Precise Drive is the Core - Highlights of CoreMorrow Piezo Controllers

In the field of nanoscale precision positioning, piezo controllers are undoubtedly the control hubs. Its performance directly determines the accuracy, stability and response speed of the piezo nano-positioning system. CoreMorrow adheres to the principle of independent core technology and has developed multiple series of piezo controllers to meet the diverse needs from basic research to high-end industrial fields, creating a series of piezo controller products covering multiple applications and demands.

I.

What is a Piezo Controller ?

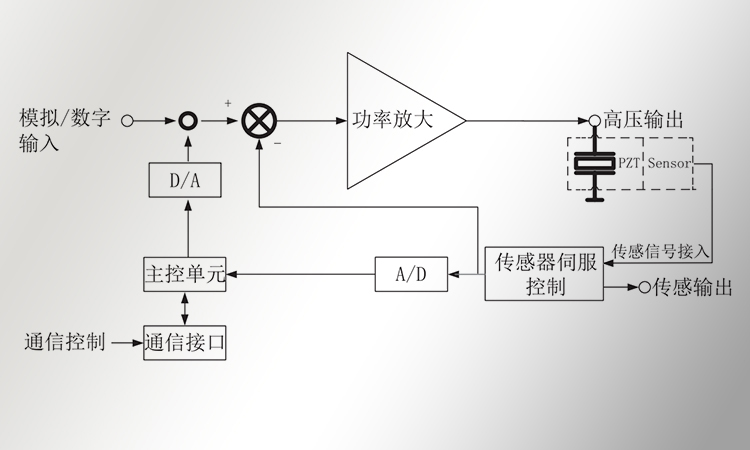

The basic function of a piezo controller is to amplify weak control signals (such as 0-10V) to high voltages (such as 0-150V, 500V...). It is the core device for controlling piezo ceramics to undergo micrometer or even nanometer-level deformation (2000V or even higher). It has very low power consumption, with nearly zero power consumption during static maintenance. Moreover, it is not affected by magnetic fields and can operate stably in special environments. The piezo controller is like the nerve center of precision equipment. Through stable voltage output, fast response speed and precise feedback regulation, it achieves ultra-high-precision precise control in high-end fields such as semiconductor manufacturing, optical engineering and medical equipment, and is a key component of nanoscale positioning technology.

The driving principle of piezo controllers

II.

Core Functions and Applications of Piezo Controllers

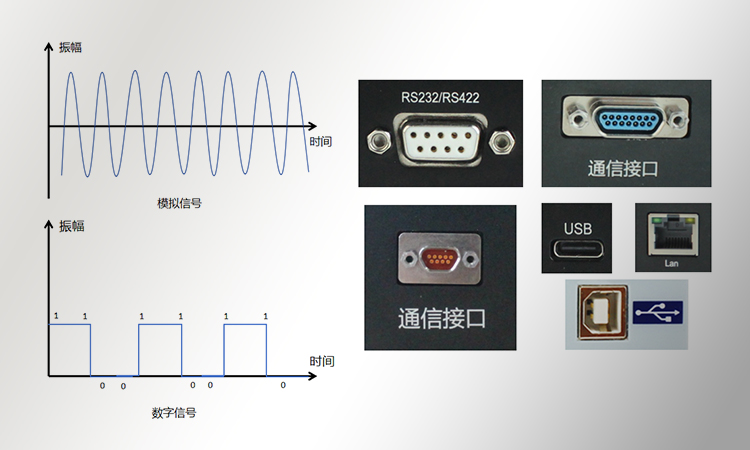

Multi-mode compatibility: Supports analog/digital signal control, adapting to operational requirements in different scenarios;

Intelligent interconnection: Compatible with multiple communication interfaces, supporting secondary development of upper computer software, and flexible integration;

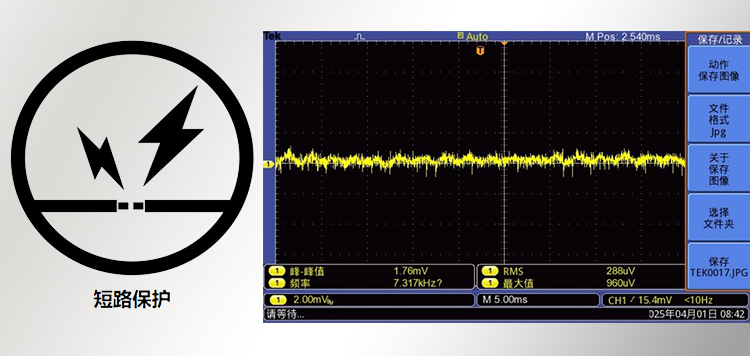

Safe and reliable: Equipped with multiple protections such as short-circuit protection and overcurrent protection, it is suitable for complex working environments.

Exclusive adaptation: Custom drive solutions for products with different load requirements such as piezo positioning stages, scanning stages, and fast steering mirrors;

Precision drive: It provides high stability, high resolution and low ripple voltage output for capacitive loads such as piezo ceramics, ensuring control accuracy and achieving precise displacement.

III.

CoreMorrow Self-Developed Piezo Controllers

The E01.D3K02 is equipped 24-bit high-precision D/A converter, with an output voltage resolution of one millionth of the full scale, providing extremely precise control for microscopic research. It supports multiple communication interfaces such as RS-232/422 and USB-B, and is convenient to connect with the host computer with strong compatibility. It features a static ripple as low as 5mV, ensuring the output voltage signal is pure and stable.

The E01.D3K02 is equipped 24-bit high-precision D/A converter, with an output voltage resolution of one millionth of the full scale, providing extremely precise control for microscopic research. It supports multiple communication interfaces such as RS-232/422 and USB-B, and is convenient to connect with the host computer with strong compatibility. It features a static ripple as low as 5mV, ensuring the output voltage signal is pure and stable.

E01.D3K02

Channels: 3

Output voltage: 0~150V

Computer interface: RS-232/422, USB-B

Amplifier(-3dB)bandwidth: 10kHz

Core advantages: High resolution and high stability

Applicable scenarios: Universal multi-channel piezoelectric drive, suitable for scientific research and metrology fields with high-precision requirements.

The E71.D12E-H piezo controller can simultaneously drive 3 CoreMorrow N31 series linear piezo motor displacement stages, easily handling complex multi-degree-of-freedom positioning tasks. Moreover, it also offers rich secondary development support (VC++, Matlab, LabView), making it easy to integrate into an automated system. With a rated output power of 140W, it provides strong driving force.

E71.D12E-H

Computer interface: RS-422(DB9)

Core advantage: Powerful multi-axis synchronous control capability

Applicable scenarios: High-end industrial and scientific research applications that require multiple piezo motors to work in coordination, such as biological operations and scanning detection.

E80.D3S-S has a wide operating temperature range (-45℃ to +75℃), is specially designed for special environments, and features high reliability. It is specially optimized for driving piezo fast steering mirrors/deflection mirrors and contains a constant voltage output, making it highly suitable for differential driving. In addition, the compact metal shell design can also help dissipate heat efficiently.

E80.D3S-S

Channels: 3

Output voltage: 0 to 120V

Amplifier bandwidth: 1kHz/channel

Communication interface: RS-422

Core advantages: Wide temperature range operation and high reliability

Applicable scenarios: Aerospace, in-vehicle stability platforms and other fields with harsh environmental conditions.

E80.B33-K is a 3-channel piezo controller, with each channel featuring a 10kHz amplifier bandwidth. It offers a fast response speed and is suitable for dynamic high-frequency applications. Moreover, the pure analog control mode can achieve no digital delay and has stronger real-time performance. It also supports differential drive, with selectable output voltage (0~100V/120V), flexibly adapting to different loads.

E80.B3S-K

Channels: 3

Output voltage: 0 to 100V

Control mode: Analog control

Amplifier bandwidth: 10kHz

Core advantages: High bandwidth and analog control

Applicable scenarios: Vibration compensation, active vibration isolation, laser beam stabilization and other scenarios with high requirements for response speed.

E53.D1S-I is equipped with an 8-inch full-color LED touch screen, allowing for parameter setting, data storage and retrieval without a computer. The operation is intuitive and convenient. Moreover, it has a compact structure and small size, combining the convenience of desktop control with its small size. And it supports multiple communication methods such as USB (Type-C) and RS-232/422.

E53.D1S-I

Channels: 1

Output voltage: -20V to 120V (-20V to 150V optional)

Amplifier bandwidth: 10kHz

Communication interface: USB (Type-C), RS-232/422

Core advantages: Integrated touchscreen and portable design

Applicable scenarios: System integration, front-end control of equipment, on-site debugging, and scientific research experiments that require independent operation, etc.

E53.D2E-K features compact and integrated design, which saves a lot of space and easy to carry and move around. It supports two control modes: handle control and upper computer control, allowing for free and flexible movement operations. It can drive two linear piezo motors simultaneously and is an ideal choice for achieving portable precision motion.

E53.D2E-K

Channels: 2

Static power consumption: < 5W

Communication interfaces: TYPE-C, RS-422, RS-232

Control mode: Digital signal control/Handle control

Core advantage: Handheld integrated design

Applicable scenarios: Teaching demonstrations, on-site maintenance, integration of miniaturized equipment, and other occasions with limited space or requiring mobile control.

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.

- Previous article:No more

- Next article:How to Unlock LED Chip Repair & Precision Probe Station—N11 Piezo Motor Stage