- Introduction

- Feedback

Characteristics

|

|

|

|

|

Applications

|

|

|

|

|

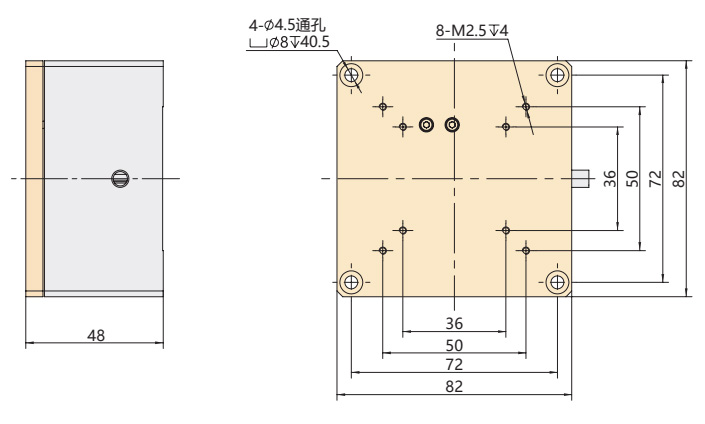

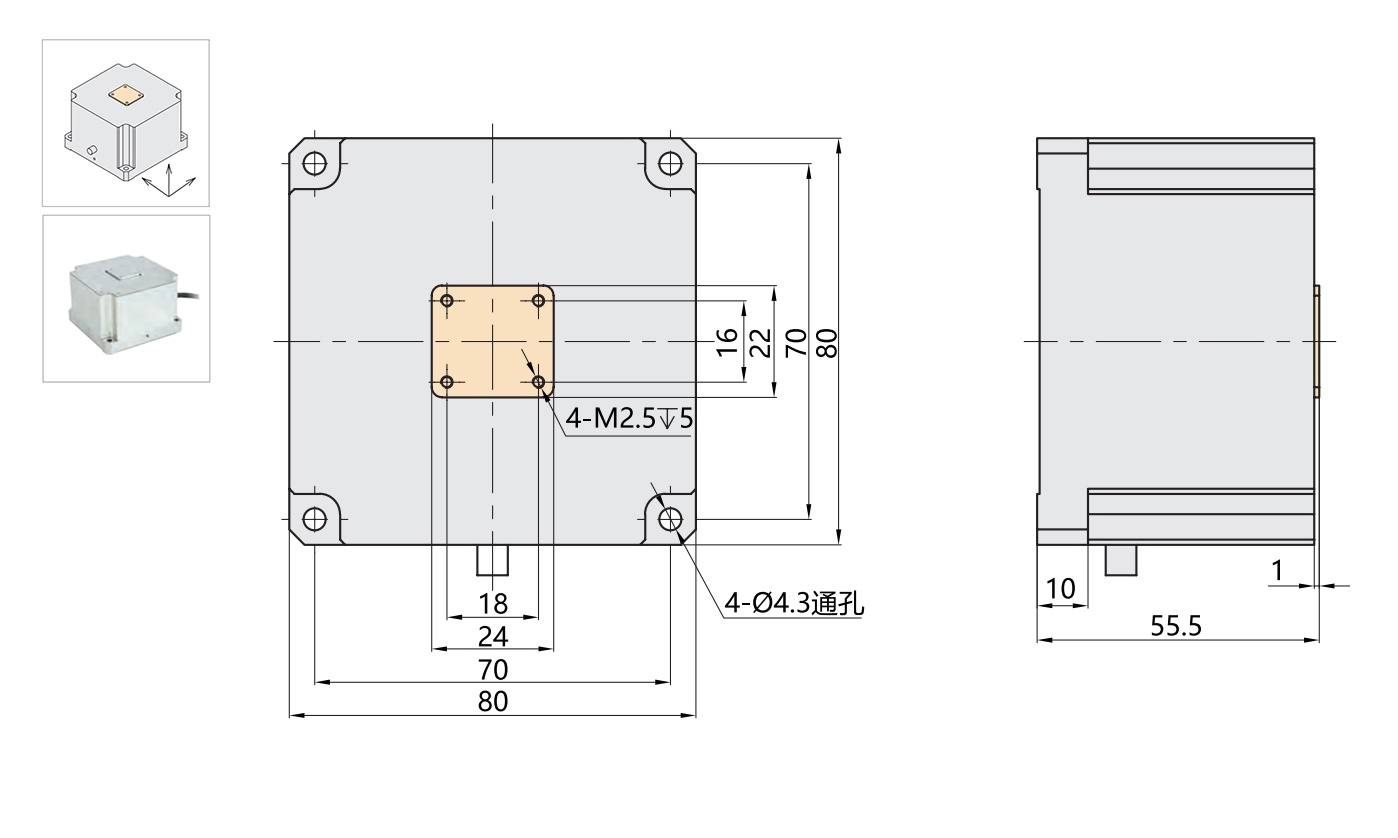

| Technical Data | ||||

|

Type |

S-Closed loop |

P66.XZ100Y30S |

P66.XZ100Y30K |

Units |

|

Active axes |

X、Y、Z |

X、Y、Z |

|

|

|

Drive control |

3 driving channels

3 sensing channels

|

3 driving channels |

|

|

|

Nominal travel range(0~120V) |

X100/Y28/Z85 |

X100/Y28/Z85 |

µm±10% |

|

|

Max. travel range(0~150V) |

X125/Y35/Z105 |

X125/Y35/Z105 |

µm±10% |

|

|

Sensor type |

SGS |

- |

|

|

|

Resolution |

XZ4/Y1.2 |

XZ1.5/Y0.5 |

nm |

|

|

Linearity |

X0.036/Y0.019/Z0.15 |

- |

%F.S. |

|

|

Repeatability |

X0.017/Y0.022/Z0.165 |

- |

%F.S. |

|

|

Pitch/yaw/roll |

XY<5,Z<25 |

XY<5,Z<25 |

μrad |

|

|

Unloaded resonant frequency |

X270/Y475/Z560 |

X270/Y475/Z560 |

Hz±20% |

|

|

Resonant frequency@300g(vertical mounting) |

X140/Y230/Z400 |

X140/Y230/Z400 |

Hz±20% |

|

|

Load capacity

|

Horizontal |

1 |

1 |

kg |

|

Vertical |

0.5 | 0.5 | ||

|

Inverted |

0.5 | 0.5 | ||

|

Step time |

XZ40/Y10@300g |

XZ15/Y5 |

ms±20% |

|

|

El.capacitance |

XY7/Z14 |

XY7/Z14 |

μF±20% |

|

|

Operating temperature |

-20~65 |

-20~65 |

℃ |

|

|

Material |

Stainless steel, aluminum alloy |

Stainless steel, aluminum alloy |

|

|

| Mass | 800 | 800 |

g±5% |

|

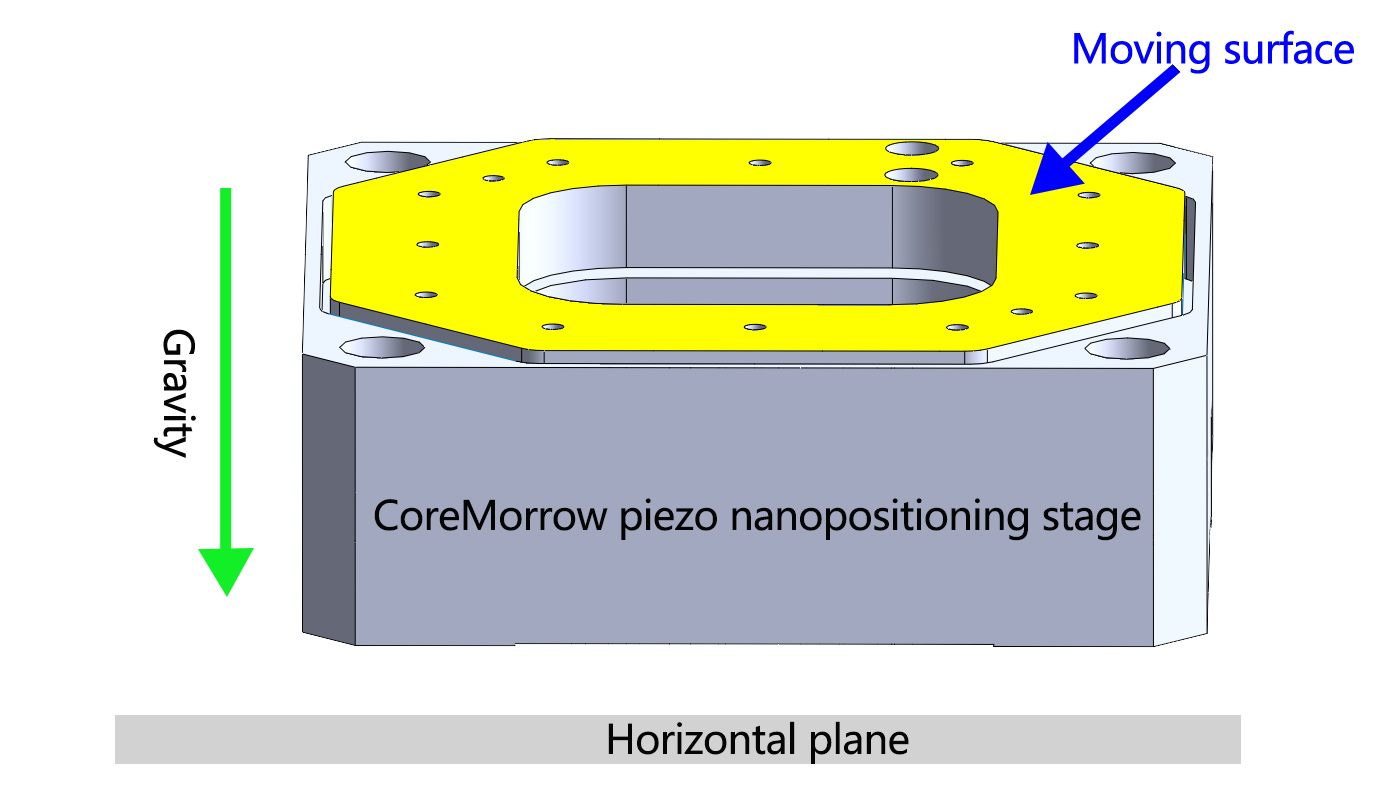

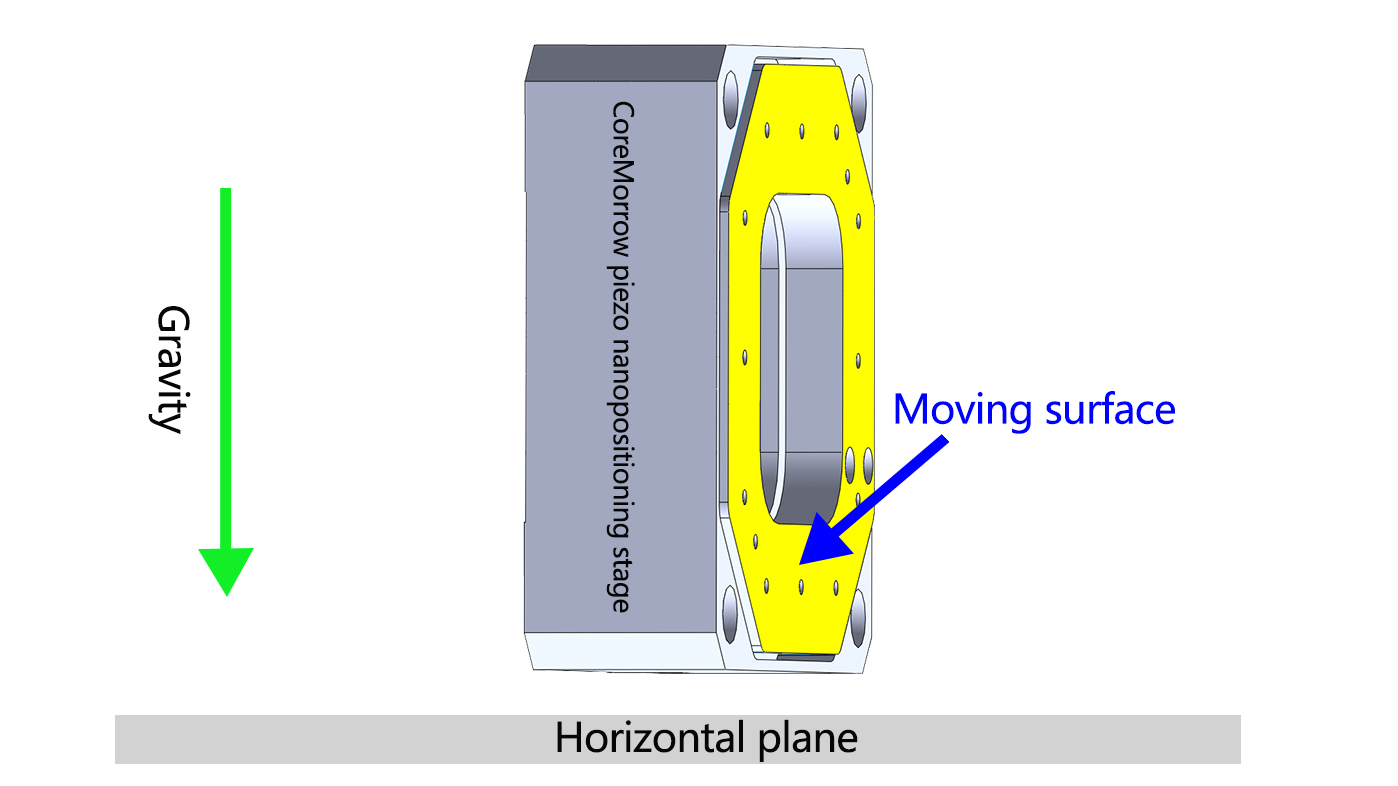

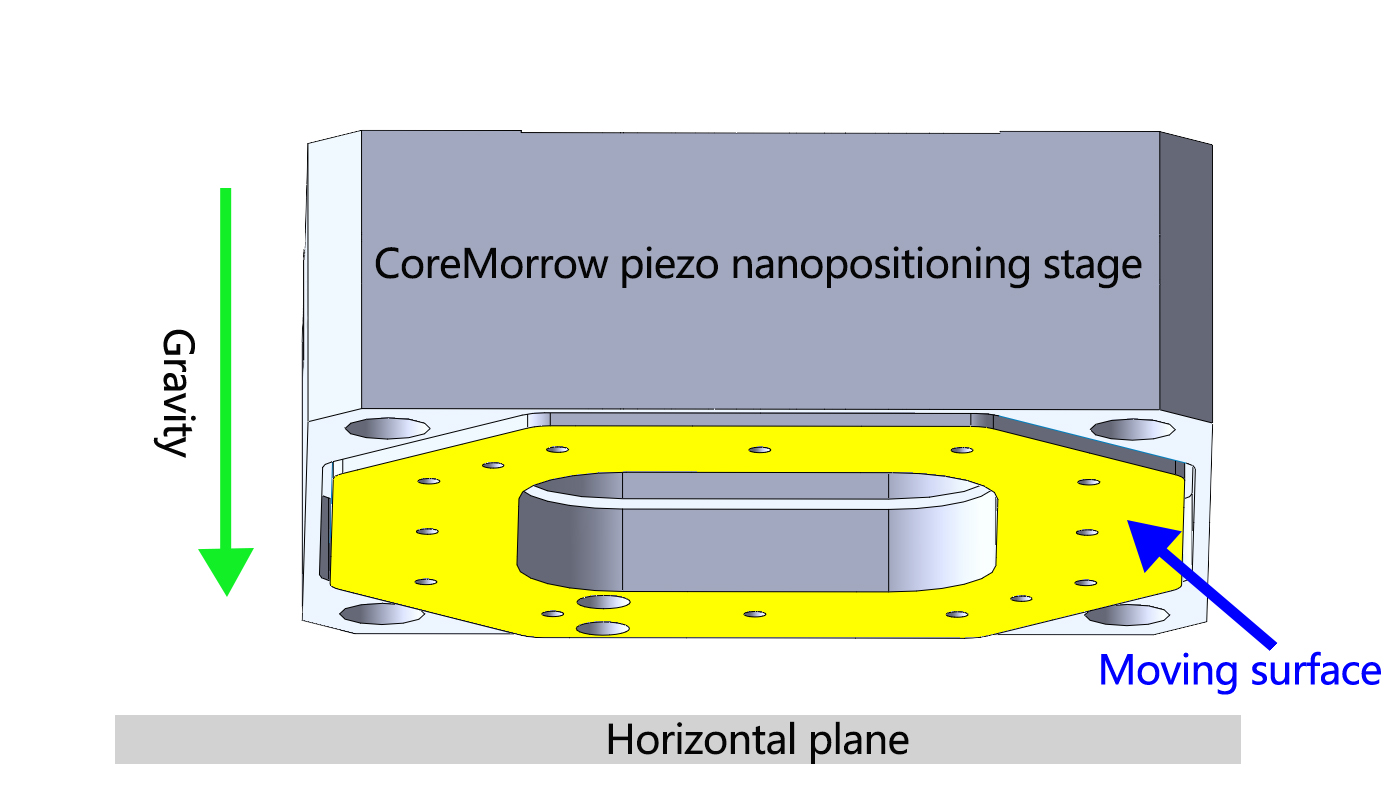

| Mounting Method |

Horizontal Mounting |

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

|

|

||||||||||||