The Precision Code of Piezoelectric Nano Phase Shifter -Laser Interferometer

As the demand for accuracy has reached the nanometer level, in the field of precision manufacturing, whether it is scientific research breakthroughs in laboratories or high-precision and cutting-edge production in industrial manufacturing, laser interferometers, as the core technology of precision measurement, have become an indispensable precision coordinate system in these fields due to their advantages of high precision, high sensitivity and large measurement range. It can measure the surface flatness of lenses and other items, ensuring the integrity of lens performance. The piezoelectric nano-positioning technology, with its unique performance, makes the scale of this coordinate system clearer and more stable.

(Note: Image from online resources)

I. Laser Interferometer: Use the Wavelength of Light as Rule

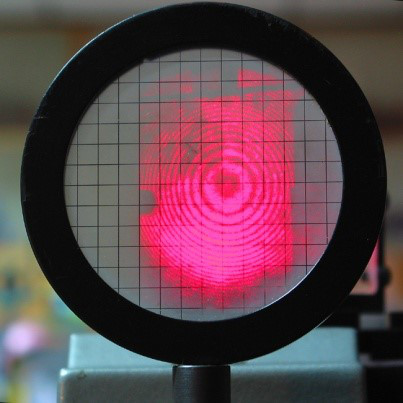

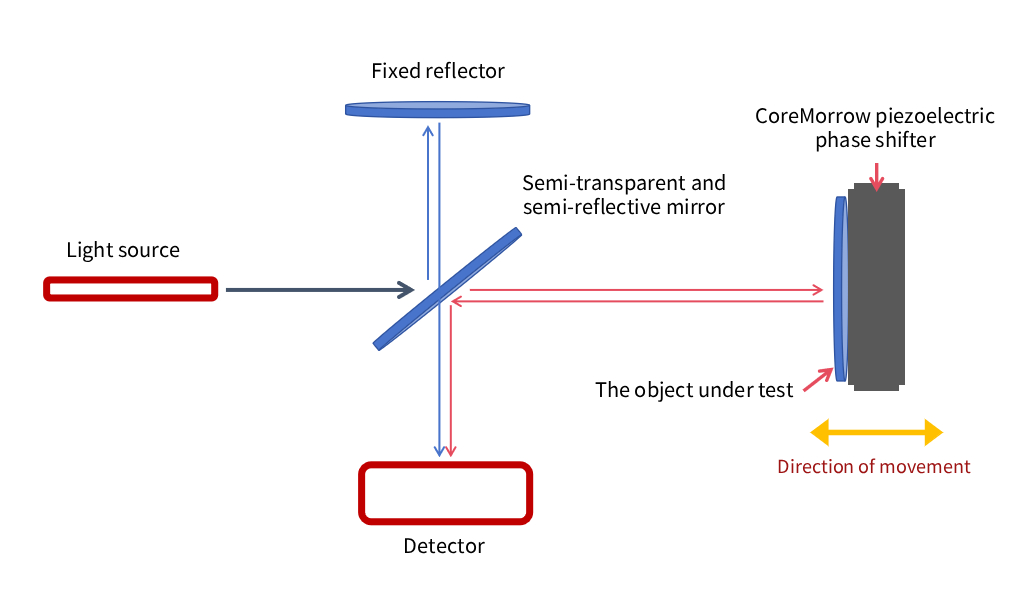

The core principle of a laser interferometer is to utilize the interference of light. By measuring the change in the distance difference between two coherent light beams, it achieves high-precision measurement of physical quantities such as displacement, angle, and flatness. Specifically, it divides a laser beam into two: one follows a fixed reference light path, and the other follows the measurement light path of the moving object under test. When two beams of light meet again, interference fringes will be produced due to the path difference. Then, by calculating the changes in the fringes, the displacement, angle difference and surface flatness of the object being measured can be calculated.

Interference fringe

(Note: Image from online resources)

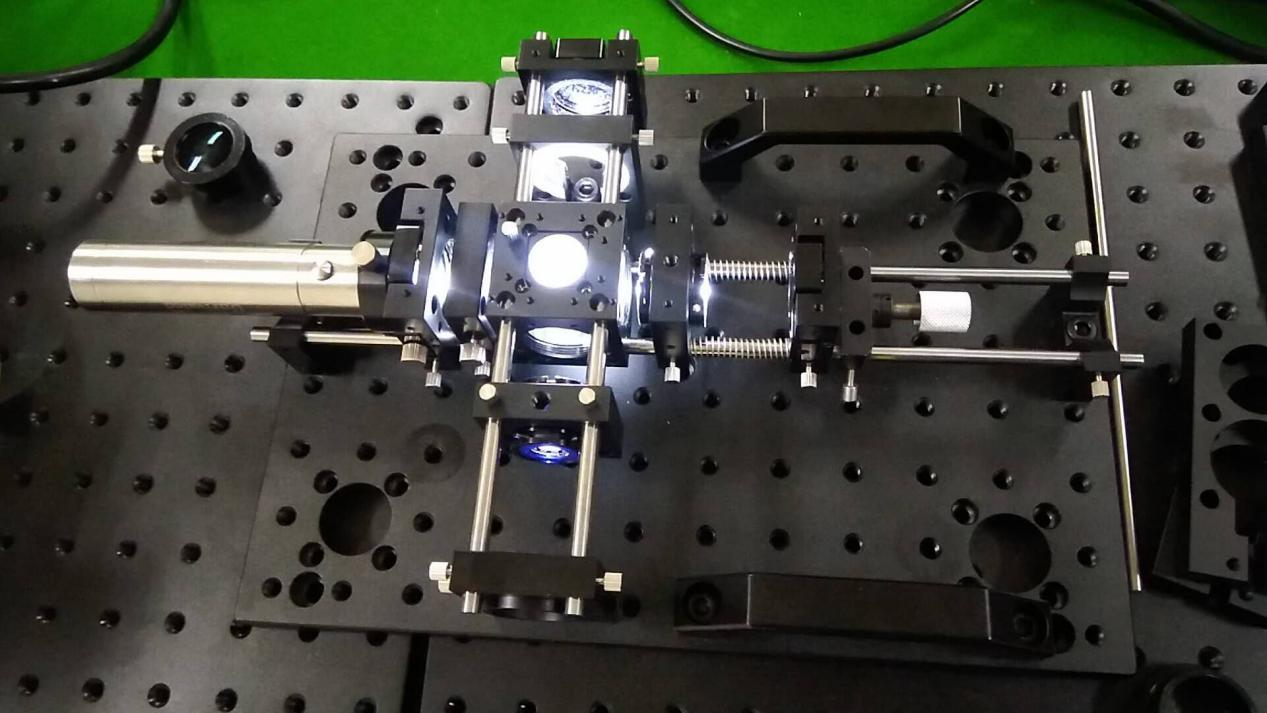

The accuracy of a laser interferometer cannot be achieved without the coordination of four core components:

1.Laser: The laser emission device is the foundation of the interferometer, used to provide a light source with extremely strong monochromaticity and coherence. Only when the light is stable can the accuracy of the measurement be guaranteed.

2.Main part of the interferometer: Responsible for beam splitting and combining, such as the Michelson interference structure, which determines the generation mode of interference fringes.

3.Detector: It captures the changes in interference fringes, converts optical signals into electrical signals, and serves as a monitor for reading measured values.

4. Positioning and adjustment system: Controls the minute postures of the reference mirror and the measuring mirror, such as angles and positions, as well as drives the movement of the object under test.

Among them, the role of the positioning adjustment system is extremely crucial, as the measurement accuracy of the laser interferometer can be significantly affected by even minor vibrations, optical path offsets, and environmental disturbances. For instance, even if the reference mirror is offset by 0.01 microns, the interference fringes will be distorted and the measurement result will be directly invalidated. This is like when observing cells under a microscope, if the objective lens suddenly moves or the stage shakes, the field of vision will become blurred. The laser interferometer measures nanoscale displacements, and the requirements for the positioning system are extremely strict.

II. CoreMorrow Piezo Nano Positioning Technology - More Stable and More Accurate

CoreMorrow piezo nano-positioning technology provides a key solution for meeting the high-precision phase shifting requirements of laser interferometers. The measurement of a laser interferometer utilizes phase-shifting interferometry, which requires extremely precise, linear, and known phase steps. The piezo nano-positioning stage (PZT) precisely meets the requirements for displacement control with nanoscale precision within the micrometer range.

The piezo nano-positioning stage can be controlled by a piezo controller to easily achieve multiple (such as 4, 5, 7 times, etc.) equal-step phase shifts, quickly collect multiple interference patterns, and then calculate the precise phase distribution on the surface of the object under test through algorithms (such as phase shift algorithms), thereby obtaining its flatness information.

Diagram of the optical path of Michelson interferometer

The Core Capabilities of CoreMorrow Piezo Technology Perfectly Meet the Requirements of Laser Interferometers:

1.Nanometer positioning accuracy

It features high positioning accuracy, meeting the minor adjustment requirements during the measurement process, and can perform sub-nanometer-level step phase shifting.

2.Millisecond response speed

The response time of the piezo nano-positioning stage can reach the millisecond level, and it can perform rapid equal-length step operations.

3.Ultra-high stability

The integrated structural design offers high rigidity and high load capacity, with a load capacity of up to over 25kg. It is suitable for phase shift adjustment of both small and large lenses.

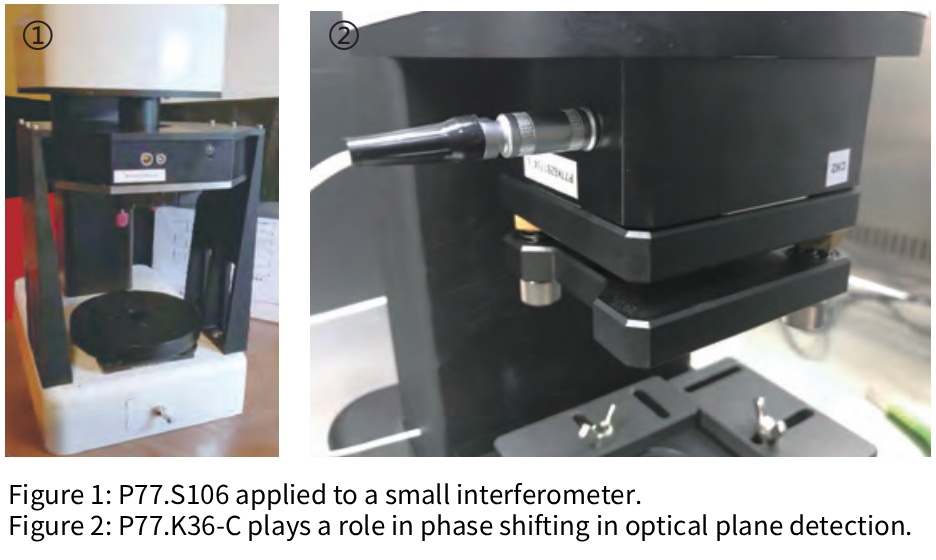

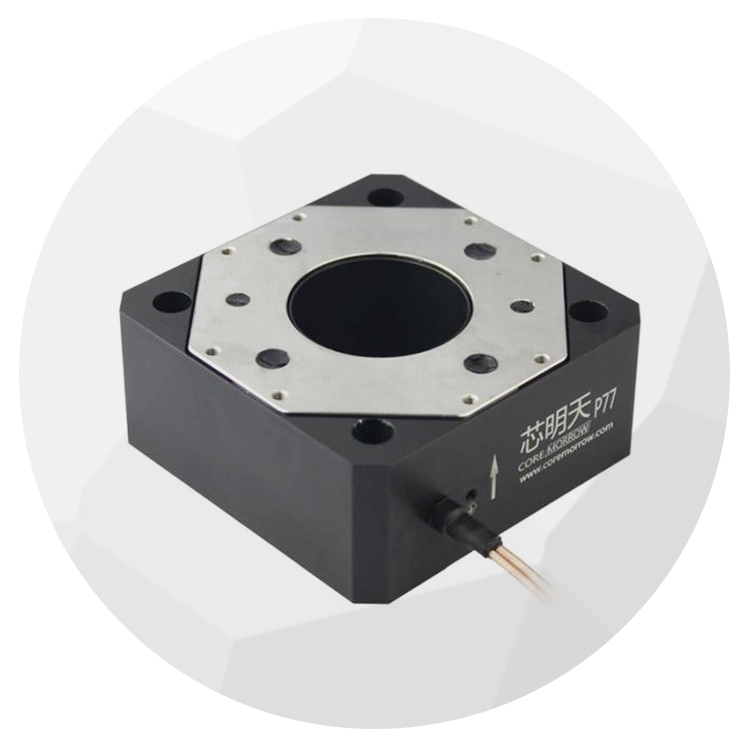

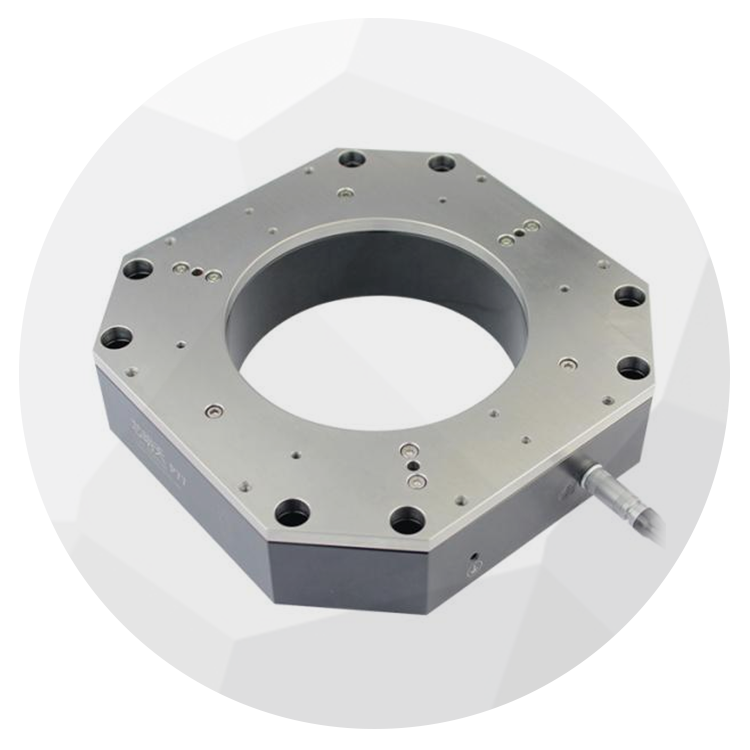

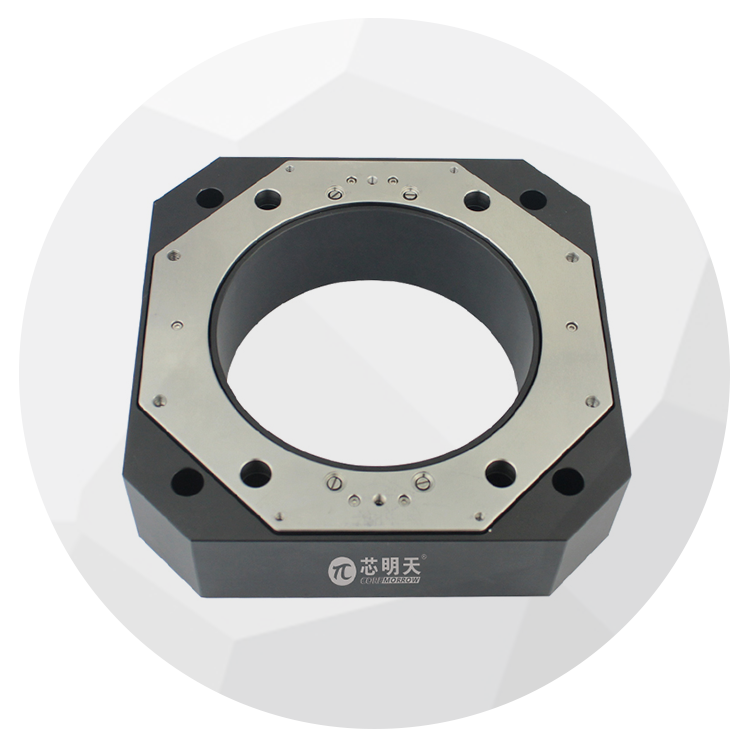

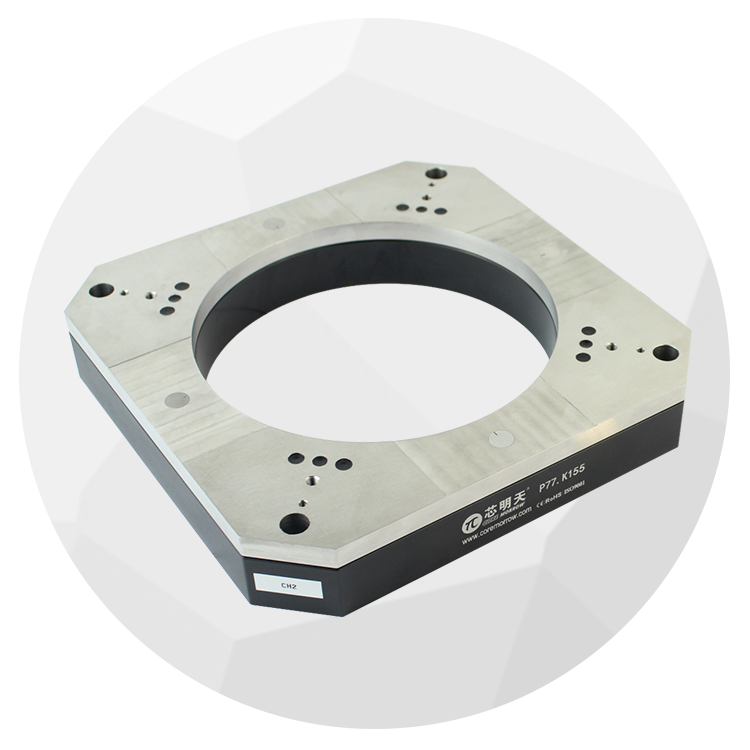

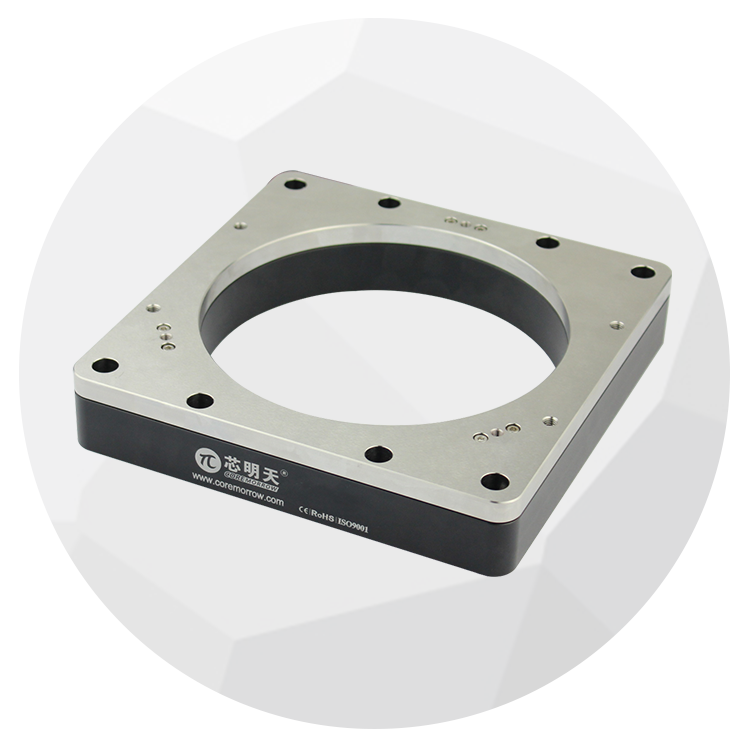

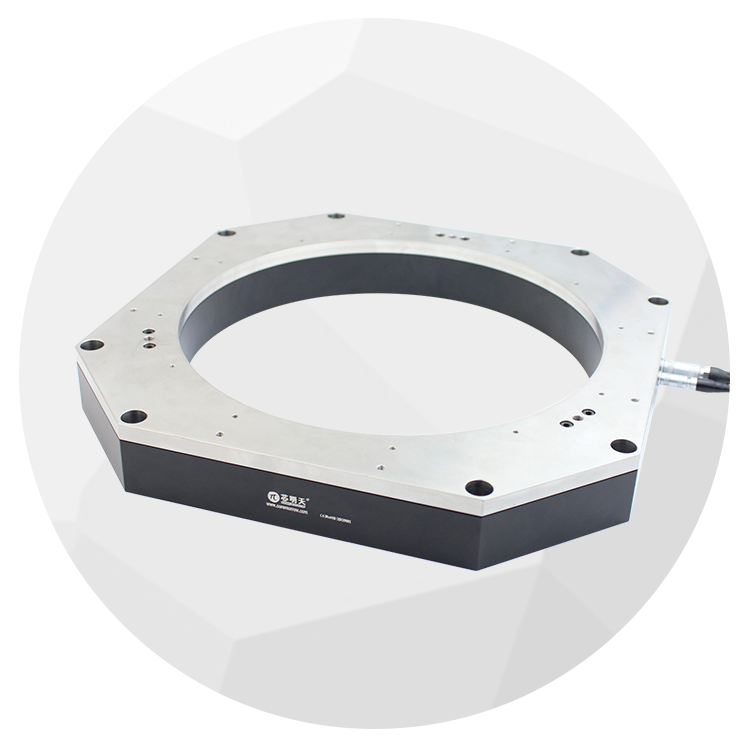

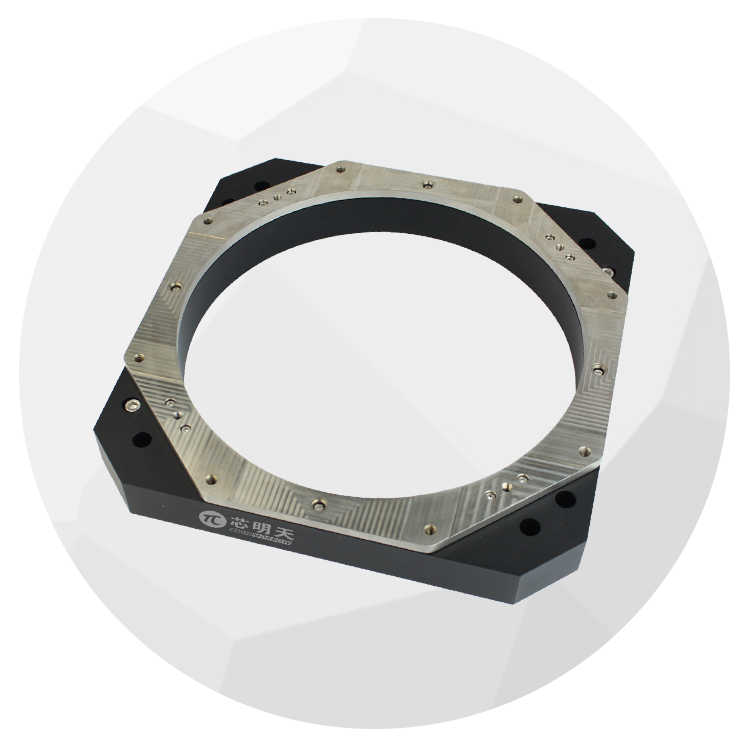

P77 Large-Load Piezo Nano-Positioning Stage

CoreMorrow P77 large-load piezo nano positioning stage/phase shifter is specially designed for optical inspection phase shifting applications. It has a travel range of 100µm and a load capacity of up to 25kg, making it highly suitable for optical inspection equipment of various lenses and shots. The P77 piezo nano-positioning stage is often used in laser plane interferometers (Fischell interferometers) to detect the surface flatness, parallelism and uniformity of optical components such as lenses and mirror surfaces. The P77 series can be customized with the size of the center through hole according to the customer's lens inspection requirements.

characteristics

Travel range: 0-100μm

Through hole diameter: Φ36 to Φ310mm

The load-bearing capacity can be up to 25 kg

It can be installed horizontally, vertically or inverted

Custom service available

Vacuum version is available

P77.S36-C

Stroke: 17.5μm

Aperture: Φ36mm

Resolution: 0.5nm

Load capacity: 7kg

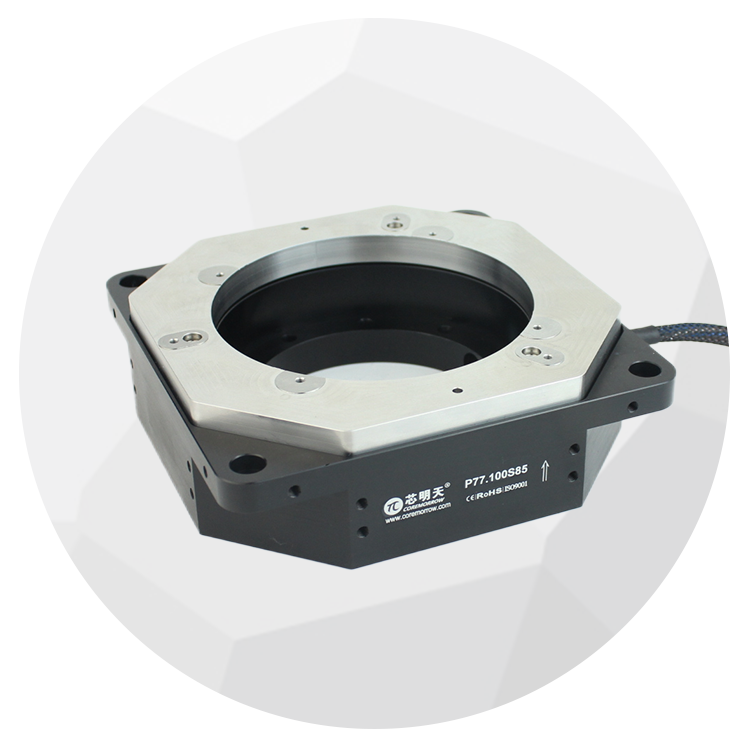

P77.100S85

Stroke: 100μm

Aperture: Φ85mm

Resolution: 3.5nm

Load capacity: 3kg

P77.S106

Stroke: 17.5μm

Aperture: Φ106mm

Resolution: 0.5nm

Load capacity: 15kg

P77.30S140

Stroke: 16μm

Aperture: Φ140mm

Resolution: 0.5nm

Load capacity: 5kg

P77.S155

Stroke: 17μm

Aperture: Φ155mm

Resolution: 0.5nm

Load capacity: 25kg

P77.S160

Stroke: 17.5μm

Aperture: Φ160mm

Resolution: 0.5nm

Load capacity: 10kg

P77.S210

Stroke: 17.5μm

Aperture: Φ210mm

Resolution: 0.5nm

Load capacity: 10kg

P77.S242

Stroke: 17.5μm

Aperture: Φ242mm

Resolution: 0.5nm

Load capacity: 15kg

P77.S310

Stroke: 17μm

Aperture: Φ310mm

Resolution: 0.5nm

Load capacity: 22kg

P77A.S23

Stroke: 16.5μm

Aperture: Φ23mm

Resolution: 0.5nm

P77A.S50

Stroke: 17μm

Aperture: Φ49mm

Resolution: 0.5nm

Load capacity: 5kg

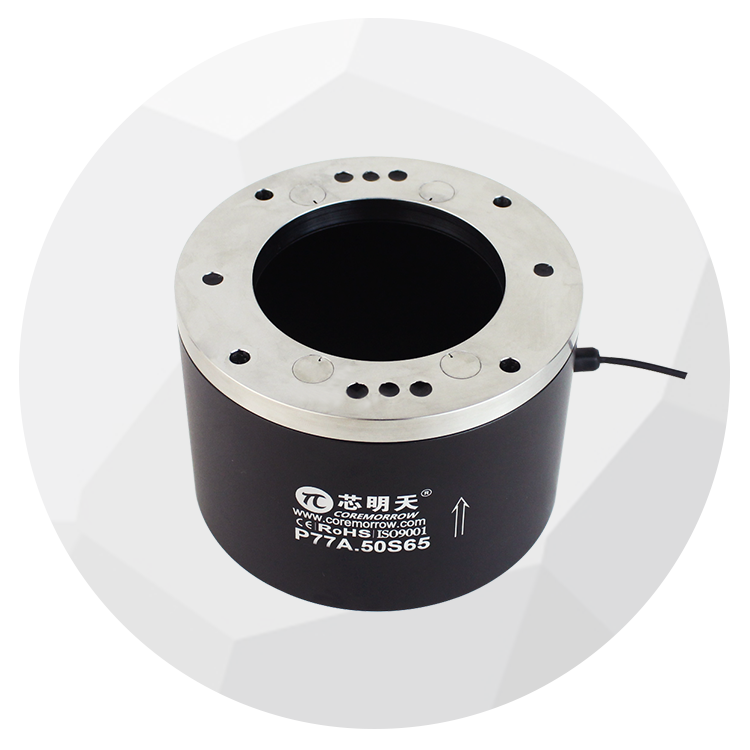

P77A.50S65

Stroke: 43μm

Aperture: Φ65mm

Resolution: 1.5nm

Load capacity: 3kg

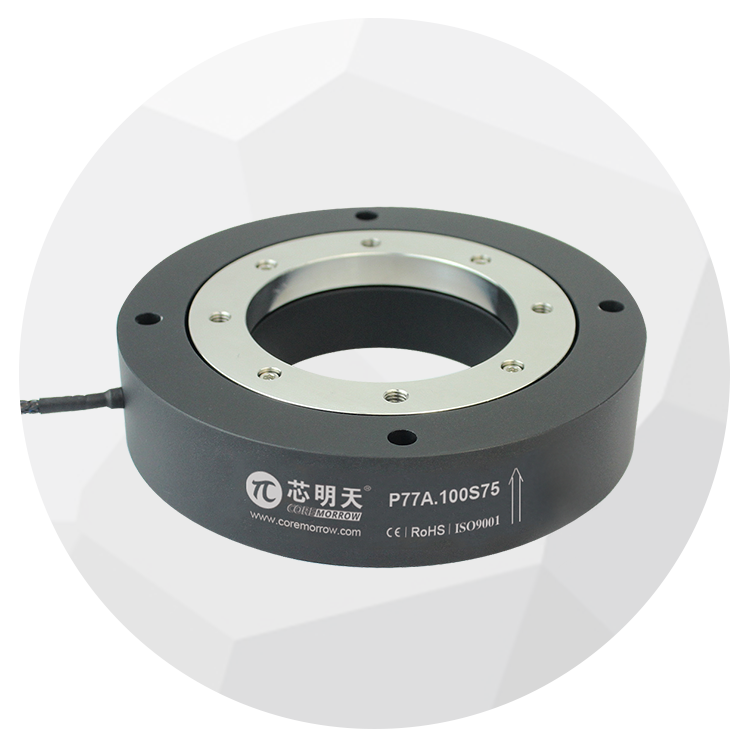

P77A.100S75

Stroke: 100μm

Aperture: Φ75mm

Resolution: 3nm

Load capacity: 3kg

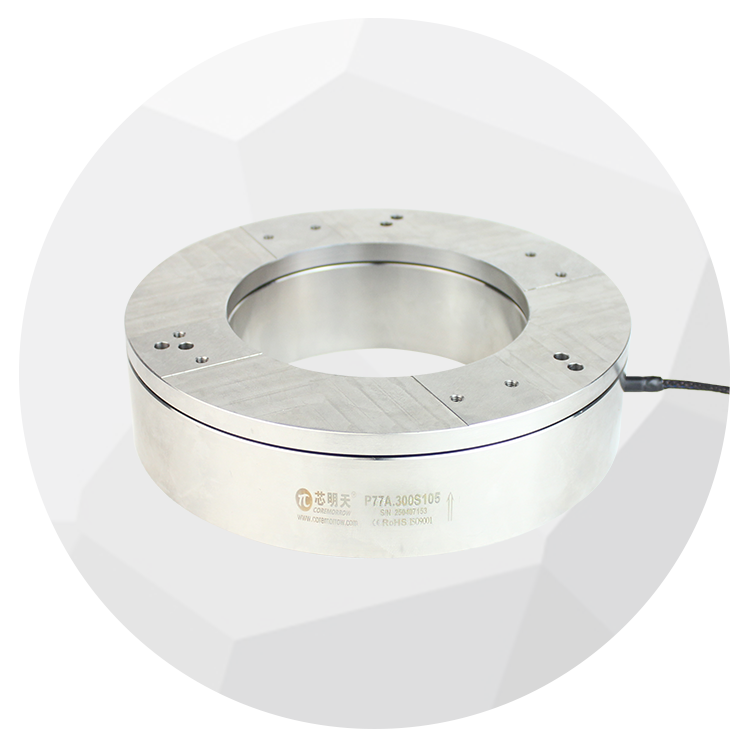

P77A.300S105

Stroke: 475μm

Aperture: Φ105mm

Resolution: 15nm

Load capacity: 0.5kg

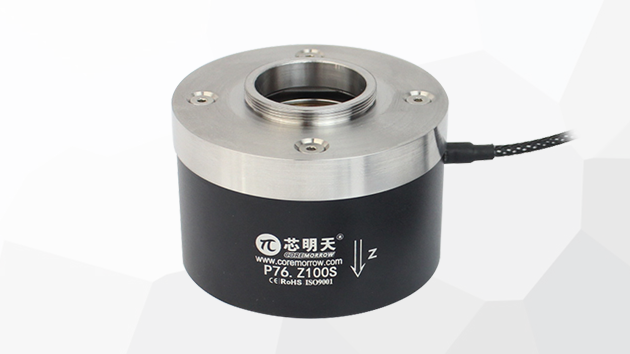

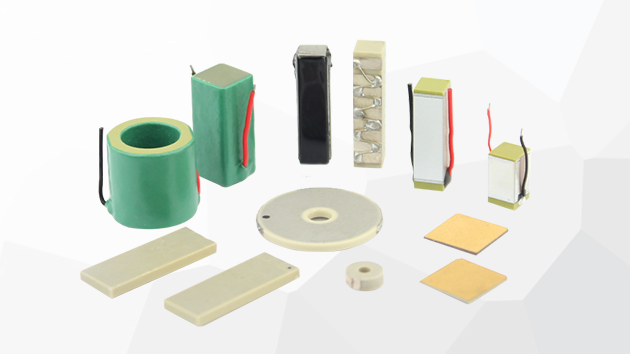

Other Solutions

Piezo nano positioning stage

Piezo objective scanner

Piezoelectric ceramic actuator

Piezo Stacks

- Previous article:No more

- Next article:Piezo Nano-Positioning: Cell Min-Invasive Rev (Centesis & Membrane Rupture)