- Introduction

- Feedback

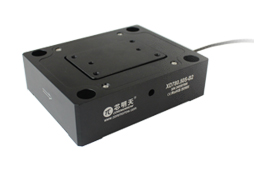

XD780 is an X-axis piezo nanopositioning stage, with 50μm, 150μm or 200μm travel. It adopts a no-friction flexible hinge guiding mechanism and integrated structural design. It is equipped with high-performance piezo actuators to ensure 200μm displacement. The closed-loop version has a full bridge design which avoids temperature drift and ensures that the positioning accuracy is nanoscale.

Characteristics

|

|

|

|

|

|

|

|

|

|

|

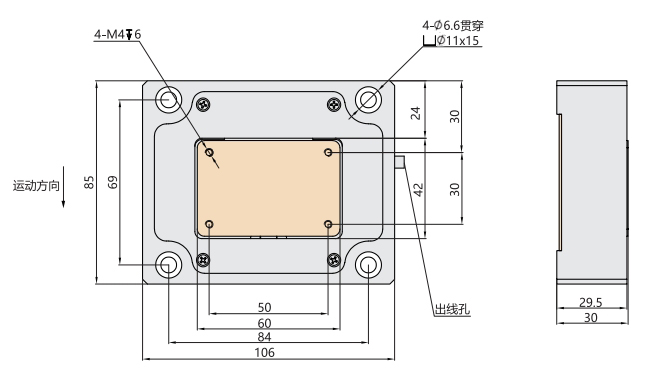

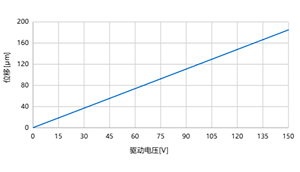

XD780.50

|

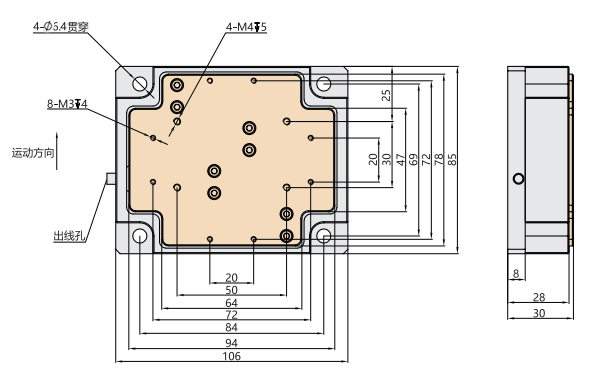

XD780.150/200

|

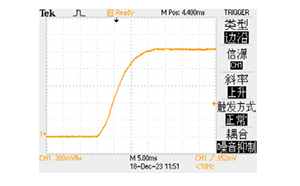

Loaded Step Time XD780.50S loading 5kg(1V), the step time is about 15ms.

|

|

Closed-Loop Curve-XD780.150S

|

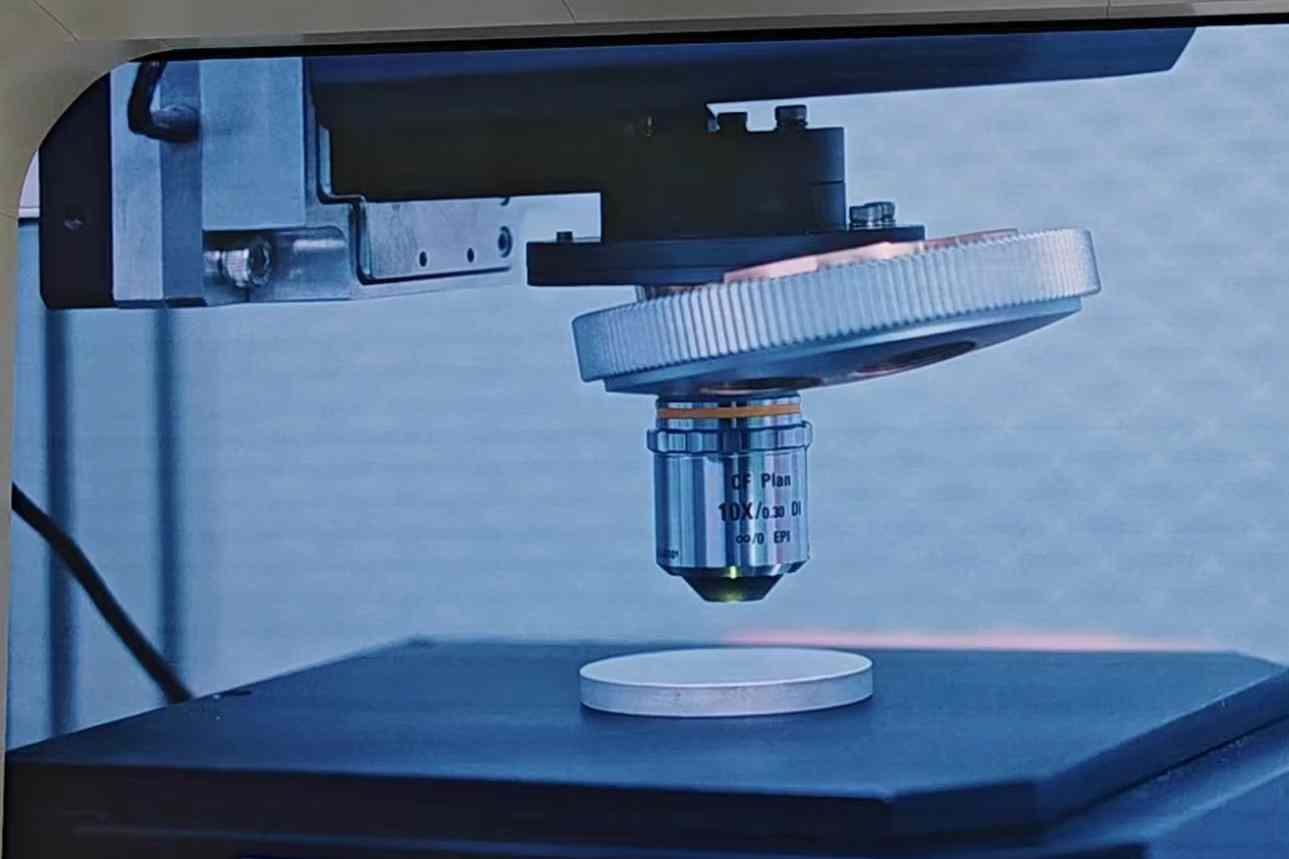

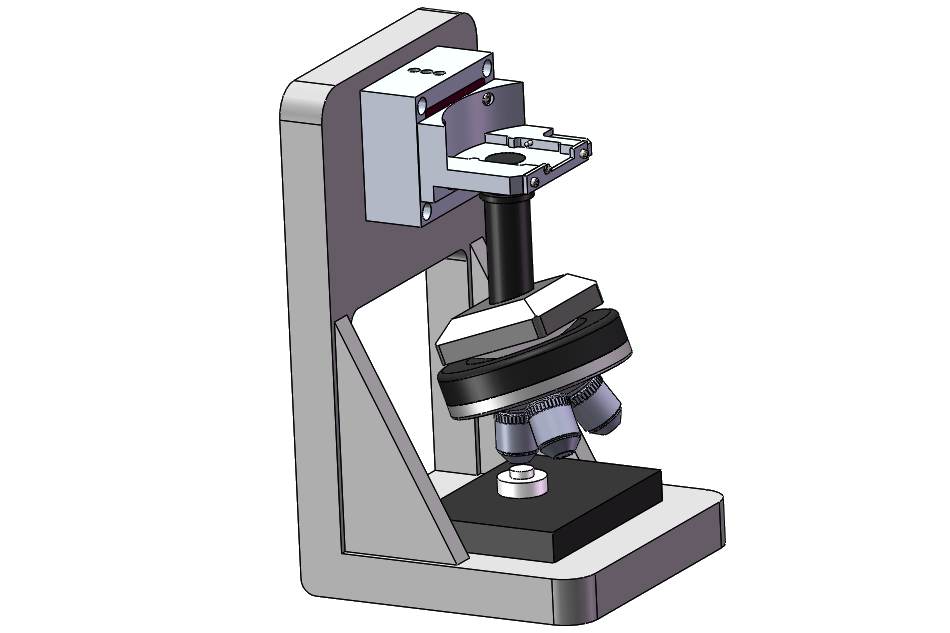

Z-direction multi head objective focusing

|

Z-direction multi head objective focusing

|

Application

|

|

|

|

|

|

|

|

|

|

| Technical Data | |||||

|

Type |

S-Closed loop |

XD780.50S |

XD780.150S |

XD780.200S |

Units |

|

Active axes |

X |

X |

X |

|

|

|

Drive control |

1 driving channel, 1 sensing channel |

|

|||

|

Nominal travel range(0~120V) |

40 |

120 |

160 |

μm±10% |

|

|

Max.travel range(0~150V) |

50 |

150 |

200 |

μm±10% |

|

|

Mechanism |

Direct Drive |

Amplified Drive |

Amplified Drive |

|

|

|

Sensor type |

SGS/- |

SGS/- |

SGS/- |

|

|

|

Resolution |

2/0.5 |

5/1.5 |

7/2 |

nm |

|

|

Linearity |

0.01/- |

0.03/- |

0.05/- |

%F.S. |

|

|

Repeatability |

0.02/- |

0.01/- |

0.02/- |

%F.S. |

|

|

Load capacity |

Horizontal |

5 |

5 |

5 |

kg |

|

Vertical |

0.05 or 5 |

0.05 or 5 |

0.05 or 5 |

||

|

Inverted |

5 |

5 |

5 |

||

|

Unloaded resonant frequency |

2200 |

760 |

700 |

Hz±20% |

|

|

Resonant frequency@5kg |

160 |

100 |

85 |

Hz±20% |

|

|

Step time |

15@5kg(1V)/7.5 |

30/4 |

50@5kg(1V)/10 |

ms±20% |

|

|

El. capacitance |

10.2 |

27.2 |

27.2 |

μF±20% |

|

|

Material |

Steel, Al |

Steel, Al |

Steel, Al |

|

|

|

Mass(Cable included) |

450 |

1000 |

<1051 |

g±5% |

|

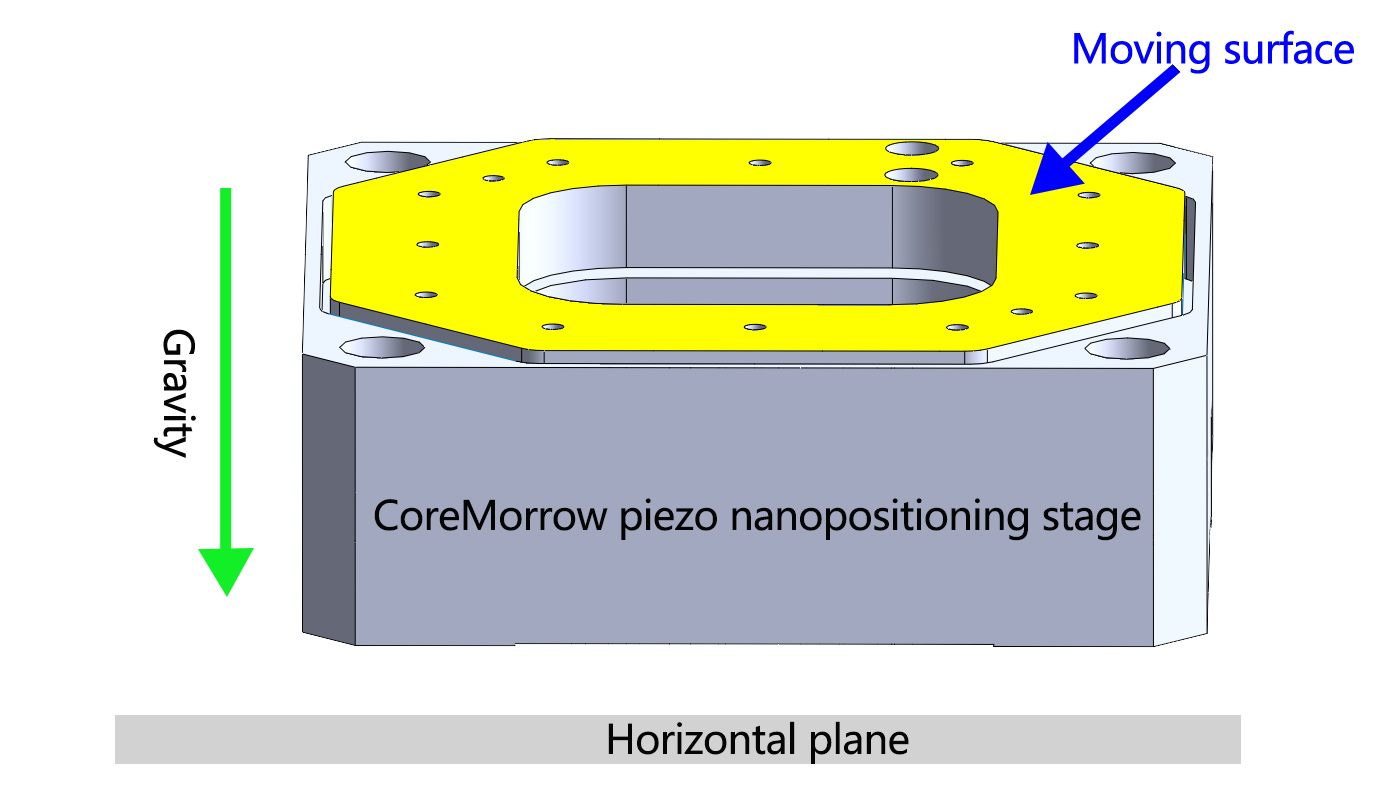

| Mounting Method |

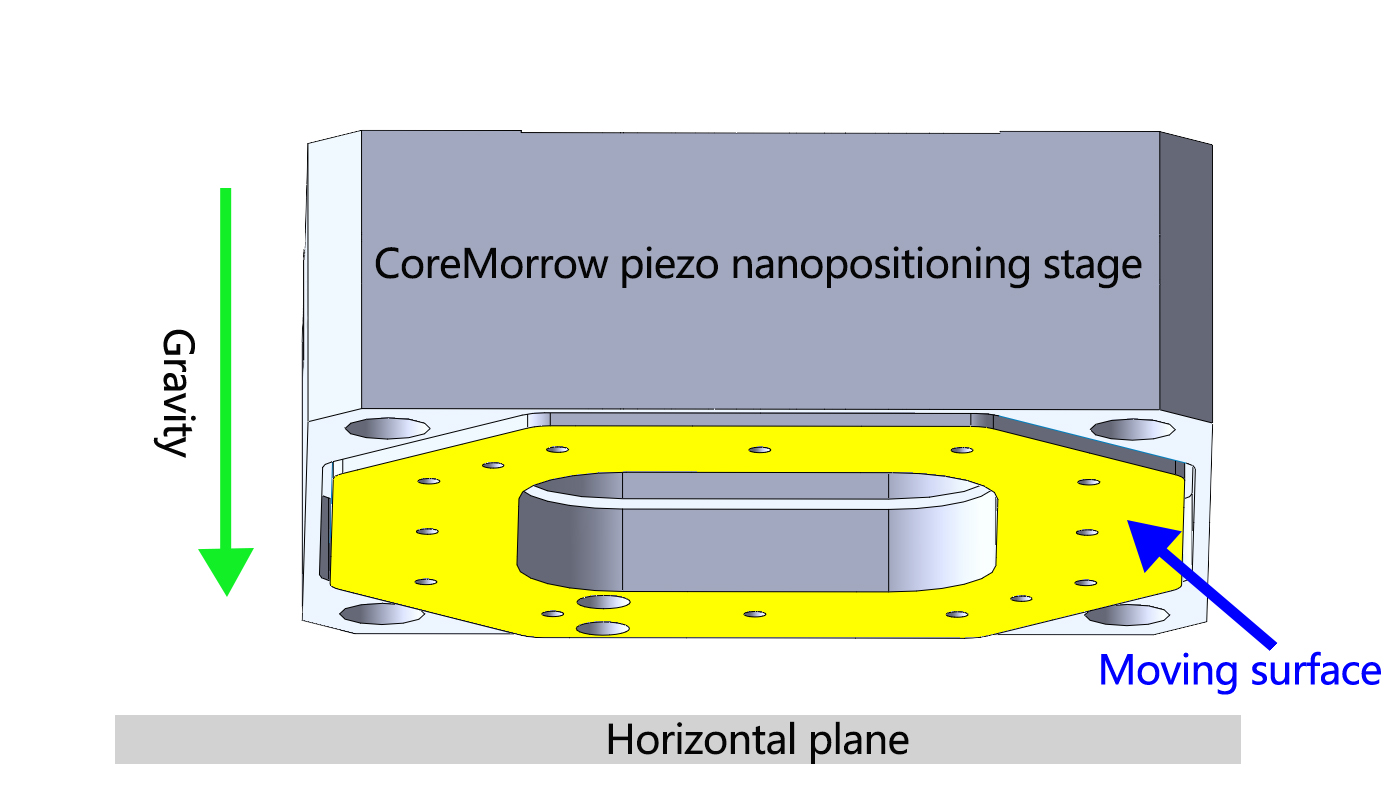

Horizontal Mounting |

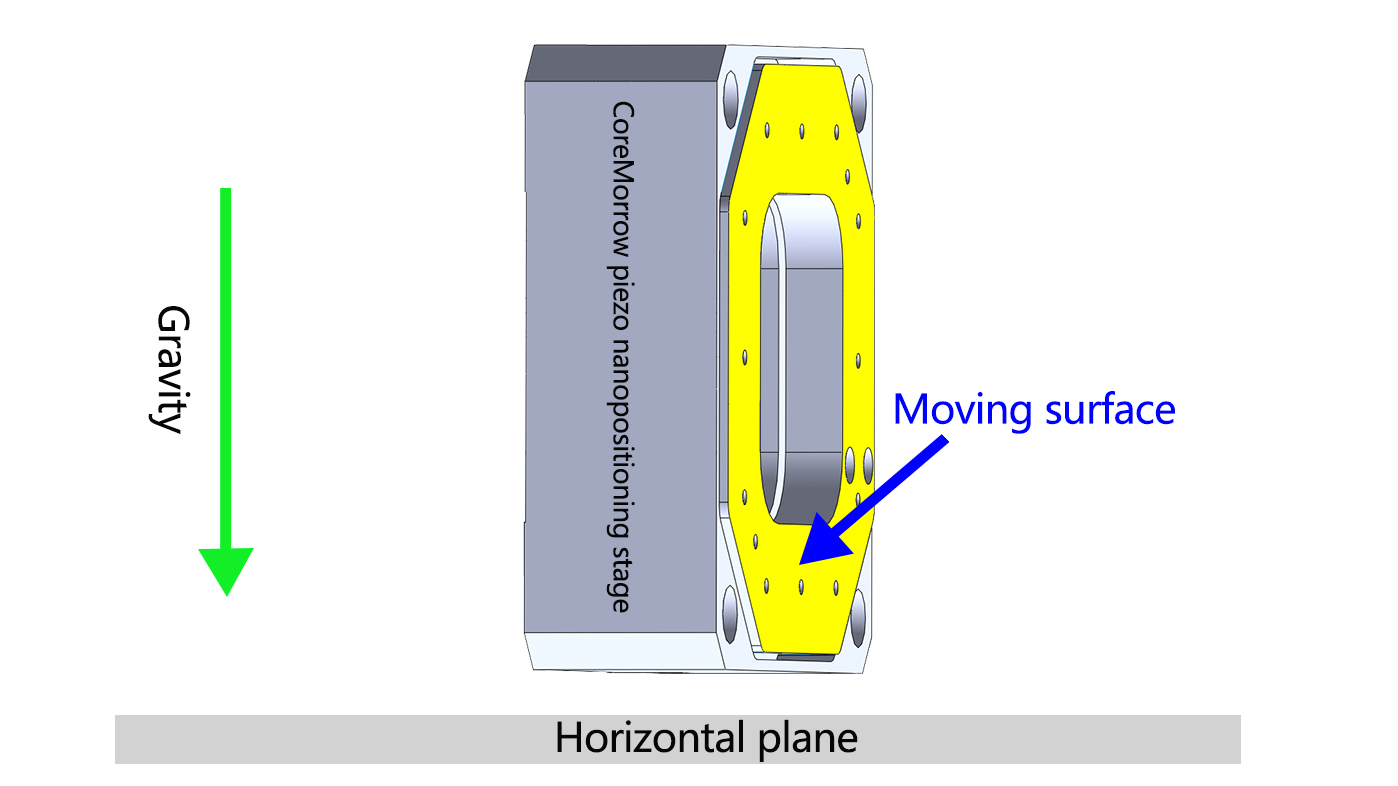

Vertical Mounting |

Inverted Mounting |

| Definition |

Place the PZT platform horizontally for installation, with the moving surface located above the PZT platform and parallel to the horizontal plane.

PS: Default direction for carrying capacity in the parameter table

|

Place and install the PZT platform vertically, with the moving surface parallel to the direction of gravity

|

Place the PZT platform horizontally, but the moving surface is located below the PZT platform |

| Diagram |

|

|

|

| Note |

When the mounting method is selected as vertical mounting, pay attention to the outlet port |

||

|

|

|

||||||||||||||||