P33S2T25 Macro-Micro Piezo Steering Stage: Dynamic Optical Path Compensation

In precision optical experiments and industrial applications, the stability of the beam is a key factor in ensuring the performance of the system. However, environmental vibration, thermal drift of the system, and other uncontrollable mechanical disturbances often cause the optical path to shift, affecting imaging quality, processing accuracy, or measurement precision. Traditional solutions may require complex multi-level adjustment mechanisms or have difficulty balancing the adjustment range and fine-tuning accuracy. P33S2T25 macro and micro composite piezo fast steering mirror is an integrated component of a piezo tip/tilt stage and a hand-adjustable optical mount, simplifying the adjustment process required for optical path compensation applications.

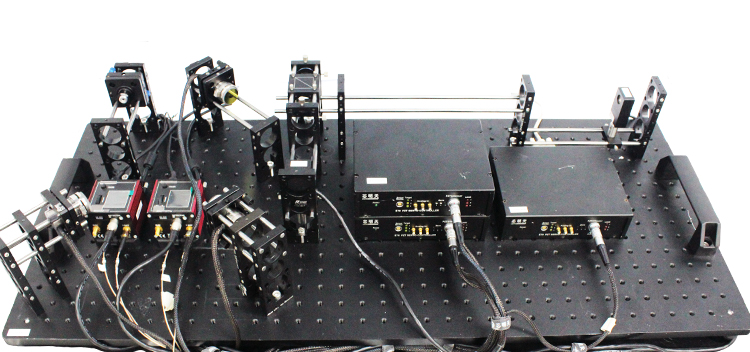

I.P33S2T25 Macro-Micro Composite Piezo Fast Steering Stage

The Combination of Coarse and Fine Tones

The design core of P33S2T25 lies in integrating two different precision adjustment mechanisms into a compact unit:

1.Manual coarse adjustment frame: It provides a deflection range of ±6° per axis to achieve initial alignment of the optical path and large-scale static deviation compensation. Its highly rigid mechanical structure provides a stable foundation for subsequent fine adjustment.

2.Piezo tip/tilt stage: Based on manual setting, it offers a deflection range of 3.5mrad per axis, featuring micro-radian resolution and millisecond-level response speed. This part is responsible for compensating the rapid jitter and slow drift of the optical path in real time and dynamically.

This integrated design enables users to avoid separately installing and calibrating the common adjustment frame and the independent piezo steering mirror in the system, simplifying the complexity of system integration.

II.P33S2T25 Macro-Micro Composite Piezo Fast Steering Stage

How to Achieve Optical Path Compensation

P33S2T25 Macro-micro composite piezo fast steering stage provides an efficient, compact and fast platform for dynamic optical path compensation by combining macroscopic manual adjustment with microscopic piezo drive. It is particularly suitable for applications that require both initial flexible alignment and high-precision real-time suppression of dynamic disturbances, providing a practical engineering solution for enhancing the anti-interference capability and long-term stability of optical systems.

1.Static Pre-Adjustment and Long-Term Drift Compensation

When the optical path slowly drifts due to system startup or changes in ambient temperature, the manual coarse adjustment mechanism can be used for re-alignment to actively compensate for larger static deviations and ensure that the beam remains within the effective working range.

2.Dynamic Real-Time Vibration Compensation

When the system is disturbed by external vibration or other factors, the piezo deflection mirror is driven to precisely deflect the lens at an angle, thereby compensating for the beam in the opposite direction along its propagation path.

III. P33S2T25 Macro-Micro Composite Piezo Fast Steering Stage

Core Applications

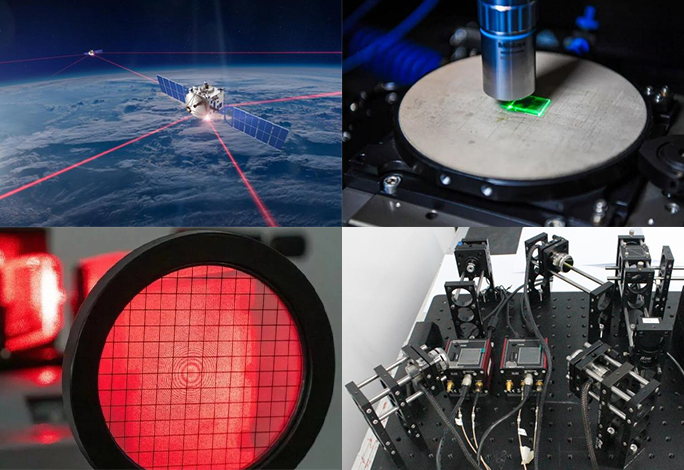

The high resonant frequency of the P33S2T25 macro and micro composite piezo fast steering stage enables it to effectively compensate for vibration interference ranging from hundreds of Hz to thousands of Hz, and it has a fast response speed, allowing multiple adjustments to be completed in a short time. The micro-arc resolution also ensures that the final beam pointing has high precision. In addition, the integrated structure reduces mechanical clearance and nonlinear factors in the control process, which is conducive to improving the control accuracy of the closed-loop system.

Based on the dual capabilities of static alignment and dynamic rapid deflection of the P33S2T25, it has application potential in multiple fields that require precise beam control:

1.Laser communication: Compensate for the beam pointing deviation caused by platform vibration and other factors to maintain a stable communication link.

2.Interferometry system: It is used to stabilize the optical path of the laser interferometer, compensate for angular drift caused by environmental disturbances, and ensure the stability of the interference fringes.

3.Laser direct writing: During long-term processing, it compensates for the slow drift of the optical path to ensure the positioning accuracy of the processed pattern and the consistency of feature dimensions.

4.Modular integration: By increasing holes, it can be integrated as a functional module into a cage structure, ensuring the coaxial optical path and enabling rapid and stable compensation for multi-optical path systems, significantly enhancing the efficiency and structural rigidity of high-precision optical system construction.

Note: Image from online resources

Technical Data

|

Model |

P33S2T25 |

|

Active axis |

θx、θy |

|

Manually adjust the deflection stroke |

12° |

|

Active axis |

θx、θy |

|

Drive Control |

3 driving channels, 2 sensing channels |

|

Nominal tilt angle(0~120V) |

2.8mrad/axis(≈578”) |

|

Max. tilt angle(0~150V) |

3.5mrad/axis(≈722”) |

|

Sensor |

SGS |

|

Resolution |

0.05μrad(≈0.01”) |

|

Linearity |

θx0.06%F.S./θy0.09%F.S. |

|

Repeatability |

θx0.08%F.S./θy0.06%F.S. |

|

Unloaded resonant frequency |

θx2700Hz/θy4700Hz |

|

Resonant frequency@36g |

θx1780Hz/θy1850Hz |

|

Step time |

5ms@36g |

|

El.capacitance |

3.6μF/axis |

|

Cable length |

1.5m |

|

Material |

Steel, Al |

|

Mass(including cable) |

300g(including cable) |

Recommended Controller

E70.D3S-H multi-channel piezo controller is a small-sized, high-power, low-power consumption, high-bandwidth, and low-ripple noise 3-channel piezo controller. This controller is powered by DC24V, integrates digital and analog control functions, optional open/closed loop, RS-232/RS-422/USB communication interfaces. It features an integrated PZT&Sensor mini interface for easy connection, and external control functions can be set, which makes the operation very simple and convenient.

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.