|

|

|

| Technical data | ||||

|

Model |

S-Closed loop |

P83SX65 |

P83KX65 |

Units |

|

K-Open loop |

||||

|

Active axes |

X |

X |

|

|

|

Travel range |

13mm+25μm |

13mm+25μm |

mm+μm |

|

|

Material |

Steel |

Steel |

|

|

|

Manual Adjustment travel range |

13 |

13 |

mm |

|

|

Manual Adjustment resolution |

10 |

10 |

μm |

|

|

Driving mode |

Screw thread pair |

Screw thread pair |

|

|

|

Sensitivity |

<2 |

<2 |

μm |

|

|

Least count |

10 |

10 |

μm |

|

|

Screw pitch |

0.5 |

0.5 |

mm/rev. |

|

|

Piezo adjustment travel range |

0~120 V |

20 |

20 |

μm±20% |

|

0~150 V |

25 |

25 |

μm±20% |

|

|

Sensor |

SGS |

- |

|

|

|

Min step(resolution) |

1 |

0.5 |

nm, typ. |

|

|

Closed-loop linearity |

0.2 |

- |

%F.S. |

|

|

Repeatability |

0.1 |

- |

%F.S. |

|

|

Push force capacity |

20 |

20 |

N |

|

|

Stiffness |

2 |

2 |

N/μm±20% |

|

|

Load(Z axis) |

1.5 |

1.5 |

Kg |

|

|

Mass |

400 |

400 |

g |

|

|

Operating temperature[1] |

-20~80 |

-20~80 |

°C |

|

|

Electrical capacitance |

1.8 |

1.8 |

μF±20% |

|

|

Cable[2] |

1.5 |

1.5 |

m±10mm |

|

|

Connector[2] |

LEMO |

LEMO |

||

Note: Max driving voltage could be -20V~150V, recommended voltage 0~120V for long-term and high-reliable operation to extend lifetime. Technical data is measured by CoreMorrow E00/E01 series piezo controller.

[1] Custom ultralow temperature and ultrahigh vacuum versions are available.

[2] Custom cable length and connector is available.

Note: The parameters mentioned above are related to the test environment and test equipment.

|

|

|||||||||||||||

|